ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (11): 2704-2709.DOI: 10.3969/j.issn.1004-132X.2025.11.028

• 智能制造 • 上一篇

杨权印1( ), 张宇宁1, 肖铜1, 梁金龙1, 王金涛2, 徐金亭1(

), 张宇宁1, 肖铜1, 梁金龙1, 王金涛2, 徐金亭1( )

)

收稿日期:2024-10-25

出版日期:2025-11-25

发布日期:2025-12-09

通讯作者:

徐金亭

作者简介:杨权印,男,2000年生,硕士研究生。研究方向为机器人加工技术。E-mail: 15670882921@163.com基金资助:

Quanyin YANG1( ), Yuning ZHANG1, Tong XIAO1, Jinlong LIANG1, Jintao WANG2, Jinting XU1(

), Yuning ZHANG1, Tong XIAO1, Jinlong LIANG1, Jintao WANG2, Jinting XU1( )

)

Received:2024-10-25

Online:2025-11-25

Published:2025-12-09

Contact:

Jinting XU

摘要:

针对轮毂来料一致性差、三维模型缺失、仅有二维CAD图形等问题,提出CAD图形制导的机器人打磨路径自适应生成方法,实现轮毂孔侧缘毛刺的光滑去除。首先,根据CAD主、剖视图点位对应关系快速提取打磨理论路径,并采用二维工业相机获取轮毂孔的实际二维轮廓,建立其与理论路径的配准模型,同时提出基于邻域点加权平均的实际二维轮廓深度信息还原方法,生成自适应打磨路径。然后,给出基于三次B样条曲线的打磨路径点拟合光顺方法,和基于球面四边形插值的工具姿态优化模型,保证曲率变化大、难加工区域打磨连续平稳。实验结果表明,所提方法生成路径连续、运动平稳且无姿态突变,相比理论路径精度提高了90%以上,生产节拍平均为88 s,满足企业生产要求。

中图分类号:

杨权印, 张宇宁, 肖铜, 梁金龙, 王金涛, 徐金亭. CAD图形制导的汽车轮毂机器人打磨路径生成方法[J]. 中国机械工程, 2025, 36(11): 2704-2709.

Quanyin YANG, Yuning ZHANG, Tong XIAO, Jinlong LIANG, Jintao WANG, Jinting XU. Robotic Grinding Path Generation Method Guided by CAD for Automobile Wheel Hubs[J]. China Mechanical Engineering, 2025, 36(11): 2704-2709.

