ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

China Mechanical Engineering ›› 2025, Vol. 36 ›› Issue (8): 1668-1682.DOI: 10.3969/j.issn.1004-132X.2025.08.003

Longjun CHENG1,3( ), Gang LIU1(

), Gang LIU1( ), Lei CHEN1, Dongze LI2,3, Xiao XING1, Gan CUI1

), Lei CHEN1, Dongze LI2,3, Xiao XING1, Gan CUI1

Received:2024-10-18

Online:2025-08-25

Published:2025-09-18

Contact:

Gang LIU

程龙军1,3( ), 刘刚1(

), 刘刚1( ), 陈雷1, 李东泽2,3, 邢潇1, 崔淦1

), 陈雷1, 李东泽2,3, 邢潇1, 崔淦1

通讯作者:

刘刚

作者简介:程龙军,男,1989年生,高级工程师、博士研究生。研究方向为油气管道安全技术与装备等。E-mail:chenglj.qday@sinopec.com。基金资助:CLC Number:

Longjun CHENG, Gang LIU, Lei CHEN, Dongze LI, Xiao XING, Gan CUI. Research Progresses and Prospect of Key Technologies for Explosive Zone 0 Fans[J]. China Mechanical Engineering, 2025, 36(8): 1668-1682.

程龙军, 刘刚, 陈雷, 李东泽, 邢潇, 崔淦. 爆炸0区风机关键技术研究进展及展望[J]. 中国机械工程, 2025, 36(8): 1668-1682.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.cmemo.org.cn/EN/10.3969/j.issn.1004-132X.2025.08.003

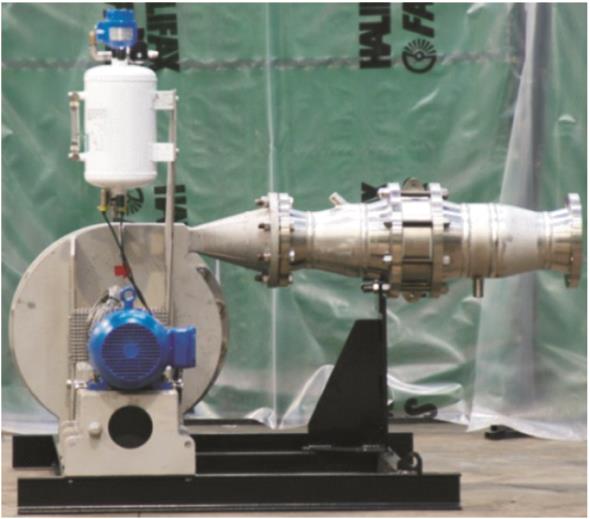

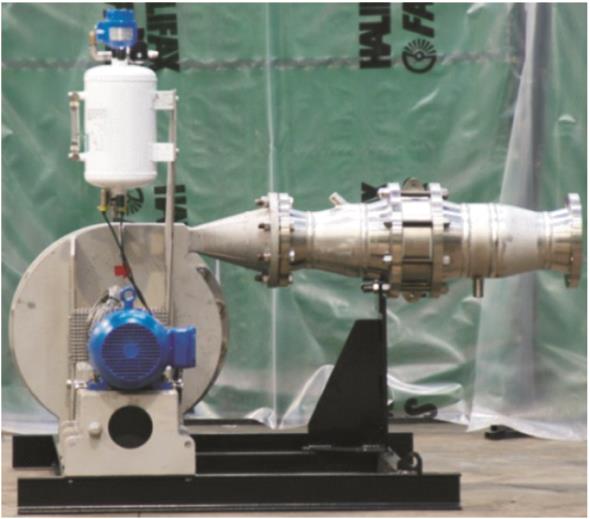

| 品牌 | 德国Fima | 英国Halifax | 瑞士Meidinger |

|---|---|---|---|

| 风机图 |  |  |  |

| 技术特点 | ①风机机壳与阻火器直连,具有最小的爆炸气量;②驱动型式获得防爆认证:皮带、联轴器、直驱;③转子动平衡提高操作安全性;④入口端静态密封,轴封采用涡形迷宫密封;⑤轴承配置温度监控 | ①轴封采用空气正压碳环气体密封;②出入口处安装阻火器,配置火焰捕捉器;③ 通过联轴器将电机与叶轮连接;④轴承箱配置振动监测 | ①阻火器配置温度传感器,检测异常工况和介质异常温度;②风机内部耐压设计;③集成火焰控制系统,通过温度传感器监控保证安全;④ 转速范围大,具有良好性能范围 |

