ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (8): 1658-1667.DOI: 10.3969/j.issn.1004-132X.2025.08.002

收稿日期:2024-08-20

出版日期:2025-08-25

发布日期:2025-09-18

通讯作者:

刘怀举

作者简介:贾晨帆,男,1996年生,博士研究生。研究方向为齿轮传动智能数据库。基金资助:

Chenfan JIA, Huaiju LIU( ), Caichao ZHU, Taimin CHEN, Jinxiao CHEN

), Caichao ZHU, Taimin CHEN, Jinxiao CHEN

Received:2024-08-20

Online:2025-08-25

Published:2025-09-18

Contact:

Huaiju LIU

摘要:

开展了齿轮胶合承载能力试验,开发无线测试装置以获取齿轮本体温度数据集,并在此基础上提出了基于CatBoost的航空齿轮本体温度预测方法。此外,辨识了润滑油添加剂、热导率、扭矩、表面硬度、表面粗糙度、润滑油密度、润滑油黏度等参数对本体温度的贡献度,提出了考虑材料和油品参数的航空齿轮本体温度预测公式。结果表明,所提的公式对航空齿轮本体温度的预测误差在10%以内,为航空齿轮抗胶合设计提供了新思路。

中图分类号:

贾晨帆, 刘怀举, 朱才朝, 陈泰民, 陈进筱. 基于CatBoost的航空齿轮本体温度预测方法与验证研究[J]. 中国机械工程, 2025, 36(8): 1658-1667.

Chenfan JIA, Huaiju LIU, Caichao ZHU, Taimin CHEN, Jinxiao CHEN. An Aviation Gear Bulk Temperature Prediction Method and Verification Research Based on CatBoost[J]. China Mechanical Engineering, 2025, 36(8): 1658-1667.

