ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

China Mechanical Engineering ›› 2025, Vol. 36 ›› Issue (12): 2903-2910.DOI: 10.3969/j.issn.1004-132X.2025.12.012

Yuqin GUO( ), Hang YIN(

), Hang YIN( ), Dongjie YANG, Chenxi LIU, Fuzhu LI

), Dongjie YANG, Chenxi LIU, Fuzhu LI

Received:2025-02-09

Online:2025-12-25

Published:2025-12-31

Contact:

Hang YIN

通讯作者:

尹航

作者简介:郭玉琴,女,1974年生,教授。研究方向为轻量化板材制备工艺原理及质量控制。E-mail: guoyuqin@ujs.edu.com。

基金资助:CLC Number:

Yuqin GUO, Hang YIN, Dongjie YANG, Chenxi LIU, Fuzhu LI. A Design Method of Wide Blade Ultrasonic Sonotrodes for Both of End and Side Faces Working by Cooperating Frequency Offset Compensation with Stepwise Hierarchical Optimization[J]. China Mechanical Engineering, 2025, 36(12): 2903-2910.

郭玉琴, 尹航, 杨栋杰, 刘晨曦, 李富柱. 频率偏移补偿协同分步逐级优化的端/侧两面加工宽刃超声工具头设计方法[J]. 中国机械工程, 2025, 36(12): 2903-2910.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.cmemo.org.cn/EN/10.3969/j.issn.1004-132X.2025.12.012

| 振动模式 | 水平换能器 | 垂直换能器 | 质点振动轨迹 |

|---|---|---|---|

| 模式1 | 开 | 关 |  |

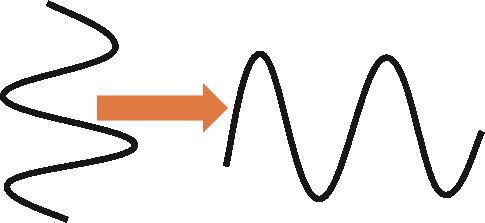

| 模式2 | 关 | 开 |  |

| 模式3 | 开  开 开 |  | |

| 模式4 | 开  开 开 |  | |

Tab.1 Operating modes provided by the ultrasonic vibration systemvibration system