Tab. 1 Technical characteristics of foreign explosion-proof fans in zone 0

| 品牌 | 德国Fima | 英国Halifax | 瑞士Meidinger |

|---|---|---|---|

| 风机图 |  |  |  |

| 技术特点 | ①风机机壳与阻火器直连,具有最小的爆炸气量;②驱动型式获得防爆认证:皮带、联轴器、直驱;③转子动平衡提高操作安全性;④入口端静态密封,轴封采用涡形迷宫密封;⑤轴承配置温度监控 | ①轴封采用空气正压碳环气体密封;②出入口处安装阻火器,配置火焰捕捉器;③ 通过联轴器将电机与叶轮连接;④轴承箱配置振动监测 | ①阻火器配置温度传感器,检测异常工况和介质异常温度;②风机内部耐压设计;③集成火焰控制系统,通过温度传感器监控保证安全;④ 转速范围大,具有良好性能范围 |

| [1] | 刘世达, 王海燕, 侯栓弟, 等. 我国石化储罐VOCs安全高效深度减排、回收和热氧化技术进展[J]. 化工进展, 2024, 43(4): 2063-2076. |

| LIU Shida, WANG Haiyan, HOU Shuandi, et al. Recent Advances in Safely Efficient Deep Emission Reduction, Recovery and Thermal Oxidation of VOCs from Petrochemical Storage Tanks in China[J]. Chemical Industry and Engineering Progress, 2024, 43(4): 2063-2076. | |

| [2] | 李长英, 陈明功, 盛楠, 等. 挥发性有机物处理技术的特点与发展[J]. 化工进展, 2016, 35(3): 917-925. |

| LI Changying, CHEN Minggong, SHENG Nan, et al. The Characteristics and Development of Volatile Organic Compounds Treatment Technology[J]. Chemical Industry and Engineering Progress, 2016, 35(3): 917-925. | |

| [3] | 李娜. 油气回收系统防爆通风机的点燃危险评估[J]. 安全、健康和环境, 2019, 19(10): 34-38. |

| LI Na. Ignition Hazard Assessment of Explosion-proof Fans for Oil Vapour Recovery Units[J]. Safety Health & Environment, 2019, 19(10): 34-38. | |

| [4] | 汤鹏, 梁峻, 王新华, 等. 非电气防爆安全点燃危险评定及其关键技术分析[J]. 电气防爆, 2016(2): 22-26. |

| TANG Peng, LIANG Jun, WANG Xinhua, et al. Analysis of Ignition Hazard Assessment and Its Key Technology of Non Electrie Explosion-proof Safety[J]. Electric Explosion Protection, 2016(2): 22-26. | |

| [5] | 陈国华, 林艺松, 王新华, 等. 基于组合赋权的防爆电气爆炸风险评估[J]. 天然气工业, 2015, 35(7): 103-109. |

| CHEN Guohua, LIN Yisong, WANG Xinhua, et al. Explosion Risk Evaluation on Explosion-proof Electric Apparatus Based on Combination Weighting[J]. Natural Gas Industry, 2015, 35(7): 103-109. | |

| [6] | 喻健良, 詹潇兵, 吕先舒, 等. 不同角度分叉管道内氢气-空气爆轰传播特性[J]. 爆炸与冲击, 2022, 42(12): 157-166. |

| YU Jianliang, ZHAN Xiaobing, Xianshu LYU, et al. Propagation Characteristics of Hydrogen-air Detonation in Bifurcated Tubes with Different Angles[J]. Explosion and Shock Waves, 2022, 42(12): 157-166. | |

| [7] | 鲍磊, 王鹏, 党茜, 等. 石化装置工业尺度管道爆轰传播实验研究[J]. 爆炸与冲击, 2021, 41(9): 145-151. |

| BAO Lei, WANG Peng, DANG Qian, et al. Experimental Study on Detonation Propagation in Industrial Scale Pipelines Used in Petrochemical Plants[J]. Explosion and Shock Waves, 2021, 41(9): 145-151. | |

| [8] | CHANG Xinyu, ZHANG Bo, NG H D, et al. The Effects of Pre-ignition Turbulence by Gas Jets on the Explosion Behavior of Methane-oxygen Mixtures[J]. Fuel, 2020, 277: 118190. |

| [9] | CHANG Xinyu, BAI Chunhua, ZHANG Bo, et al. The Effect of Ignition Delay Time on the Explosion Behavior in Non-uniform Hydrogen-air Mixtures[J]. International Journal of Hydrogen Energy, 2022, 47(16): 9810-9818. |

| [10] | CHENG Jun, ZHANG Bo, LIU Hong, et al. Experimental Study on the Effects of Different Fluidic Jets on the Acceleration of Deflagration Prior Its Transition to Detonation[J]. Aerospace Science and Technology, 2020, 106: 106203. |

| [11] | CHENG Jun, ZHANG Bo, LIU Hong, et al. The Precursor Shock Wave and Flame Propagation Enhancement by CO2 Injection in a Methane-oxygen Mixture[J]. Fuel, 2021, 283: 118917. |

| [12] | CHENG Jun, ZHANG Bo, DICK NG H, et al. Effects of Inert Gas Jet on the Transition from Deflagration to Detonation in a Stoichiometric Methane-oxygen Mixture[J]. Fuel, 2021, 285: 119237. |