| 材料类型 | 抗拉 强度 | 屈服 强度 | 伸长率 | 断面收缩率 |

|---|---|---|---|---|

| 12Cr2Ni4A | 1100~1296 | ≥940 | ≥15 | ≥59 |

| 18Cr2Ni4WA | ≥1180 | ≥835 | ≥10 | ≥45 |

| 16Cr3NiWMoVNbE | ≥1400 | ≥1020 | ≥14 | ≥62 |

| 15Cr14Co12Mo5Ni2 | ≥1900 | ≥1450 | ≥17 | ≥60 |

表1 试验齿轮钢力学性能

Tab.1 Mechanical properties of test gear steel

| 材料类型 | 抗拉 强度 | 屈服 强度 | 伸长率 | 断面收缩率 |

|---|---|---|---|---|

| 12Cr2Ni4A | 1100~1296 | ≥940 | ≥15 | ≥59 |

| 18Cr2Ni4WA | ≥1180 | ≥835 | ≥10 | ≥45 |

| 16Cr3NiWMoVNbE | ≥1400 | ≥1020 | ≥14 | ≥62 |

| 15Cr14Co12Mo5Ni2 | ≥1900 | ≥1450 | ≥17 | ≥60 |

| 材料类型 | 12Cr2Ni4A | 18Cr2Ni4WA | 16Cr3NiWMoVNbE | 15Cr14Co12Mo5Ni2 |

|---|---|---|---|---|

| 密度/(kg·m-3) | 7700 | 7910 | 7850 | 7980 |

| 弹性模量/ | 206 | 202 | 210 | 211 |

| 泊松比 | 0.30 | 0.27 | 0.29 | 0.31 |

| 热膨胀系数/10-6K | 10.0 | 12.4 | 11.5 | 11.3 |

| 热导率/(W·m-1·K-1) | 25.0 | 47.0 | 38.0 | 16.5 |

| 质量热容/(J·kg-1·K-1) | 0.460 | 0.460 | 0.450 | 0.453 |

表2 90 ℃下试验齿轮钢的热物理性能参数

Tab.2 Thermophysical performance parameters of test gear steel at 90 ℃

| 材料类型 | 12Cr2Ni4A | 18Cr2Ni4WA | 16Cr3NiWMoVNbE | 15Cr14Co12Mo5Ni2 |

|---|---|---|---|---|

| 密度/(kg·m-3) | 7700 | 7910 | 7850 | 7980 |

| 弹性模量/ | 206 | 202 | 210 | 211 |

| 泊松比 | 0.30 | 0.27 | 0.29 | 0.31 |

| 热膨胀系数/10-6K | 10.0 | 12.4 | 11.5 | 11.3 |

| 热导率/(W·m-1·K-1) | 25.0 | 47.0 | 38.0 | 16.5 |

| 质量热容/(J·kg-1·K-1) | 0.460 | 0.460 | 0.450 | 0.453 |

| 技术参数 | 数值/范围 |

|---|---|

| 电机转速/(r·min-1) | 1455/2910 |

| 主动轴扭矩(小齿轮)/(N·m) | 0~534.5 |

| 中心距/mm | 91.5 |

| 齿宽/mm | 0~30 |

| 模数/mm | 2~8 |

| 润滑油使用温度/℃ | 50~100 |

| 润滑油流量/(L·min-1) | 0.1~2.0 |

表3 标准FZG齿轮胶合试验机参数

Tab.3 Parameters of standard FZG gear scuffing test rig

| 技术参数 | 数值/范围 |

|---|---|

| 电机转速/(r·min-1) | 1455/2910 |

| 主动轴扭矩(小齿轮)/(N·m) | 0~534.5 |

| 中心距/mm | 91.5 |

| 齿宽/mm | 0~30 |

| 模数/mm | 2~8 |

| 润滑油使用温度/℃ | 50~100 |

| 润滑油流量/(L·min-1) | 0.1~2.0 |

| 参数名称 | 值/表达式 | |

|---|---|---|

| 轴中心距a/mm | 91.5 | |

| 有效齿宽b/mm | 20 | |

| 工作节圆直径/mm | 小轮dw1 | 73.2 |

| 大轮dw2 | 109.8 | |

| 顶圆直径/mm | 小轮da1 | 88.5 |

| 大轮da2 | 112.3 | |

| 模数m | 4.5 | |

| 齿数 | 小轮z1 | 16 |

| 大轮z2 | 24 | |

| 变位系数 | 小轮x1 | 0.8532 |

| 大轮x2 | -0.5 | |

| 压力角α/(°) | 20 | |

| 啮合角αw/(°) | 22.5 | |

| 节圆线速度vw/(m·s-1) | 8.3 | |

| 齿顶滑动率 | 小轮ξE1 | 0.86 |

| 大轮ξA2 | 0.34 | |

| 齿根滑动率 | 小轮ξA1 | -0.52 |

| 大轮ξE2 | -5.96 | |

| 赫兹接触应力pe/MPa | ||

表4 FZG-A胶合试验齿轮的几何参数

Tab.4 Geometric parameters of FZG-A scuffing test gear

| 参数名称 | 值/表达式 | |

|---|---|---|

| 轴中心距a/mm | 91.5 | |

| 有效齿宽b/mm | 20 | |

| 工作节圆直径/mm | 小轮dw1 | 73.2 |

| 大轮dw2 | 109.8 | |

| 顶圆直径/mm | 小轮da1 | 88.5 |

| 大轮da2 | 112.3 | |

| 模数m | 4.5 | |

| 齿数 | 小轮z1 | 16 |

| 大轮z2 | 24 | |

| 变位系数 | 小轮x1 | 0.8532 |

| 大轮x2 | -0.5 | |

| 压力角α/(°) | 20 | |

| 啮合角αw/(°) | 22.5 | |

| 节圆线速度vw/(m·s-1) | 8.3 | |

| 齿顶滑动率 | 小轮ξE1 | 0.86 |

| 大轮ξA2 | 0.34 | |

| 齿根滑动率 | 小轮ξA1 | -0.52 |

| 大轮ξE2 | -5.96 | |

| 赫兹接触应力pe/MPa | ||

| 牌号 | 555 | 4450 | 4010 | 4106 |

|---|---|---|---|---|