| 振动模式 | 水平换能器 | 垂直换能器 | 质点振动轨迹 |

|---|---|---|---|

| 模式1 | 开 | 关 |  |

| 模式2 | 关 | 开 |  |

| 模式3 | 开  开 开 |  | |

| 模式4 | 开  开 开 |  | |

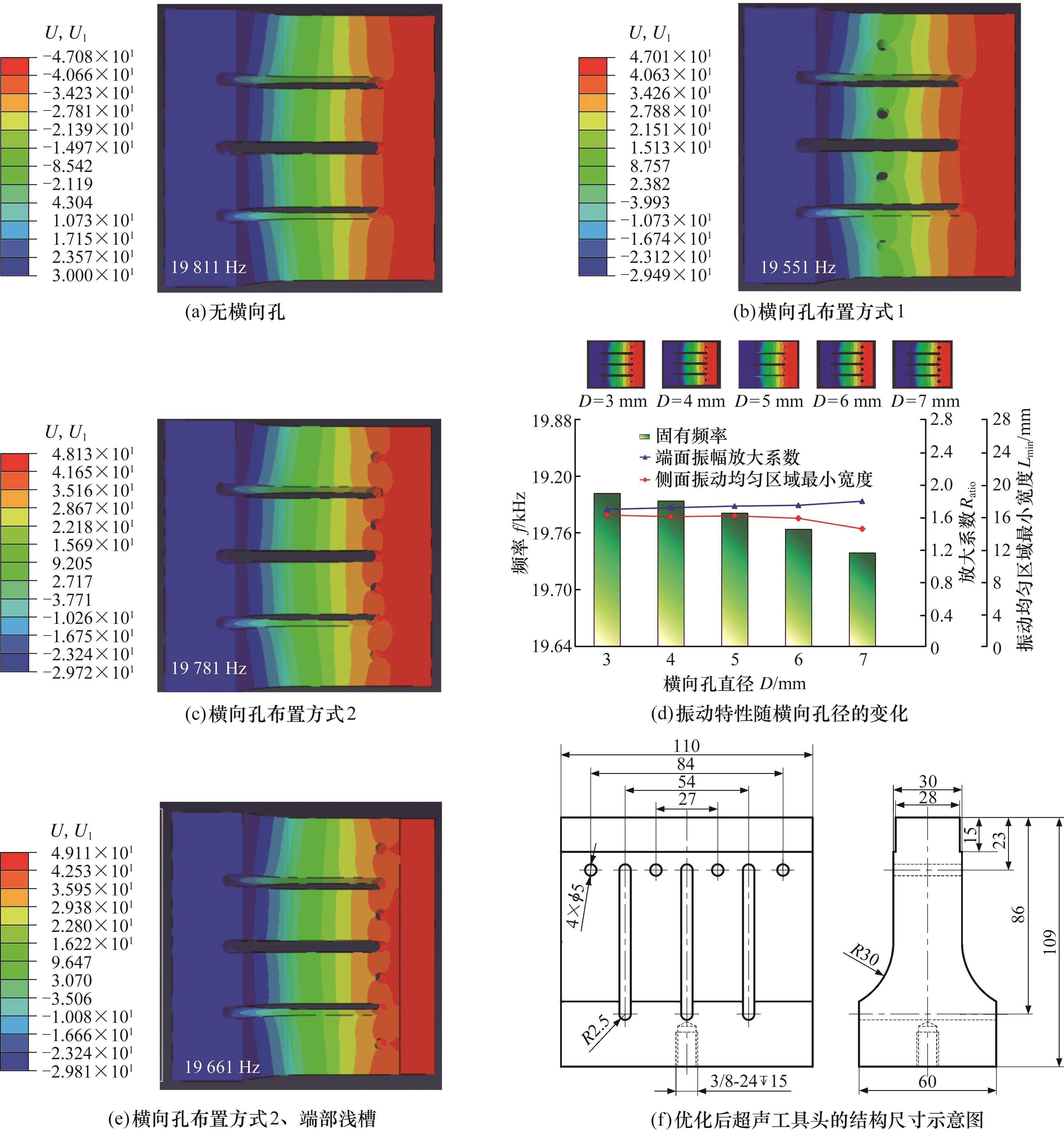

| 优化等级 | 方案 | 指标 | |

|---|---|---|---|

| 一级 | 槽数 | 0,1,2,3 | ①,②,③ |

| 槽宽/mm | 4,5,6,7,8 | ①,②,③ | |

| 槽长/mm | ①,②,③ | ||

| 槽端形状 | 圆弧端,直槽端 | ①,③ | |

| 二级 | 截面过渡圆弧 半径/mm | 0,15,30,45,60,75 | ①,④,⑤ |

| 三级 | 横向孔布置 | 中部布置,下部布置 | ①,④ |

| 横向孔直径/mm | 3,4,5,6,7 | ①,④,⑤ | |

| 浅槽布置 | 有,无 | ①,④ | |

Tab.2 Simulation program for the stepwise hierarchical optimization of sonotrode

| 优化等级 | 方案 | 指标 | |

|---|---|---|---|

| 一级 | 槽数 | 0,1,2,3 | ①,②,③ |

| 槽宽/mm | 4,5,6,7,8 | ①,②,③ | |

| 槽长/mm | ①,②,③ | ||

| 槽端形状 | 圆弧端,直槽端 | ①,③ | |

| 二级 | 截面过渡圆弧 半径/mm | 0,15,30,45,60,75 | ①,④,⑤ |

| 三级 | 横向孔布置 | 中部布置,下部布置 | ①,④ |

| 横向孔直径/mm | 3,4,5,6,7 | ①,④,⑤ | |

| 浅槽布置 | 有,无 | ①,④ | |

Fig.5 Change of the vibration characteristics of sonotrode with the configuration of transverse holes, shallow grooves, and its optimized structural dimensional diagram

对比 项目 | 固有 频率/Hz | 放大 系数 | 输出端面 振幅/μm | 侧面振动 区域最小 宽度/mm | 输入端面 均匀度/% | 输出端面均匀度/% |

|---|---|---|---|---|---|---|

优 化 前 | 17 282 | 1.15 | — | — | 39 | 85 |

优 化 后 | 19 961 | 1.67 | 24.1 | 15 | 92.80 | 96.90 |

Tab.3 Comparison of the vibration characteristics of sonotrode before and after optimization