| [13] | PENG Han, HUANG Yue, DEITERDING R, et al. Effects of Jet in Crossflow on Flame Acceleration and Deflagration to Detonation Transition in Methane⁃Oxygen Mixture[J]. Combustion and Flame, 2018, 198: 69-80. |

| [14] | 左哲, 姚志强, 高进东, 等. 受限空间内天然气爆炸反应过程模拟分析[J]. 天然气工业, 2015, 35(6): 131-137. |

| ZUO Zhe, YAO Zhiqiang, GAO Jindong, et al. Simulation Analysis of Natural Gas Explosion within Confined Space[J]. Natural Gas Industry, 2015, 35(6): 131-137. | |

| [15] | 杨石刚, 方秦, 张亚栋, 等. 非均匀混合可燃气云爆炸的数值计算方法[J]. 天然气工业, 2014, 34(6): 155-161. |

| YANG Shigang, FANG Qin, ZHANG Yadong, et al. A Numerical Method of Calculating the Consequence of Heterogeneous Mixed Vapor Cloud Explosion[J]. Natural Gas Industry, 2014, 34(6): 155-161. | |

| [16] | 严清华, 王淑兰, 李岳, 等. 大型球形密闭容器内可燃气体爆炸过程的数值模拟[J]. 天然气工业, 2004, 24(4): 101-103. |

| YAN Qinghua, WANG Shulan, LI Yue, et al. Numeral Simulation of Flammable Gas Explosions in Large Closed Spherical Vessels[J]. Natural Gas Industry, 2004, 24(4): 101-103. | |

| [17] | CAO Yong, LI Bin, GAO Kanghua. Pressure Characteristics during Vented Explosion of Ethylene-air Mixtures in a Square Vessel[J]. Energy, 2018, 151: 26-32. |

| [18] | MALLARD E, CHATELIER H, ANN L. Thermal Model for Flame Propagation[J]. Annales des Mines, 1883, 8:274-618. |

| [19] | URTIEW P A, OPPENHEIM A K. Experimental Observations of the Transition to Detonation in an Explosive Gas[J]. Proceedings of the Royal Society of London Series A, 1966, 295(1440): 13-28. |

| [20] | SHORT M, VOELKEL S J, KESSLER D A. Flame Acceleration in a Narrow Channel with Flow Compressibility and Diverging or Converging Walls[J]. Proceedings of the Combustion Institute, 2021, 38(2): 2205-2214. |

| [21] | 赵永耀. 可燃气体火焰加速及爆燃转爆轰的机理研究[D]. 北京: 北京理工大学, 2017. |

| ZHAO Yongyao. Investigation on the Mechanism of Flame Acceleration and Deflagration to Detonation Transition of Combustible Gases[D]. Beijing: Beijing Institute of Technology, 2017. | |

| [22] | BAUWENS C R L, BERGTHORSON J M, DOROFEEV S B. Experimental Investigation of Spherical-flame Acceleration in Lean Hydrogen-air Mixtures[J]. International Journal of Hydrogen Energy, 2017, 42(11): 7691-7697. |

| [23] | PHYLAKTOU H N, ANDREWS G E, HERATH P. Fast Flame Speeds and Rates of Pressure Rise in the Initial Period of Gas Explosions in Large L/D Cylindrical Enclosures[J]. Journal of Loss Prevention in the Process Industries, 1990, 3(4): 355-364. |

| [24] | 王金贵, 何伟杰, 张成名, 等. N2对甲烷-空气预混气体爆炸火焰传播稳定性的影响[J]. 福州大学学报(自然科学版), 2023, 51(4): 582-588. |

| WANG Jingui, HE Weijie, ZHANG Chengming, et al. Influence of N2 on the Flame Stability of Methane-air Premixed Gas[J]. Journal of Fuzhou University (Natural Science Edition), 2023, 51(4): 582-588. | |

| [25] | ZHAO Xinyu, WANG Jiabao, GAO Longkun, et al. Flame Acceleration and Onset of Detonation in Inhomogeneous Mixture of Hydrogen-air in an Obstructed Channel[J]. Aerospace Science and Technology, 2022, 130: 107944. |

| [26] | WANG Jiabao, ZHAO Xinyu, FAN Liangyi, et al. Effects of the Quantity and Arrangement of Reactive Jet Obstacles on Flame Acceleration and Transition to Detonation: a Numerical Study[J]. Aerospace Science and Technology, 2023, 137: 108269. |

| [27] | LI Min, LIU Dandan, SHEN Ting, et al. Effects of Obstacle Layout and Blockage Ratio on Flame Acceleration and DDT in Hydrogen-air Mixture in a Channel with an Array of Obstacles[J]. International Journal of Hydrogen Energy, 2022, 47(8): 5650-5662. |

| [28] | HISKEN H, ENSTAD G A, MIDDHA P, et al. Investigation of Concentration Effects on the Flame Acceleration in Vented Channels[J]. Journal of Loss Prevention in the Process Industries, 2015, 36: 447-459. |