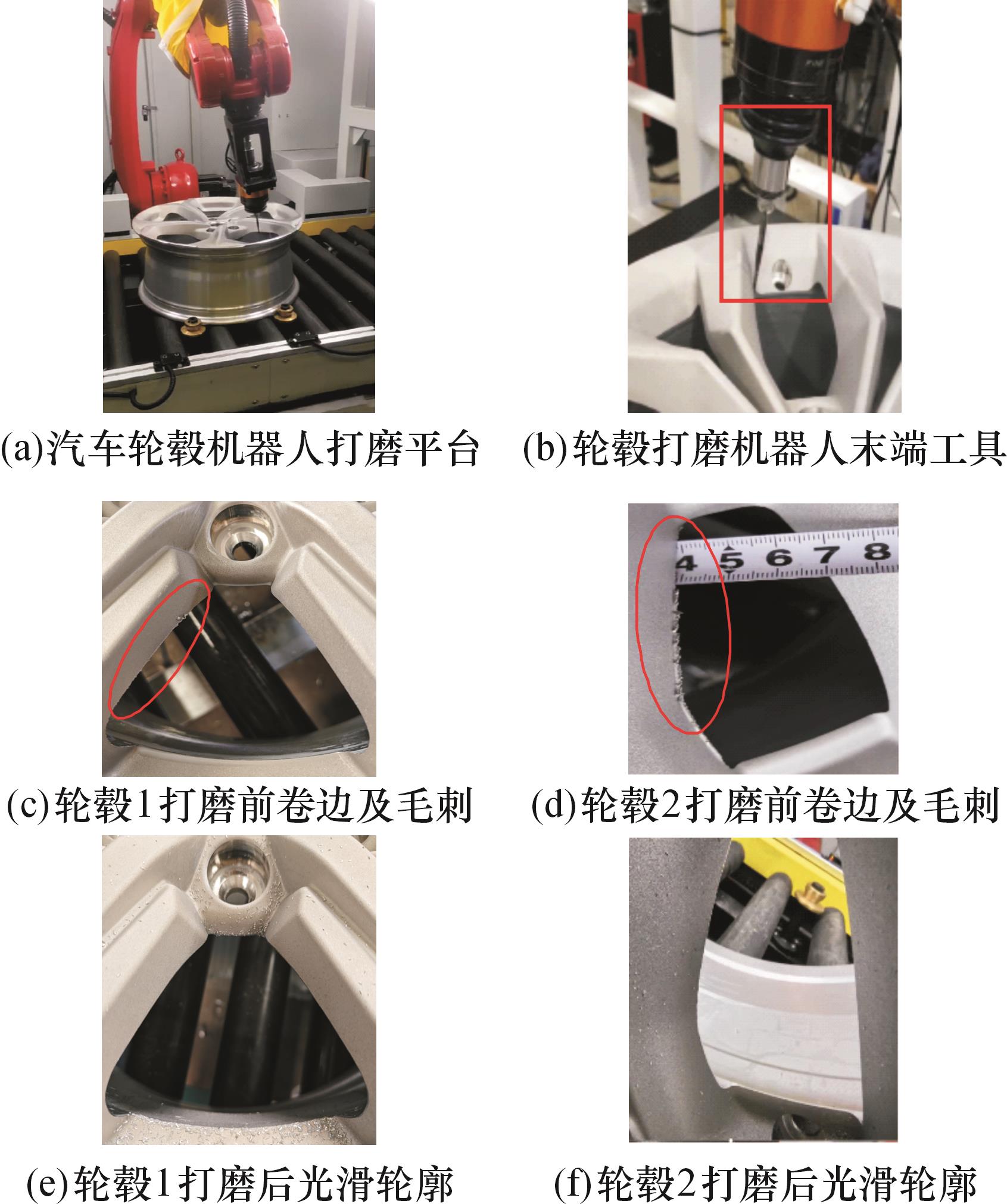

图7 汽车轮毂机器人打磨平台及两款轮毂打磨前后的实验结果对比

Fig. 7 Automobile wheel hub robotic grinding platform and comparison of experimental results before and after grinding of two type wheel hubs

| 参数 | 理论路径与测量路径误差D1/mm | 调整路径与测量路径误差D2/mm | 路径精度提升百分比/ % | |

|---|---|---|---|---|

| 轮毂1 | 最大误差 | 1.7632 | 0.2016 | 88.57 |

| 最小误差 | 0.1818 | 0.0049 | 97.30 | |

| 平均误差 | 0.7094 | 0.0589 | 91.70 | |

| 轮毂2 | 最大误差 | 2.4115 | 0.1990 | 91.75 |

| 最小误差 | 0.1657 | 0.0155 | 90.65 | |

| 平均误差 | 1.1668 | 0.0712 | 93.90 | |

表1 轮毂打磨路径调整前后的误差分析

Tab.1 Error analysis of wheel hub grinding paths before and after adjustment

| 参数 | 理论路径与测量路径误差D1/mm | 调整路径与测量路径误差D2/mm | 路径精度提升百分比/ % | |

|---|---|---|---|---|

| 轮毂1 | 最大误差 | 1.7632 | 0.2016 | 88.57 |

| 最小误差 | 0.1818 | 0.0049 | 97.30 | |

| 平均误差 | 0.7094 | 0.0589 | 91.70 | |

| 轮毂2 | 最大误差 | 2.4115 | 0.1990 | 91.75 |

| 最小误差 | 0.1657 | 0.0155 | 90.65 | |

| 平均误差 | 1.1668 | 0.0712 | 93.90 | |

| [1] | 雷雨, 许志龙, 徐西鹏, 等. 微切削结构毛刺研究综述[J]. 机械工程学报, 2024, 60(21): 336-348. |

| LEI Yu, XU Zhilong, XU Xipeng, et al. A Review of Burr Research of Microstructures in Micro Cutting[J]. Journal of Mechanical Engineering, 2024, 60(21): 336-348. | |

| [2] | 吴振国. 汽车的轻量化铝合金轮毂生产工艺研究[J].装备制造技术, 2024(6): 167-170. |

| WU Zhenguo. Research on Lightweight Aluminum Alloy Wheel Production Process for Automobiles[J]. Equipment Manufacturing Technology, 2024(6): 167-170. | |

