ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (9): 1968-1979.DOI: 10.3969/j.issn.1004-132X.2025.09.008

• 机械基础工程 • 上一篇

收稿日期:2024-08-30

出版日期:2025-09-25

发布日期:2025-10-15

通讯作者:

孙兴伟

作者简介:李姗姗,女,1986年生,博士研究生。研究方向为机械摩擦学与表面技术、智能与仿生材料。E-mail:sgdlss@sut.edu.cn基金资助:

Shanshan LI1( ), Xingwei SUN1(

), Xingwei SUN1( ), Heng YANG2, Heting QIAO1

), Heng YANG2, Heting QIAO1

Received:2024-08-30

Online:2025-09-25

Published:2025-10-15

Contact:

Xingwei SUN

摘要:

为研究磁流变液摩擦动力学行为对密封副磨损机理的影响,建立表面粗糙度与铁粉耦合效应下的动态密封磨损模型,利用ANSYS对其进行微观接触力学仿真分析,并通过自制往复式动态密封磨损试验装置测试不同表面粗糙度活塞杆样本在两种介质下的摩擦磨损性能。结果表明,粗糙纹理与铁粉瞬时接触不仅能够缓解O形圈在微凸体交变剪切作用下表面出现的疲劳裂纹,还有助于削弱铁粉对活塞杆产生的微切割效应,使密封副在磁流变液工况下展现出良好的摩擦学性能;铁粉介于抛光样本与O形圈之间长期承受微观纹理施加的横向剪切力及纵向挤压力,迫使大量铁粉嵌入O形圈内部,并在往复运动的活塞杆表面产生明显的犁沟式磨痕,导致系统因两体磨粒磨损而过早引发密封失效。

中图分类号:

李姗姗, 孙兴伟, 杨恒, 乔赫廷. 磁流变液环境下密封副非线性磨损行为研究[J]. 中国机械工程, 2025, 36(9): 1968-1979.

Shanshan LI, Xingwei SUN, Heng YANG, Heting QIAO. Research on Nonlinear Wear Behavior of Sealing Pairs in Magnetorheological Fluid Environment[J]. China Mechanical Engineering, 2025, 36(9): 1968-1979.