对比 项目 | 固有 频率/Hz | 放大 系数 | 输出端面 振幅/μm | 侧面振动 区域最小 宽度/mm | 输入端面 均匀度/% | 输出端面均匀度/% |

|---|---|---|---|---|---|---|

优 化 前 | 17 282 | 1.15 | — | — | 39 | 85 |

优 化 后 | 19 961 | 1.67 | 24.1 | 15 | 92.80 | 96.90 |

| [1] | 张国庆,滕超逸.航空航天先进结构材料技术现状及发展趋势[J].航空材料学报,2024,44(2):1-12. |

| ZHANG Guoqing, TENG Chaoyi. Current Status and Development Ttrend of Advanced Structural Materials Technology in Aerospace field[J]. Journal of Aeronautical Materials,2024,44(2):1-12. | |

| [2] | 杜星炜,满雪辉.复合材料在船舶中的应用研究[J].纤维复合材料,2023,40(2):107-110. |

| DU Xingwei, MAN Xuehui. Study on the Application of Composites in Marine Ships[J]. Fiber Composites,2023,40(2):107-110. | |

| [3] | 秦铭泽,张伟涛,姬晓晨,等.复合材料在我国航空航天与轨道交通领域中的应用研究[J].热加工工艺,2024,53(6):6-9. |

| QIN Mingze, ZHANG Weitao, JI Xiaochen, et al. Application Research of Composite Materials in Aerospace and Rail Transit in China[J]. Hot Working Technology,2024,53(6):6-9. | |

| [4] | 王耀,曹佳华,杨超,等.超混杂纤维金属层板成形方法研究进展[J].精密成形工程,2023,15(3):19-35. |

| WANG Yao, CAO Jiahua, YANG Chao, et al. Research Progress in Forming Methods of Super Hybrid Fiber Metal Laminates[J]. Journal of Netshape Forming Engineering,2023,15(3):19-35. | |

| [5] | XIE Min, ZHAN Lihua, MA Bolin, et al. Classification of Fiber Metal Laminates (FMLs), Adhesion Theories and Methods for Improving Interfacial Adhesion: a Review[J].Thin-walled Structures,2024,198:111744. |

| [6] | 董传贺,孙晓宇,李旺鑫,等.基于超声调控浸润性的连续碳纤维复材3D打印研究[J].制造技术与机床,2024 (1):13-18. |

| DONG Chuanhe, SUN Xiaoyu, LI Wangxin, et al. Research on 3D Printing of Continuous Carbon Fiber Composite Materials Based on Ultrasonic Control of Infiltration[J]. Manufacturing Technology & Machine Tool,2024 (1):13-18. | |

| [7] | CHEN Yizhe, DAI Longyu, YANG Yusen,et.al. Improvement of Mechanical Properties and Mechanism Analysis of FMLs by Ultrasonic Vibration Assisted Hot Press Forming [J]. Fundamental Research, 2025 (In Press). |

| [8] | ZHOU Zhengwu, CHEN Chen. Research Advances in the Ultrasonic-assisting Adhesive Bonding[J].Journal of Manufacturing Processes,2024,110:134-160. |

| [9] | GUO Yuqin, XU Xingming, CHEN Zhanfu, et al. Deformation Mechanisms and Surface/Interface Characteristics of Titanium-based Thermoplastic FMLs Under Ultrasonic Impact Loading[J]. Ultrasonics,2024,138:107217. |

| [10] | CAO Yang, ZHU Yejun, LI Haonan, et al. Development and Performance of a Novel Ultrasonic Vibration Plate Sonotrode for Grinding[J]. Journal of Manufacturing Processes, 2020,57:174-186. |

| [11] | LI Shaochuan, XIAO Guijian, WANG Yingxin, et al. Multi-dimensional Ultrasonic-assisted Belt Grinding on the Surface Integrity of Inconel 718[J]. Journal of Manufacturing Processes, 2023,102:700-717. |

| [12] | MEHRAN A, BEHROOZ A. A New Design of Wide Blade Ultrasonic Horns Using Non-uniform Rational B-spline Shapes Slots[J]. Applied Acoustics, 2022,196:108871. |

| [13] | GU Guquan, WU Shujing, WANG Dazhong, et al. A Review of the Research on the Variation of Tool’s Motion Trajectory and Its Influence on the Formation Mechanism of Surface Quality in Ultrasonic Vibration Machining[J]. Journal of Manufacturing Processes, 2023, 107: 294-319. |

| [14] | 林基艳,孙姣夏,林书玉.大尺寸三维超声振动系统的智能优化设计[J].物理学报,2024,73(8):170-183. |

| LIN Jiyan, SUN Jiaoxia, LIN Yushu. Intelligent Optimization Design of Large-scale Three-dimensional Ultrasonic Vibration System[J]. Acta Physica Sinica,2024,73(8):170-183. |

| [1] | Zhibo CHEN, Guoping LI, Sitong XIANG, Yanding WEI. Dynamic Perception and Experimental Study of Tactile Texture Based on Ultrasonic Resonance Squeeze Film Effect [J]. China Mechanical Engineering, 2025, 36(11): 2574-2582. |