| [3] | 卢晓红, 洛家庆, 丛晨, 等. 铝合金 LF21 微铣削顶端毛刺尺寸预测与工艺优化[J]. 吉林大学学报(工学版), 2025, 55(1): 125-131. |

| LU Xiaohong, LUO Jiaqing, CONG Chen, et al. Prediction of Top Burr Size and Optimization of Process Parameters in Micro-milling Aluminum Alloy LF21[J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 125-131. | |

| [4] | 李蕊, 李云革. 基于机器人视觉和力控技术的汽车轮毂打磨系统研究[J]. 汽车测试报告, 2023(21): 143-145. |

| LI Rui, LI Yunge. Research on Automotive Wheel Grinding System Based on Robot Vision and Force Control Technology[J]. Car Test Report, 2023(21): 143-145. | |

| [5] | 葛吉民, 邓朝晖, 李尉, 等. 机器人磨抛力柔顺控制研究进展[J]. 中国机械工程, 2021, 32(18): 2217-2230. |

| GE Jimin, DENG Chaohui, LI Wei, et al. Research Progresses of Robot Grinding and Polishing Force Compliance Controls[J]. China Mechanical Engineering, 2021, 32(18): 2217-2230. | |

| [6] | 汤彬康, 何震宇, 张永喆, 等. 汽车轮毂瑕疵智能检测系统的设计与开发[J]. 福建电脑, 2021, 37(7): 85-87. |

| TANG Binkang, HE Zhenyu, ZHANG Yongzhe, et al. Design and Development of Intelligent Detection System for Automobile Hub Defects[J]. Journal of Fujian Computer, 2021, 37(7): 85-87. | |

| [7] | 傅诤之. 机器人铣削去毛刺加工效率优化研究[J]. 现代制造技术与装备, 2023,59(8): 187-189. |

| FU Zhengzhi. Research on Optimization of Burr Removal Efficiency in Robot Milling[J]. Modern Manufacturing Technology and Equipment, 2023, 59(8): 187-189. | |

| [8] | 李想. 基于机器视觉的工件边缘加工轨迹生成与机器人运动规划研究[D].上海:上海交通大学, 2020. |

| LI Xiang. Research on Trajectory Generation and Robot Motion Planning for Workpiece Edge Machining Based on Machine Vision[D]. Shanghai:Shanghai Jiao Tong University, 2020. | |

| [9] | 陈杰, 王宏彦. 基于视觉的汽车轮毂打磨实训系统设计[J].工业仪表与自动化装置, 2021(1): 36-38. |

| CHEN Jie, WANG Hongyan. Design of Practical Training System of Wheel Hub Grinding Based on Vision[J]. Industrial Instrumentation and Automation, 2021(1): 36-38. | |

| [10] | ZHANG Yu, LIU Hongdi, CHENG Weikang, et al. A Novel Trajectory Planning Method for Robotic Deburring of Automotive Castings Considering Adaptive Weights[J]. Robotics and Computer-Integrated Manufacturing, 2024, 86:102677. |

| [11] | 程禛溢, 郭强, 鱼海东. 面向轮毂打磨的机器人冲击最优轨迹规划[J]. 农业装备与车辆工程, 2020, 58(7): 71-75. |

| CHENG Zhenyi, GUO Qiang, YU Haidong. Optimal Trajectory Planning of Impact for Hub Grinding Robot[J]. Agricultural Equipment & Vehicle Engineering, 2020, 58(7): 71-75. | |

| [12] | 徐汝锋, 陈志同, 孟凡军, 等. 基于机床运动学约束球头刀多轴加工刀轴矢量优化方法[J]. 机械工程学报, 2015, 51(23): 160-167. |

| XU Rufeng, CHEN Zhitong, MENG Fanjun, et al. Tool Orientation Optimization Method Based on Kinematics Constraints of the Machine Tool in Multi-axis Machining with a Ball-end Cutter[J]. Journal of Mechanical Engineering, 2015, 51(23): 160-167. | |

| [13] | XU R, LI X, ZHENG G, et al. A Radius Compensation Method of Barrel Tool Based on Macro Variables in Five-axis Flank Machining of Sculptured Surfaces[J]. International Journal of Production Research, 2020,58: 2335-2351. |