| [29] | HAN Shixin, YU Minggao, YANG Xufeng, et al. Effects of Obstacle Position and Hydrogen Volume Fraction on Premixed Syngas-air Flame Acceleration[J]. International Journal of Hydrogen Energy, 2020, 45(53): 29518-29532. |

| [30] | ZHANG Ying, LI Qi, TANG Kaixuan, et al. Surface Inclination Effects on Heat Transfer during Flame Spread Acceleration Based on FireFOAM[J]. Case Studies in Thermal Engineering, 2022, 32: 101905. |

| [31] | ZHAO Mingbin, LIU Dandan, LI Min, et al. Effect of Wall Roughness on Flame Acceleration and Deflagration-to-detonation Transition in a Narrow Channel[J]. International Journal of Hydrogen Energy, 2024, 51: 880-893. |

| [32] | LI Tao, HUO Jiepeng, LI Xing, et al. Effects of Curvature on Flame Acceleration in Micro Channels[J]. Combustion and Flame, 2022, 242: 112168. |

| [33] | LI Tao, WANG Xiaohan, XU Baopeng, et al. An Efficient Approach to Achieve Flame Acceleration and Transition to Detonation[J]. Physics of Fluids, 2021, 33(5): 056103. |

| [34] | 程龙军. 爆炸0区防爆风机内部流场模拟及试验研究[J]. 流体机械, 2021, 49(5): 7-13. |

| CHENG Longjun. Simulation and Experimental Study of Flow Field of Explosion-proof Fan in Explosion Zone 0[J]. Fluid Machinery, 2021, 49(5): 7-13. | |

| [35] | HASSAN A S. Influence of the Volute Design Parameters on the Performance of a Centrifugal Compressor of an Aircraft Turbocharger[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2007, 221(5): 695-704. |

| [36] | HAGELSTEIN D, HILLEWAERT K, van den BRAEMBUSSCHE R A, et al. Experimental and Numerical Investigation of the Flow in a Centrifugal Compressor Volute[J]. Journal of Turbomachinery, 2000, 122(1): 22-31. |

| [37] | LU F A, QI D T, WANG X J, et al. A Numerical Optimization on the Vibroacoustics of a Centrifugal Fan Volute[J]. Journal of Sound and Vibration, 2012, 331(10): 2365-2385. |

| [38] | WORSTER R C. The Flow in Volutes and Its Effect on Centrifugal Pump Performance[J]. Proceedings of the Institution of Mechanical Engineers, 1963, 177(1): 843-875. |

| [39] | BALONI B D, PATHAK Y, CHANNIWALA S A. Centrifugal Blower Volute Optimization Based on Taguchi Method[J]. Computers & Fluids, 2015, 112: 72-78. |

| [40] | NILUGAL M L, KARANTH K V, MADHWESH N. Numerical Investigations on the Effect of Volute Casing Treatment for Performance Augmentation in a Centrifugal Fan[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2022, 236(6): 2791-2802. |

| [41] | SHEN Zhengjing, CHU Wuli, YAN Song, et al. Study of the Performance and Internal Flow in Centrifugal Pump with Grooved Volute Casing[J]. Modern Physics Letters B, 2020, 34(25): 2050268. |

| [42] | ASOMANI S N, YUAN Jianping, WANG Longyan, et al. Geometrical Effects on Performance and Inner Flow Characteristics of a Pump-as-turbine: a Review[J]. Advances in Mechanical Engineering, 2020, 12(4): 168781402091214. |

| [43] | HARIHARAN C, GOVARDHAN M. Improving Performance of an Industrial Centrifugal Blower with Parallel Wall Volutes[J]. Applied Thermal Engineering, 2016, 109: 53-64. |

| [44] | RUTSCHI K. The Effect of the Guide Apparatus on the Output and Efficiency of Centrifugal Pumps[J]. Schwiez Bauz,1961, 79:233–240. |

| [45] | AUNGIER R H. Centrifugal Compressors: a Strategy for Aerodynamic Design and Analysis[M].New York:ASME Press, 2000. |

| [46] | CHURCH A N. Centrifugal Pumps and Blowers[M]. Hemisphere Publishing Corporation, 1989:58-94. |

| [47] | ECK B. Fans:Design and Operation of Centrifugal, Axial-flow and Cross-flow Fans[M]. Oxford: Pergamon Press, 1973. |

| [48] | SHEPHERD D G. Principle of Turbomachinery[M]. New York: Macmillan Publishing Co., Inc., 1956. |

| [49] | STEPANOFF A J. Centrifugal & Axial Flow Pumps: Theory, Design and Application[M]. New York: Wiley, 1948. |

| [50] | STEPANOFF A J. Turbo Blowers: Theory, Design and Application of Centrifugal and Axial Flow Compressors and Fans[M]. New York: John Wiley & Sons, Inc., 1955. |