| 接触副 | 弹性模量/MPa | 材质 | 泊松比 | 屈服应力/MPa | 硬度 |

|---|---|---|---|---|---|

| O形圈 | 37.98 | NBR | 0.49 | 20.76 | 70 HA |

| 活塞杆 | 193 000 | 316L | 0.31 | 200 | 180 HA |

| 铁粉 | 210 000 | Fe(OH)3 | 0.28 | 175 | 279 HA |

表1 接触副材料力学性能

Tab.1 Mechanical properties of materials of contact pairs

| 接触副 | 弹性模量/MPa | 材质 | 泊松比 | 屈服应力/MPa | 硬度 |

|---|---|---|---|---|---|

| O形圈 | 37.98 | NBR | 0.49 | 20.76 | 70 HA |

| 活塞杆 | 193 000 | 316L | 0.31 | 200 | 180 HA |

| 铁粉 | 210 000 | Fe(OH)3 | 0.28 | 175 | 279 HA |

| 样本 | T01 | T02 | T03 | T04 |

|---|---|---|---|---|

| 制备方式 | 车削 | 车削 | 磨削 | 磨削 |

| 表面粗糙度(μm) | 3.2 | 1.6 | 0.5 | 0.18 |

表2 样本表面粗糙度参数对照表及加工方式

Tab.2 Parameters of surface roughness and machining processes of specimens

| 样本 | T01 | T02 | T03 | T04 |

|---|---|---|---|---|

| 制备方式 | 车削 | 车削 | 磨削 | 磨削 |

| 表面粗糙度(μm) | 3.2 | 1.6 | 0.5 | 0.18 |

| 参数 | 数值 |

|---|---|

| 载液 | 甲基硅油 |

| 铁粉体积分数/% | 25 |

| 铁粉粒度/μm | 1~5 |

| 粒度分布 | 正态分布 |

| 表观黏度/(Pa·s) | 1.5 |

| 密度/(g·cm-3) | 2.65 |

| 最大屈服应力/kPa | 75 |

表3 磁流变液MRF-J25T技术参数

Tab.3 Technical parameters of MRF-J25T

| 参数 | 数值 |

|---|---|

| 载液 | 甲基硅油 |

| 铁粉体积分数/% | 25 |

| 铁粉粒度/μm | 1~5 |

| 粒度分布 | 正态分布 |

| 表观黏度/(Pa·s) | 1.5 |

| 密度/(g·cm-3) | 2.65 |

| 最大屈服应力/kPa | 75 |

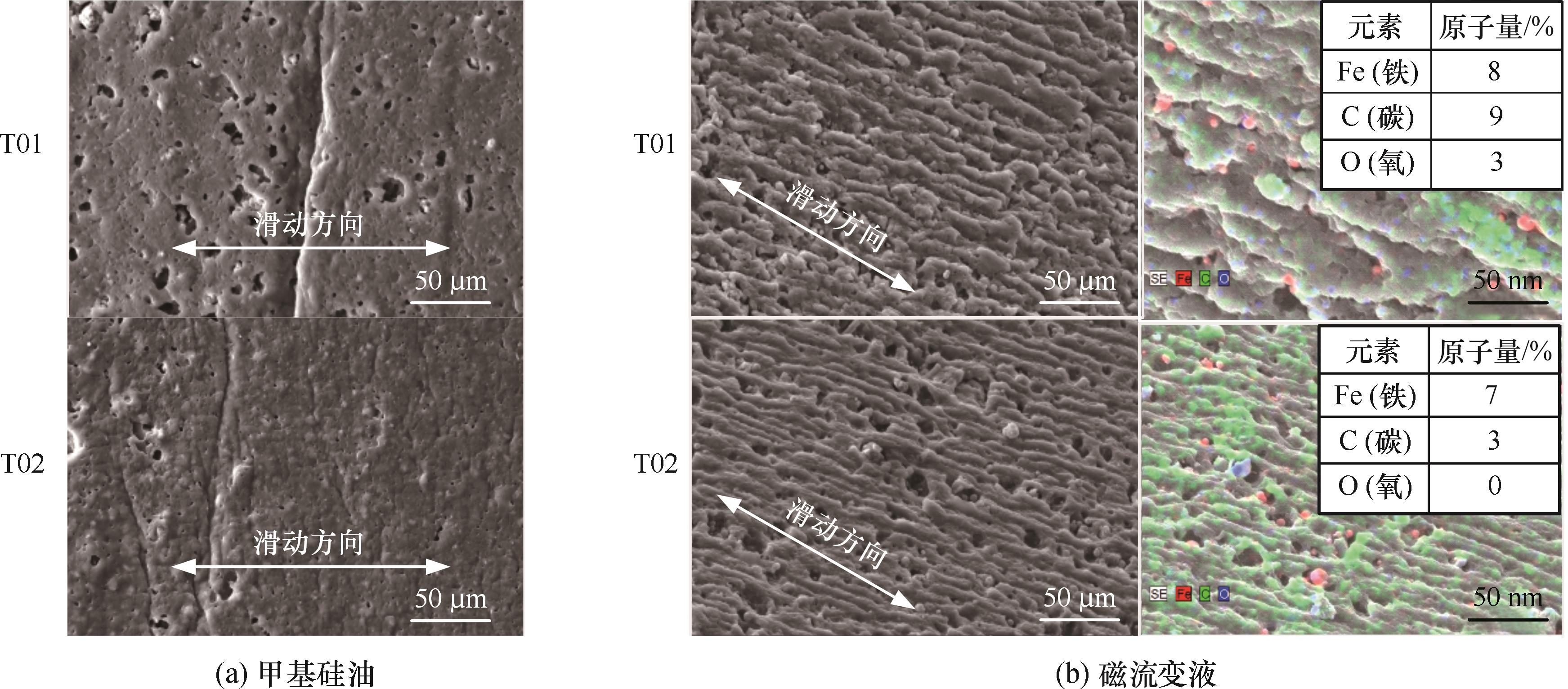

图15 两种试验介质下配副T01、T02对应的O形圈表面磨损形貌及EDS能谱分析

Fig.15 Surface wear morphology and EDS spectrum analysis of O-ring corresponding to T01 and T02 in two test media