| [2] | ZHENG Jintao, MA Haoran, WANG Jin, LIU Guoliang. Experimental Study of Ultrasonic Vibration Assisted Turning Titanium Alloys with Nanofluid MQL [J]. China Mechanical Engineering, 2025, 36(04): 743-752,759. |

| [3] | ZHANG Chao1, REN Yinghui1, 2, YU Xiaolin1, LI Maojun2, YU Chengyang2, DU Xinliang1. Material Removal Mechanism of CFRP in Longitudinal-torsional Ultrasonic Milling Based on Mesoscopic Simulation Model [J]. China Mechanical Engineering, 2025, 36(04): 760-769,779. |

| [4] | SONG Pengfei1, 2, CAO Miaoyan1, 2, FU Min1, 2, CUI Yashuo1, 2, LI Yunfeng1, 2, LIU Zheng1, 2. Ultrasonic Vibration Softening Johnson-Cook Modeling and Validation of Thin Tube Curling Experiments [J]. China Mechanical Engineering, 2024, 35(12): 2106-2113,2121. |

| [5] | KANG Renke, LU Bingwei, CHEN Kailiang, LI Shengchao, DAI Jingbin, DONG Zhigang, BAO Yan. Study on Tearing of CFRP Thin Circular Tubes Machined by Ultrasonic Vibration Assisted Grinding [J]. China Mechanical Engineering, 2024, 35(03): 524-533,540. |

| [6] | TANG Yang, ZHANG Wudi, ZHANG Yulin, WANG Yuan, . Simulation and Experimental Study on Slip Bearing Performance and Pipe Wall Damage Characteristics of Pipeline Plugging Robots [J]. China Mechanical Engineering, 2023, 34(22): 2758-2771. |

| [7] | LIU Ying, CHEN Yue, ZHAO Xueli, YU Tongmin, ZHU Tieli, . Study on Properties of Ultrasonic-assisted Injection Molding of Carbon Fiber-reinforced Polypropylene Parts [J]. China Mechanical Engineering, 2023, 34(16): 1975-1981. |

| [8] | HAN Guangchao, YANG Jiakai, YE Zejiu, XU Linhong, ZHANG Haiou, YANG Haitao. Research on Longitudinal-Torsion Compound Ultrasonic Vibration Dry Milling Characteristics for AlMgSc Alloys Formed by Arc Micro-casting and Forging Additive Manufacturing [J]. China Mechanical Engineering, 2022, 33(24): 2971-2979,2989. |

| [9] | DONG Xianglong, ZHENG Lei, SONG Chunyang, LYU Dongming, XU Subai, WEI Wendong, QIN Peng. Finite Element Simulation and Experimental Study of Grinding Holes of SiC Ceramic Rotary Ultrasonic Vibration Trepanning Drilling [J]. China Mechanical Engineering, 2022, 33(17): 2107-2114. |

| [10] | SHEN Cheng;ZOU Ping;KANG Di;WANG Wenjie. Experimental Study on Ultrasonic Vibration Lens Assisted Laser Drilling [J]. China Mechanical Engineering, 2020, 31(21): 2542-2546. |

| [11] | LIU Ying;BI Jie;YU Tongmin. Salt Spray Aging Property of Molded Parts under Different Processing Parameters and Ultrasonic Vibrations [J]. China Mechanical Engineering, 2020, 31(09): 1115-1122. |

| [12] | ZOU YilanWEN DonghuiWANG YangyuXIAO YutingZOU Lei. Experimental Study and EDEM Numerical Simulation of Ultrasonic Vibration Finishing [J]. China Mechanical Engineering, 2020, 31(06): 647-654,661. |

| [13] | WANG Yuling, LIU Shanyong, ZHANG Xiangyu, LIU Yongwu, LI Rongchao. Experiments and Analyses of 3540Fe/CeO2 Coatings by Ultrasonic Vibration Assisted Laser Cladding [J]. China Mechanical Engineering, 2018, 29(21): 2600-2605. |

| [14] | LI Hui1;ZHENG Zhizhen1;WU Xiao1,2;LI Jianjun1. Rheological Forming Ability of Zr55Cu30Al10Ni5 Bulk Metallic Glasses under Ultrasonic Vibration Fields [J]. China Mechanical Engineering, 2017, 28(20): 2514-2519. |

| [15] | WANG Yan, WANG Shuai, LIU Jianguo, LI Delin. One Dimensional Oblique Ultrasonic Vibration Assisted Grinding for Rolling Bearing Steels and Experimental Validation [J]. China Mechanical Engineering, 2017, 28(09): 1021-1028. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||