| [51] | TURTON R K. Principles of Turbomachinery[M]. New York, London: E. & F. N. Spon Ltd., 1984. |

| [52] | YAHYA S M. Turbine Compressors and Fans[M]. New Delhi: Tata Mcgraw Hill Publishing Company Limited, 2002. |

| [53] | AYDIN A, YIGIT C, ENGIN T, et al. Optimisation of a Mixed Flow Fan with NACA Profiled Blades Using Computational Fluid Dynamics[J]. Progress in Computational Fluid Dynamics, an International Journal, 2020, 20(5): 263. |

| [54] | LEE K J, PARK I W, BANG K S, et al. Optimal Design of a Plenum Fan with Three-dimensional Blades[J]. Applied Sciences, 2020, 10(10): 3460. |

| [55] | SAFARI M R, ANBARSOOZ M, NIAZMAND H. The Effects of the Return Channel Geometry on the Aerodynamic Performance of a Centrifugal Compressor: a Numerical Study[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2023, 237(5): 892-915. |

| [56] | ZHOU Shuiqing, ZHOU Huaxin, YANG Ke, et al. Research on Blade Design Method of Multi-blade Centrifugal Fan for Building Efficient Ventilation Based on Hicks-Henne Function[J]. Sustainable Energy Technologies and Assessments, 2021, 43: 100971. |

| [57] | LEE Y T, LIM H C. Performance Assessment of Various Fan Ribs Inside a Centrifugal Blower[J]. Energy, 2016, 94: 609-622. |

| [58] | LIU Shulian, GUO Yizhe, ZHANG Yuchi, et al. Effects of Tip Clearance and Impeller Eccentricity on the Aerodynamic Performance of Mixed Flow Fan[J]. Symmetry, 2023, 15(1): 201. |

| [59] | ZHANG Yifan, DOU Huashu. Effect of Blade Profile on the Performance of a Centrifugal Fan with Different Velocity Distribution Functions[J]. International Journal of Fluid Machinery and Systems, 2020, 13(3): 623-634. |

| [60] | 刘阳, 许子倩, 张义云, 等. S型仿生叶片对可逆多翼离心风机气动性能的影响[J]. 工程热物理学报, 2021, 42(11): 2841-2848. |

| LIU Yang, XU Ziqian, ZHANG Yiyun, et al. Effects of S-type Bionic Blade on Aerodynamic Performance of Reversible Multi-blade Centrifugal Fan[J]. Journal of Engineering Thermophysics, 2021, 42(11): 2841-2848. | |

| [61] | 王加浩, 龚东巧, 刘小民, 等. 采用仿鲤科鱼C型启动构型叶片的多翼离心风机气动性能研究[J]. 西安交通大学学报, 2022, 56(9): 57-68. |

| WANG Jiahao, GONG Dongqiao, LIU Xiaomin, et al. Aerodynamic Performance of Multi-blade Centrifugal Fan with Bionic Blades Inspired by C-type Start of Cyprinidae[J]. Journal of Xi’an Jiaotong University, 2022, 56(9): 57-68. | |

| [62] | 孟永哲, 许子倩, 刘小民. 多翼离心风机模化设计中叶轮-蜗壳的匹配性研究[J]. 风机技术, 2022, 64(3): 10-16. |

| MENG Yongzhe, XU Ziqian, LIU Xiaomin. Study on the Matching of Impeller and Volute in the Modeling Design of Multi-blade Centrifugal Fan[J]. Chinese Journal of Turbomachinery, 2022, 64(3): 10-16. | |

| [63] | 刘阳, 刘小民, 陈宗华, 等. 多翼离心风机分组优化设计对风机盘管整机气动性能的响应度研究[J]. 西安交通大学学报, 2022, 56(7): 156-167. |

| LIU Yang, LIU Xiaomin, CHEN Zonghua, et al. Responsiveness of Grouping Optimization Design of Multi-blade Centrifugal Fan to Aerodynamic Performance of Fan Coil Unit[J]. Journal of Xi’an Jiaotong University, 2022, 56(7): 156-167. | |

| [64] | MICHALSON A, AMENDE K L, JOHNSON E. Studying the Effects of Suction Chamber Intrusions and Housing Proximity on Backward Centrifugal Fan Performance Utilizing Computational Fluid Dynamics[J]. ASHRAE Transactions, 2022, 128: 236-243. |

| [65] | LIU Xue, LIU Jian, WANG Dong, et al. Experimental and Numerical Simulation Investigations of an Axial Flow Fan Performance in High-altitude Environments[J]. Energy, 2021, 234: 121281. |

| [66] | QIU Xiaozhang, YU Jianghong, YAO Qishui, et al. Reliability-based Analysis Method of Fluid Dynamics for Turbomachinery with Interval Distribution Parameters[J]. Engineering Optimization, 2021, 53(6): 919-940. |