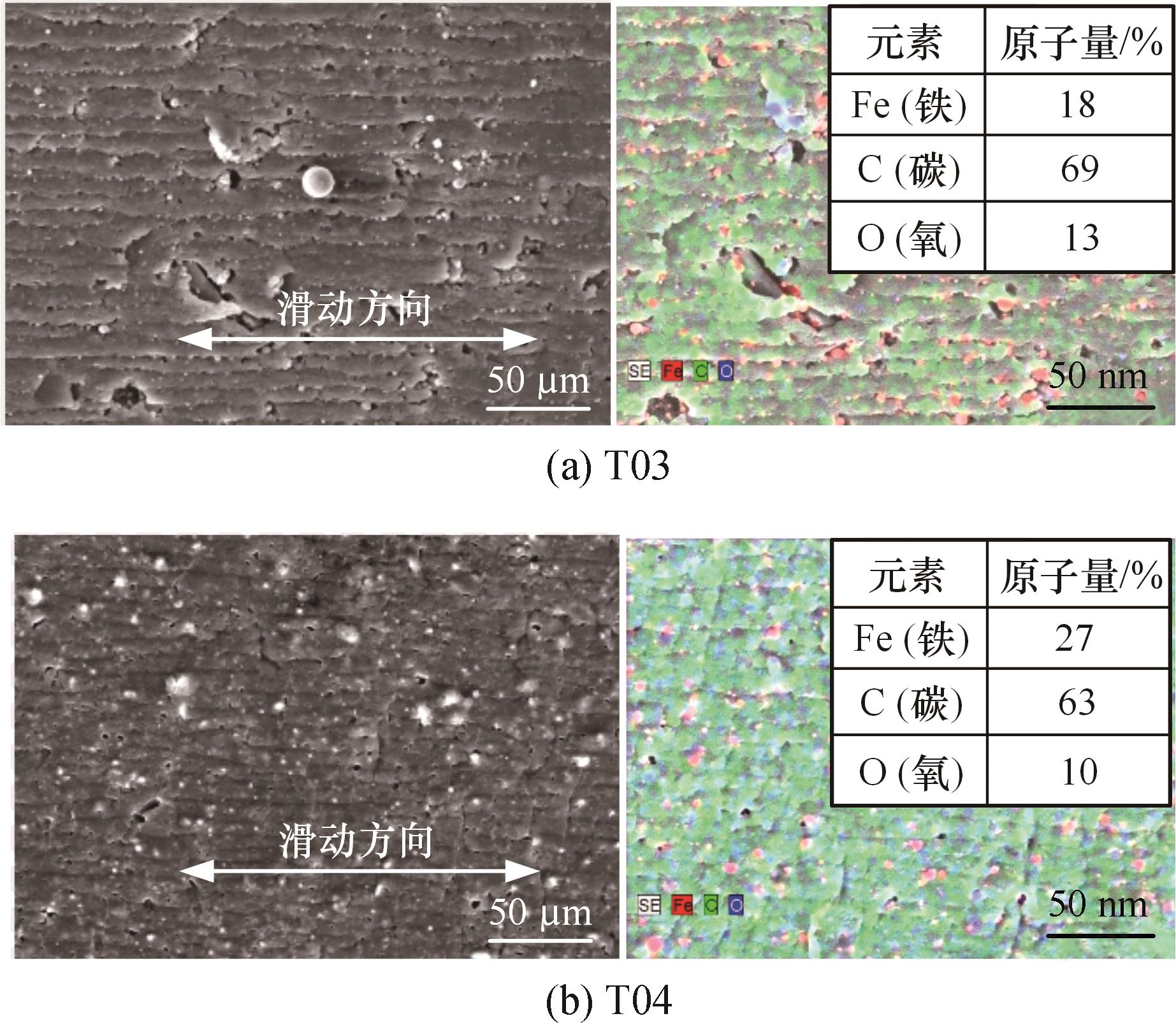

图16 磁流变液工况下配副T03、T04对应的O形圈表面磨损形貌及EDS能谱分析

Fig.16 Surface wear morphology and EDS spectrum analysis of O-ring corresponding to T03 and T04 under MRF condition

| [1] | ESHGARF H, AHMADI NADOOSHAN A, RAISI A. An Overview on Properties and Applications of Magnetorheological Fluids:Dampers, Batteries, Valves and Brakes[J]. Journal of Energy Storage, 2022, 50:104648. |

| [2] | 杨三锋, 黄向明, 明阳, 等. 新型磁流变-剪切增稠阻尼器的力学模型及试验研究[J]. 机械工程学报, 2023, 59(16):418-426. |

| YANG Sanfeng, HUANG Xiangming, MING Yang, et al. Mechanical Model and Experimental Study of a Novel Magnetorheological Shear Thickening Damper[J]. Journal of Mechanical Engineering, 2023, 59(16):418-426. | |

| [3] | 孟凡杰, 王仲楠, 常秋英, 等. 一种可实现超滑的混合溶液的摩擦学研究[J]. 机械工程学报, 2022, 58(11):210-219. |

| MENG Fanjie, WANG Zhongnan, CHANG Qiu-ying, et al. Tribological Investigation of a Mixed Solution with Superlubricity Achieved[J]. Journal of Mechanical Engineering, 2022, 58(11):210-219. | |

| [4] | ZHU Juanjuan, LI Xiangwei, BEAMISH S, et al. An Ultrasonic Method for Measurement of Oil Films in Reciprocating Rubber O-ring Seals[J]. Tribology International, 2022, 167:107407. |