| [14] | 卢耀安, 丘洪键, 王成勇. 基于关键刀轴矢量插值的球头铣刀五轴加工光顺刀具姿态生成方法[J]. 中国机械工程, 2023, 34(20): 2466-2474. |

| LU Yaoan, QIU Hongjian, WANG Chengyong. Smooth Tool Orientation Generation Method of Five-axis Ball-end Milling via RTOs Interpolation[J]. China Mechanical Engineering, 2023, 34(20): 2466-2474. | |

| [15] | LU Y A, WANG C Y. Smoothing Method of Generating Flank Milling Tool Paths for Five-axis Flat-end Machining Considering Constraints[J]. International Journal of Advanced Manufacturing Techno-logy, 2020, 110(11/12): 3295-3309. |

| [16] | 赵恒, 周鑫, 张森堂. 基于机床旋转轴角加速度的五轴加工刀轴矢量局部优化[J]. 机床与液压, 2022, 50(11): 94-97. |

| ZHAO Heng, ZHOU Xin, ZHANG Sentang. Local Optimization of Five-axis Machining Tool Orientation Based on Angular Acceleration of Machine Tool[J]. Machine Tool & Hydraulics, 2022, 50(11): 94-97. | |

| [17] | 刘其广, 徐金亭, 徐飞飞, 等. 机床运动性能驱动的五轴加工刀具姿态光顺插值[J]. 机床与液压, 2024, 52(13): 22-26. |

| LIU Qiguang, XU Jinting, XU Feifei, et al. Smooth Interpolation of Tool Posture in Five-axis Machining Based on Kinematics Performance of Machine Tools[J]. Machine Tool & Hydraulics, 2024, 52(13): 22-26. | |

| [18] | 毛文志, 潘通, 李程鹏, 等. 基于球面线性插值的机器人磨削工具姿态规划[J]. 机床与液压, 2023, 51(3): 6-9. |

| MAO Wenzhi, PAN Tong, LI Chengpeng, et al. Tool Posture Planning for Robotic Grinding Based on Spherical Linear Interpolation[J]. Machine Tool & Hydraulics, 2023, 51(3): 6-9. | |

| [19] | ZHAO S, PENG F, SUN H, et al. Robotic Milling Posture Adjustment under Composite Constraints: a Weight-sequence Identification and Optimization Strategy[J].Robotics and Computer-Integrated Ma-nufacturing, 2024, 85: 102635. |

| [20] | 郭万金, 孙浩, 利乾辉, 等. 轮毂窗口毛刺机器人打磨刀路规划与工具姿态优化[J]. 中国机械工程, 2025, 36(6): 1222-1237. |

| GUO Wanjin, SUN Hao, LI Qianhui, et al. Tool Path Planning and Tool Orientation Optimization for Robotic Grinding of Wheel Hub Window Burrs[J]. China Mechanical Engineering, 2025, 36(6): 1222-1237. | |

| [21] | 张龙, 朱学军, 马心知, 等. 融合特征点提取的三维点云配准方法[J]. 应用激光, 2023, 43(12): 139-149. |

| ZHANG Long, ZHU Xuejun, MA Xinzhi, et al. Point Cloud Registration of Industrial Parts Based on Improved Nearest Iteration Points[J]. Applied Laser, 2023, 43(12): 139-149. | |

| [22] | 查云飞, 张坤, 沈磊, 等. 基于NSGA-Ⅱ的智能车辆换道轨迹规划与优化[J]. 汽车工程学报, 2024, 14(6): 970-980. |

| ZHA Yunfei, ZHANG Kun, SHEN Lei, et al. Lane-change Trajectory Planning and Optimization for Intelligent Vehicles Based on NSGA-Ⅱ[J]. Chinese Journal of Automotive Engineering, 2024, 14(6): 970-980. | |

| [23] | BI Q Z, WANG Y H, ZHU L M, et al. Wholly Smoothing Cutter Orientations for Five-axis NC Machining Based on Cutter Contact Point Mesh[J]. Science China Technological Sciences, 2010, 53(5): 1294-1303. |

| [24] | PLAKHOTNIK D, LAUWERS B. Graph-based Optimization of Five-axis Machine Tool Movements by Varying Tool Orientation[J]. The International Journal of Advanced Manufacturing Technology, 2014, 74(1): 307-318. |