| [67] | 蒋博彦, 肖千豪, 杨筱沛, 等. 多翼离心风机蜗壳小型化设计数值研究[J]. 机械工程学报, 2021, 57(9): 175-182. |

| JIANG Boyan, XIAO Qianhao, YANG Xiaopei, et al. Numerical Study on Downsizing Design of Multi-blade Centrifugal Fan Volute[J]. Journal of Mechanical Engineering, 2021, 57(9): 175-182. | |

| [68] | SONG Zhiliang, XIE Dacheng, LING yu, et al. Finite Element Analysis for Petiole’s Fracture of Mine-used Explosion-proof Axial Fan[J]. Applied Mechanics and Materials, 2014, 680: 228-232. |

| [69] | 曹海兰, 李阳, 乔世强. 离心通风机叶轮应力与振动分析[J]. 内燃机与配件, 2020(11): 76-78. |

| CAO Hailan, LI Yang, QIAO Shiqiang. Stress and Vibration Analysis of Centrifugal Fan Impeller[J]. Internal Combustion Engine & Parts, 2020(11): 76-78. | |

| [70] | SUN Yu, WANG Xiaoyu, DU Lin, et al. Effect of Acoustic Treatment on Fan Flutter Stability[J]. Journal of Fluids and Structures, 2020, 93: 102877. |

| [71] | FAN Chengwei, AMANKWA ADJEI R, WU Yadong, et al. Parametric Study on the Aerodynamic Performance of a Ducted-fan Rotor Using Free-form Method[J]. Aerospace Science and Technology, 2020, 101: 105842. |

| [72] | MOHAIDEEN M M. Optimization of Backward Curved Aerofoil Radial Fan Impeller Using Finite Element Modelling[J]. Procedia Engineering, 2012, 38: 1592-1598. |

| [73] | YE Xuemin, LI Pengmin, LI Chunxi, et al. Numerical Investigation of Blade Tip Grooving Effect on Performance and Dynamics of an Axial Flow Fan[J]. Energy, 2015, 82: 556-569. |

| [74] | LIU Rui, SUN Yu, NI Jun. Geometric Deformation Prediction of a Centrifugal Impeller Considering Welding Distortion and Fluid-structure Interaction[J]. Journal of Manufacturing Processes, 2023, 96: 80-98. |

| [75] | ZHANG Jiankun, LIU Haihu. Effect of Blade Tip Pattern on Blade Load and Vibration Characteristics of a Twin-stage Axial Flow Fan[J]. Journal of Mechanical Science and Technology, 2022, 36(7): 3487-3500. |

| [76] | ZHANG Lei, HE Ruiyang, WANG Xin, et al. Study on Static and Dynamic Characteristics of an Axial Fan with Abnormal Blade under Rotating Stall Conditions[J]. Energy, 2019, 170: 305-325. |

| [77] | ZHAO Ying, FENG Jianmei, ZHOU Qiang, et al. Blade Fracture Analysis of a Motor Cooling Fan in a High-speed Reciprocating Compressor Package[J]. Engineering Failure Analysis, 2018, 89: 88-99. |

| [78] | NAKANISHI Y, HONDA T, NAKASHIMA Y, et al. Shaft Seal for Separation of Water and Air with Low Frictional Torque[J]. Tribology International, 2016, 94: 437-445. |

| [79] | HU Songtao, HUANG Weifeng, SHI Xi, et al. Evolution of Bi-Gaussian Surface Parameters and Sealing Performance for a Gas Face Seal under a Low-speed Condition[J]. Tribology International, 2018, 120: 317-329. |

| [80] | XU Jing, PENG Xudong, BAI Shaoxian, et al. Experiment on Wear Behavior of High Pressure Gas Seal Faces[J]. Chinese Journal of Mechanical Engineering, 2014, 27(6): 1287-1293. |

| [81] | DINGUI K, BRUNETIÈRE N, BOUYER J, et al. Surface Texturing to Reduce Temperature in Mechanical Seals[J]. Tribology Online, 2020, 15(4): 222-229. |

| [82] | CHÁVEZ A, de SANTIAGO O. Experimental Measurements of the Thermo Elastic Behavior of a Dry Gas Seal Operating with Logarithmic Spiral Grooves of 11° and 15°[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2021, 235(9): 1807-1819. |

| [83] | VARNEY P, GREEN I. Impact Phenomena in a Noncontacting Mechanical Face Seal[J]. Journal of Tribology, 2017, 139(2): 022201. |

| [84] | LUO Yin, FAN Yakun, HAN Yuejiang, et al. Research on the Dynamic Characteristics of Mechanical Seal under Different Extrusion Fault Degrees[J]. Processes, 2020, 8(9): 1057. |

| [85] | HU Songtao, HUANG Weifeng, LIU Xiangfeng, et al. Influence Analysis of Secondary O-ring Seals in Dynamic Behavior of Spiral Groove Gas Face Seals[J]. Chinese Journal of Mechanical Engineering, 2016, 29(3): 507-514. |