| [5] | 沈明学, 董峰, 彭旭东, 等. 配副金属表面粗糙度对丁腈橡胶O型圈摩擦学特性的影响[J]. 摩擦学学报, 2016, 36(3):320-325. |

| SHEN Mingxue, DONG Feng, PENG Xudong, et al. Effect of Surface Roughness of Metalic Counterpart on Tribological Characteristics of NBR O-ring[J]. Tribology, 2016, 36(3):320-325. | |

| [6] | PERSSON B N J. Theory of Rubber Friction and Contact Mechanics[J]. The Journal of Chemical Physics, 2001, 115(8):3840-3861. |

| [7] | SCARAGGI M, ANGERHAUSEN J, DOROGIN L, et al. Influence of Anisotropic Surface Roughness on Lubricated Rubber Friction:Extended Theory and an Application to Hydraulic Seals[J]. Wear, 2018, 410:43-62. |

| [8] | SILVA A, LENZI V, PYRLIN S, et al. Deep Learning Approach to the Texture Optimization Problem for Friction Control in Lubricated Contacts[J]. Physical Review Applied, 2023, 19(5):054078. |

| [9] | AYMARD A, DELPLANQUE E, DALMAS D, et al. Designing Metainterfaces with Specified Friction Laws[J]. Science, 2024, 383(6679):200-204. |

| [10] | PEÑA-PARÁS L, GAO Hongyu, MALDONADO-CORTÉS D, et al. Effects of Substrate Surface Roughness and Nano/Micro Particle Additive Size on Friction and Wear in Lubricated Sliding[J]. Tribology International, 2018, 119:88-98. |