| [25] | WANG Q, FENG Y, ZHANG Z, et al. Tool Orientation Sequence Smoothing Method Based on the Discrete Domain of Feasible Orientations[J]. The International Journal of Advanced Manufacturing Technology, 2017, 92(9): 4501-4510. |

| [26] | CASTAGNETTI C, DUC E, RAY P. The Domain of Admissible Orientation Concept: a New Method for Five-axis Tool Path Optimisation[J]. Computer-Aided Design, 2008, 40(9): 938-950. |

| [1] | 战晓磊, 辛洪兵, 汉斯·彼德 兰特斯. 基于虚拟现实的MOTOMAN-HP3型机器人运动学仿真 [J]. J4, 201016, 21(16): 1952-1954,1998. |

| [2] | 张颢曦, 姜杰, 蒋刚, 李月, 郝兴安. 黏土环境下六足机器人抬腿阻滞力学模型研究[J]. 中国机械工程, 2025, 36(9): 1996-2002. |

| [3] | 张益鑫, 苗忆南, 易智恒, 万文静, 王兴坚, 曾松, 王少萍. 新型可变形串联管道检测机器人:设计、建模及实验[J]. 中国机械工程, 2025, 36(9): 2140-2149. |

| [4] | 李浩, 刘欣荣, 刘仪沁, 范狄庆. 基于改进自抗扰控制的高空风机叶片打磨机器人被动柔顺控制方法研究[J]. 中国机械工程, 2025, 36(8): 1832-1841. |

| [5] | 梁海平, 卢耀安, 连伟嘉, 王成勇. 考虑冗余自由度的六轴机器人光顺运动路径规划方法[J]. 中国机械工程, 2025, 36(11): 2652-2657. |

| [6] | 董佳祥, 刘铨权, 胡希平, 赵学智. 新型刚柔混联连续体机器人运动建模[J]. 中国机械工程, 2025, 36(11): 2678-2684. |

| [7] | 戴尧, 曾勇, 赵雪雅, 万俊豪, 顾金彤, 祝欣怡. 凸起凹陷特征表面的机器人变位姿喷涂涂层均匀性优化研究[J]. 中国机械工程, 2025, 36(11): 2694-2703. |

| [8] | 张来喜, 赵杨昊宇, 朱盛杰, 马凯威, 徐丰羽. 双驱动器仿肺软体机器人建模与变形分析[J]. 中国机械工程, 2025, 36(10): 2379-2388. |

| [9] | 宜亚丽1, 2, 程阳洋2, 陈晓卫2, 陈一凡2, 张振东2, 金贺荣1, 2. 基于最大刚度原则的铣削机器人位姿确定方法[J]. 中国机械工程, 2025, 36(07): 1544-1552. |

| [10] | 杨雨1, 2, 李晓雷2, 陶友瑞1, 2, 郭祺雨1, 2, 叶楠1, 2. RV减速器服役工况加速载荷谱编制方法[J]. 中国机械工程, 2025, 36(06): 1170-1177. |

| [11] | 高贯斌1, 2, 赵思郭1, 2, 李映杰1, 2. 基于关节扭矩平衡的机器人末端负载建模及辨识[J]. 中国机械工程, 2025, 36(06): 1188-1197. |

| [12] | 董伟光1, 刘爱华2, 宋屹峰2. 一种新型负压式爬壁机器人吸附特性分析[J]. 中国机械工程, 2025, 36(06): 1198-1205. |

| [13] | 郭万金1, 2, 3, 4, 孙浩1, 利乾辉1, 田玉祥1, 曹雏清2, 赵立军2, 4. 轮毂毛刺机器人打磨刀路规划与工具姿态优化[J]. 中国机械工程, 2025, 36(06): 1222-1237. |

| [14] | 郭万金1, 2, 3, 4, 李儒1, 王利斌1, 郝钦磊1, 曹雏清2, 赵立军2, 4. 一种考虑弱刚性关节传动链结构和柔性杆结构的机器人刚度辨识方法[J]. 中国机械工程, 2025, 36(05): 974-985. |

| [15] | 梁志强1, 2, 陈司晨1, 杜宇超1, 刘宝隆1, 2, 高子瑞1, 乐毅3, 肖玉斌4, 郑浩然1, 仇天阳1, 刘志兵1. 基于变分模态滤波和注意力机制的重载机器人铣削系统颤振辨识方法[J]. 中国机械工程, 2025, 36(05): 1018-1027,1073. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||