| [86] | XUAN Haijun, ZHANG Na, LU Bin, et al. Investigation of High-speed Abrasion Behavior of an Abradable Seal Rubber in Aero-engine Fan Application[J]. Chinese Journal of Aeronautics, 2017, 30(4): 1615-1623. |

| [87] | LI Xinrui, FAN Xiaoqiang, LI Zhenggui, et al. Failure Mechanism of Magnetic Fluid Seal for Sealing Liquids[J]. Tribology International, 2023, 187: 108700. |

| [88] | HUANG T C, LIN C Y, LIAO K C. Sealing Performance Assessments of PTFE Rotary Lip Seals Based on the Elasto-hydrodynamic Analysis with the Modified Archard Wear Model[J]. Tribology International, 2022, 176: 107917. |

| [89] | SHIMADA K, KIMURA K, WATANABE H. A Study of Radiator Cooling Fan with Labyrinth Seal[J]. JSAE Review, 2003, 24(4): 431-439. |

| [90] | LI Guoqing, ZHANG Shen, KANG Zhong, et al. Leakage and Wear Characteristics of Carbon Seals for Aero-engines[J]. Chinese Journal of Aeronautics, 2022, 35(11): 389-400. |

| [91] | OUTIRBA B, HENDRICK P. Operating Life Assessment of a Carbon Fibre Brush Seal through Endurance Testing[J]. Tribology International, 2023, 179: 108076. |

| [92] | TENG Liming, JIANG Jinbo, PENG Xudong, et al. Influence of Surface Grooving Methods on Steady and Dynamic Performance of Spiral Groove Gas Face Seals[J]. Alexandria Engineering Journal, 2023, 64: 55-80. |

| [93] | PARMAR S, RAMANI V, UPADHYAY R V, et al. Two Stage Magnetic Fluid Vacuum Seal for Variable Radial Clearance[J]. Vacuum, 2020, 172: 109087. |

| [94] | HU Fengming, HE Qiang, HUANG Weifeng, et al. Face Grooves for State Monitoring in Dry Gas Seals[J]. Tribology International, 2023, 189: 108950. |

| [95] | 孙少辰. 波纹管道阻火器系统的阻爆特性研究[D]. 大连: 大连理工大学, 2018. |

| SUN Shaochen. Research of Explosion Resistant Characteristic in In-line Crimped-ribbon Flame Arrester[D]. Dalian: Dalian University of Technology, 2018. | |

| [96] | 黄名宗. 防爆柴油机排气阻火器流场分析及结构改进[D]. 太原: 中北大学, 2015. |

| HUANG Mingzong. Flow Field Analysis and Structure Improvement of flameproof Diesel Engine Flame Barrier[D]. Taiyuan: North University of China, 2015. | |

| [97] | 贺滕, 王维斌, 赵弘, 等. 基于FLUENT管内封堵器周围流场的数值模拟[J]. 油气储运, 2013, 32(6): 615-619. |

| HE Teng, WANG Weibin, ZHAO Hong, et al. Fluent-based Numerical Simulation of the Flow Field around the Plugging Tools[J]. Oil & Gas Storage and Transportation, 2013, 32(6): 615-619. | |

| [98] | SUN Shaochen, LIU Gang, LIU Junxuan, et al. Effect of Porosity and Element Thickness on Flame Quenching for In-line Crimped-ribbon Flame Arresters[J]. Journal of Loss Prevention in the Process Industries, 2017, 50: 221-228. |

| [99] | BAO Lei, WANG Peng, DANG Wenyi, et al. Experimental Study on Detonation Flame Penetrating through Flame Arrester[J]. Journal of Loss Prevention in the Process Industries, 2021, 72: 104529. |

| [100] | WANG Luqing, MA Honghao, SHEN Zhaowu. The Quenching of Propane Deflagrations by Crimped Ribbon Flame Arrestors[J]. Journal of Loss Prevention in the Process Industries, 2016, 43: 567-574. |

| [101] | HAMZAH N F, KASMANI R M, CHANDREN S, et al. Effect of Metal Coating on Physicochemical Properties of Ceramic Foam for Flame Suppression Application[J]. Ceramics International, 2023, 49(22): 36646-36658. |

| [102] | CHEN Jiayan, JIN Kaiqiang, DUAN Qiangling, et al. Experimental Study on the Competing Effect of Ceramic Pellets on Premixed Methane-air Flame Propagation in a Duct[J]. Journal of Loss Prevention in the Process Industries, 2021, 72: 104530. |

| [103] | YUAN Bihe, HE Yunlong, CHEN Xianfeng, et al. Flame and Shock Wave Evolution Characteristics of Methane Explosion in a Closed Horizontal Pipeline Filled with a Three-dimensional Mesh Porous Material[J]. Energy, 2022, 260: 125137. |

| [1] |

SUN Dong-Shu, HU Feng-Bin, QIN Da-Tong, LIU Zhen-Jun.