| [11] | 李星亮, 岳文, 黄飞, 等. 磨料粒度对表面微织构纯钛干摩擦性能的影响[J]. 机械工程学报, 2017, 53(24):25-33. |

| LI Xingliang, YUE Wen, HUANG Fei, et al. Effect of Wear Particle Size on Dry Tribological Properties of Surface Texturing Titanium[J]. Journal of Mechanical Engineering, 2017, 53(24):25-33. | |

| [12] | 沈明学, 李波, 容康杰, 等. 水润滑条件下磨粒尺寸对橡胶密封副摩擦学行为的影响[J]. 摩擦学学报, 2020, 40(2):252-259. |

| SHEN Mingxue, LI Bo, RONG Kangjie, et al. Effect of Abrasive Size on Tribological Behavior of Rubber Sealing Pair under Water-lubricated Conditions[J]. Tribology, 2020, 40(2):252-259. | |

| [13] | SONG Wanli, PENG Zhen, ZHANG Jintao, et al. Effects of Micron-sized Iron Particles on Friction and Wear Behaviors of Seals Used in a Magnetorheological Damper:Analysis and Experiment[J]. Smart Materials and Structures, 2019, 28(9):095019. |

| [14] | SHAHRIVAR K, ORTIZ A L, de VICENTE J. A Comparative Study of the Tribological Performance of Ferrofluids and Magnetorheological Fluids within Steel-Steel Point Contacts[J]. Tribology International, 2014, 78:125-133. |

| [15] | 候丽霞, 刘小君, 张彤, 等. 表面微凹坑和纹理方向对界面摩擦的耦合影响[J]. 中国机械工程, 2017, 28(11):1279-1286. |

| HOU Lixia, LIU Xiaojun, ZHANG Tong, et al. Coupling Effects of Surface Micro-cavity and Textural Directionality on Interface Frictions[J]. China Mechanical Engineering, 2017, 28(11):1279-1286. | |

| [16] | 陈雪辉, 李威, 刘伟, 等. 基于动力学特性的挖掘机工作装置端面摩擦副间隙磨损机理研究[J]. 机械工程学报, 2022, 58(19):191-205. |

| CHEN Xuehui, LI Wei, LIU Wei, et al. Excavator Working Device Based on Dynamic Characteristics Analysis of Clearance Wear Mechanism of End Face Friction Pair[J]. Journal of Mechanical Engineering, 2022, 58(19):191-205. | |

| [17] | LORENZ B, OH Y R, NAM S K, et al. Rubber Friction on Road Surfaces:Experiment and Theory for Low Sliding Speeds[J]. Journal of Chemical Physics, 2015, 142(19):194701. |

| [18] | 王祺德, 刘达新, 刘振宇, 等. 基于复合泄漏通道模型的O型圈密封泄漏率计算方法研究[J]. 机械工程学报, 2023, 59(11):232-241. |

| WANG Qide, LIU Daxin, LIU Zhenyu, et al. A Leakage Rate Calculation Method for O-ring Seal Based on Compound Leakage Channel Model[J]. Journal of Mechanical Engineering, 2023, 59(11):232-241. | |

| [19] | FARFÁN-CABRERA L I, GALLARDO-HERNÁNDEZ E A, deLa ROSA C S, et al. Micro-scale Abrasive Wear of Some Sealing Elastomers[J]. Wear, 2017, 376:1347-1355. |

| [20] | Da SILVA W M, COSTA H L, de MELLO J D B. Transitions in Abrasive Wear Mechanisms:Effect of the Superimposition of Interactions[J]. Wear, 2011, 271(5/6):977-986. |

| [21] | FLITNEY R. Seals and Sealing Handbook[M]. 6th ed. Amsterdam:Elsevier, 2014. |

| [22] | LI Shanshan, XIU Shichao, SONG Wanli, et al. Experimental Study of Surface Roughness on Improving the Tribological Performance of Sealing Pairs in Magnetorheological Damper[J]. Smart Materials and Structures, 2022, 31(7):075021. |