An Experimental Analysis on Thermal Stress Distributions in a Multiple Disc Wet Brake

[J]. J4, 201016, 21(16): 2006-2010.

|

| [2] | NIU Yanzhao1, LIU Hongwei1, SONG Yali2, ZHU Xianglong1, HUANG Jiamei2, KANG Renke1. Optimization and Experimental Study of Bolt Retreat Groove Rolling Wheels Based on Finite Element Simulation [J]. China Mechanical Engineering, 2025, 36(06): 1214-1221. |

| [3] | GUAN Jiaoyue1, GAO Yuan1, AI Yanting1, TIAN Jing1, YAO Yudong2. Thread Extension Stress Analysis of Bolts under Pre-tensioning Conditions [J]. China Mechanical Engineering, 2025, 36(05): 923-932. |

| [4] | RAO Yuan1, SUN Jianjun1, WEN Lan2. Research on Liquid Film Vaporization and Structural Optimization of End Faces for Diffuser Self-pumping Mechanical Seals [J]. China Mechanical Engineering, 2025, 36(05): 933-941,953. |

| [5] | DU Bing1, 2, LI Yang1, 2, LIU Fenghua1, 2, DONG Mingxin1, 2, WAN Yufan1, 2, ZHONG Qingshuai1, 2. Establishment and Influences of Critical Wrinkling Criterion of Sheet Metals Considering Thickness Stress [J]. China Mechanical Engineering, 2025, 36(05): 1074-1082. |

| [6] | GUO Feiyan1, ZHANG Yongliang2, LIU Jialiang1, ZHANG Hui2. Effects of Forced Positioning&Clamping on Geometric and Physical Assembly Performances for Composite Structures and Collaborative Guarantee Strategies [J]. China Mechanical Engineering, 2025, 36(04): 655-670. |

| [7] | ZHOU Jinhua1, 2, QI Qi1, 2, REN Junxue1, 2, ZHAN Mei1, 2. Inverse Solution for TC4 Residual Stress Gradient Distribution in Four-axis Milling with Tapered Ball-end Cutters [J]. China Mechanical Engineering, 2025, 36(04): 770-779. |

| [8] | LIU Yang1, WEN Zefeng1, WU Xingwen2, ZHOU Yabo1, TAO Gongquan1, ZHANG Zhenxian3, HOU Jianwen3, YI Zhi4. Fatigue Failure Study and Topology Optimization of Metro Vehicle Cowcatchers Based on Virtual Excitation Method [J]. China Mechanical Engineering, 2025, 36(04): 840-849. |

| [9] | XU Ping, LUO Jing, YU Yinghua, SHEN Jiaxing, LI Wenli. Study on Performance and Optimal Design of Friction Pairs of Textured Disk [J]. China Mechanical Engineering, 2024, 35(10): 1774-1782. |

| [10] | TIAN Tao1, 3, LI Wenhui2, 3, 4, WEN Xuejie1, 3, LI Xiuhong1, 3, YANG Shengqiang1, 3. DEM-FEM Coupled Simulation and Experimental Study of Residual Stresses in Horizontal Vibratory Finishing Processes [J]. China Mechanical Engineering, 2024, 35(09): 1667-1676. |

| [11] | DONG Zhibo1, LI Chengkun1, WANG Chengcheng1, HAN Fang1, ZHANG Zhihang1, TENG Junfei2, LYU Yanlong2. Study on Influence Rules of Residual Stress on Thermal Fatigue Life of GH3230 Laminate Welds [J]. China Mechanical Engineering, 2024, 35(06): 1097-1102. |

| [12] | ZENG Weihe, GOU Ligang, WANG Mingqing, WANG Lei, YU Ronggui. Fatigue Analysis and Experimental Study of Aluminum Alloy No-rivet Clinch Connections Based on Equivalent Structural Stress Method [J]. China Mechanical Engineering, 2024, 35(06): 1129-1139. |

| [13] | QIAN Ping, CHEN Chi, CHEN Wenhua, WU Shanqi, GUO Mingda. Accelerated Test Verification and Evaluation of Storage Reliability Statistical Model of Polyurethane Sealing Elements for Electrical Connectors [J]. China Mechanical Engineering, 2024, 35(05): 886-894. |

| [14] | ZHANG Jinyang, XU Weichun, WANG Xiaohan, JIANG Xiaohui, GAO Shan. Study on Influences of Milling Process Optimization on Residual Stress Distribution for Machining Nickel-based Superalloys [J]. China Mechanical Engineering, 2024, 35(04): 624-635. |

| [15] | YANG Yixiao, SUN Dan, LAN Kexin, ZHAO Huan, FENG Yuzhong, ZHANG Jieyi, . Experimental Study of Matching of Brush Seal Friction Pairs Based on Frictional Heating Effects [J]. China Mechanical Engineering, 2024, 35(04): 636-645,690. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||