| [23] | JAMADAR M E H, DESAI R M, SAINI R S T, et al. Dynamic Analysis of a Quarter Car Model with Semi-active Seat Suspension Using a Novel Model for Magneto-rheological (MR) Damper[J]. Journal of Vibration Engineering & Technologies, 2021, 9(1):161-176. |

| [1] | 杨赫然1, 2, 张培杰1, 2, 孙兴伟1, 2, 潘飞1, 2, 刘寅1, 2. 利用改进卷积神经网络的螺杆砂带磨削表面粗糙度预测[J]. 中国机械工程, 2025, 36(02): 325-332. |

| [2] | 鄢威1, 3, 王欣怡2, 3, 张华3, 朱硕2, 3, 江志刚2, 3. 考虑切削能耗和表面质量的碳纤维增强树脂基复合材料加工工艺参数优化决策[J]. 中国机械工程, 2024, 35(10): 1834-1844. |

| [3] | 徐成宇, 张万一, 张天鸿, 朱永伟. 固结磨料小工具头修形抛光钛合金叶片试验研究[J]. 中国机械工程, 2024, 35(09): 1606-1612. |

| [4] | 靳淇超1, 2, 包虎子1, 李良万3, 汪文虎3, 张锦淇1, 叶子银1, 郭磊1. DD5缓进磨削表面粗糙度和硬化率对疲劳性能影响研究[J]. 中国机械工程, 2024, 35(08): 1472-1479. |

| [5] | 贾志新, 张凯悦, 王津. 聚晶金刚石的混铁粉电火花加工方法研究[J]. 中国机械工程, 2023, 34(22): 2684-2692. |

| [6] | 王明, 董海, 王柏何, 王峥, 王加威. 2.5D Cf/SiC刹车材料浮动磨削工艺试验研究[J]. 中国机械工程, 2023, 34(20): 2434-2441. |

| [7] | 韩锐, 李秀红, 王嘉明, 李文辉, 程思源, 杨胜强, . 水平强制振动光整加工对TC4钛合金表面完整性参数的影响[J]. 中国机械工程, 2023, 34(17): 2037-2047. |

| [8] | 田龙, 黄传真, 刘盾, 姚鹏, 刘含莲, 刘雪飞. 激光辅助水射流微铣削单晶β-Ga2O3衬底的实验研究[J]. 中国机械工程, 2023, 34(13): 1559-1567. |

| [9] | 傅远韬, 文东辉, 孔凡志, 淦作昆, 成志超, . 线性液动压抛光加工的流场特性研究[J]. 中国机械工程, 2023, 34(11): 1306-1314. |

| [10] | 鲁艳军, 关伟锋, 孙佳劲, 莫睿, 伍晓宇. 基于放电修锐的粗金刚石砂轮干式镜面磨削技术[J]. 中国机械工程, 2023, 34(09): 1052-1060. |

| [11] | 王栋, 林洪旭, 赵静雯, 乔瑞勇, 张君宇, 赵睿. 高速切向车铣对18CrNiMo7-6钢表面完整性的影响[J]. 中国机械工程, 2023, 34(07): 812-820. |

| [12] | 郝宇聪, 赵韡, 杨焘, 郭鹏, . 射流束切削时在边壁约束下的直径增大变形及加工表面质量研究[J]. 中国机械工程, 2022, 33(17): 2029-2037. |

| [13] | 马廉洁, 李红双. 脆性材料机械加工表面粗糙度模型的研究进展[J]. 中国机械工程, 2022, 33(07): 757-768. |

| [14] | 张晓博, 朱栋. 长窄型薄壁叶片的套料电解加工[J]. 中国机械工程, 2022, 33(07): 797-803,810. |

| [15] | 章玉强, 胡中伟, 朱泽朋, 崔长彩, 陈铭欣, 谢斌晖, 李瑞萍. 硬脆性材料用柔性磨具研磨的加工表面粗糙度建模[J]. 中国机械工程, 2022, 33(07): 834-841. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||