| 40 ℃运动黏度/(mm·s-2) | 26.50 | 61.00 | 13.34 | 25.79 |

| 100 ℃运动黏度/(mm·s-2) | 5.20 | 9.55 | 3.31 | 5.22 |

| 合成基油 | 聚酯合成油 | 聚α烯烃合成油 | 聚酯 合成油 | 聚酯 合成油 |

| 适用温度/℃ | -20~220 | -40~120 | -20~220 | -20~220 |

| 添加剂 | 极压抗磨剂、抗氧剂、抗泡剂 | 极压剂、抗氧剂、减 摩剂 | 抗氧、抗腐蚀、抗磨损 | 抗氧、抗腐蚀、抗磨损 |

表5 不同润滑油参数

Tab.5 Parameters of different lubricants

| 牌号 | 555 | 4450 | 4010 | 4106 |

|---|---|---|---|---|

| 40 ℃运动黏度/(mm·s-2) | 26.50 | 61.00 | 13.34 | 25.79 |

| 100 ℃运动黏度/(mm·s-2) | 5.20 | 9.55 | 3.31 | 5.22 |

| 合成基油 | 聚酯合成油 | 聚α烯烃合成油 | 聚酯 合成油 | 聚酯 合成油 |

| 适用温度/℃ | -20~220 | -40~120 | -20~220 | -20~220 |

| 添加剂 | 极压抗磨剂、抗氧剂、抗泡剂 | 极压剂、抗氧剂、减 摩剂 | 抗氧、抗腐蚀、抗磨损 | 抗氧、抗腐蚀、抗磨损 |

| 粗糙度Ra/μm | 表面硬度HV/MPa | 扭矩/(N·m) | 90 ℃油黏度/(mm·s-2) | 90 ℃油密度/(kg·m-3) | 润滑剂添加剂参数 | 热膨胀系数/K | 热导率/ (W·m-1·K-1) | 最大本体温度/℃ |

|---|---|---|---|---|---|---|---|---|

| 0.68 | 645 | 3.3 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 95.5 |

| 0.68 | 645 | 13.7 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 99.5 |

| 0.68 | 645 | 35.3 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 101.5 |

| 0.68 | 645 | 60.8 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 105.5 |

| 0.68 | 645 | 94.1 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 108.0 |

| 0.68 | 645 | 135.5 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 112.5 |

| …… | ||||||||

| 0.50 | 738 | 183.4 | 6.35 | 946 | 0.0 | 1.15 | 38.0 | 134.0 |

| 0.42 | 678 | 183.4 | 10.09 | 895 | 0.5 | 1.24 | 47.0 | 124.5 |

| 0.42 | 678 | 239.3 | 10.09 | 895 | 0.5 | 1.24 | 47.0 | 136.0 |

| 0.42 | 678 | 302.0 | 10.09 | 895 | 0.5 | 1.24 | 47.0 | 141.0 |

| 0.46 | 820 | 35.3 | 3.91 | 910 | 0.0 | 1.13 | 16.5 | 102.0 |

| 0.46 | 820 | 94.1 | 3.91 | 910 | 0.0 | 1.13 | 16.5 | 108.0 |

| 0.46 | 820 | 302 | 3.914 | 910 | 0.0 | 1.13 | 16.5 | 148.0 |

表6 航空齿轮的本体温度测试数据

Tab.6 Bulk temperature test data of aviation gears

| 粗糙度Ra/μm | 表面硬度HV/MPa | 扭矩/(N·m) | 90 ℃油黏度/(mm·s-2) | 90 ℃油密度/(kg·m-3) | 润滑剂添加剂参数 | 热膨胀系数/K | 热导率/ (W·m-1·K-1) | 最大本体温度/℃ |

|---|---|---|---|---|---|---|---|---|

| 0.68 | 645 | 3.3 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 95.5 |

| 0.68 | 645 | 13.7 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 99.5 |

| 0.68 | 645 | 35.3 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 101.5 |

| 0.68 | 645 | 60.8 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 105.5 |

| 0.68 | 645 | 94.1 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 108.0 |

| 0.68 | 645 | 135.5 | 10.09 | 895 | 0.5 | 1.00 | 25.0 | 112.5 |

| …… | ||||||||

| 0.50 | 738 | 183.4 | 6.35 | 946 | 0.0 | 1.15 | 38.0 | 134.0 |

| 0.42 | 678 | 183.4 | 10.09 | 895 | 0.5 | 1.24 | 47.0 | 124.5 |

| 0.42 | 678 | 239.3 | 10.09 | 895 | 0.5 | 1.24 | 47.0 | 136.0 |

| 0.42 | 678 | 302.0 | 10.09 | 895 | 0.5 | 1.24 | 47.0 | 141.0 |

| 0.46 | 820 | 35.3 | 3.91 | 910 | 0.0 | 1.13 | 16.5 | 102.0 |

| 0.46 | 820 | 94.1 | 3.91 | 910 | 0.0 | 1.13 | 16.5 | 108.0 |

| 0.46 | 820 | 302 | 3.914 | 910 | 0.0 | 1.13 | 16.5 | 148.0 |

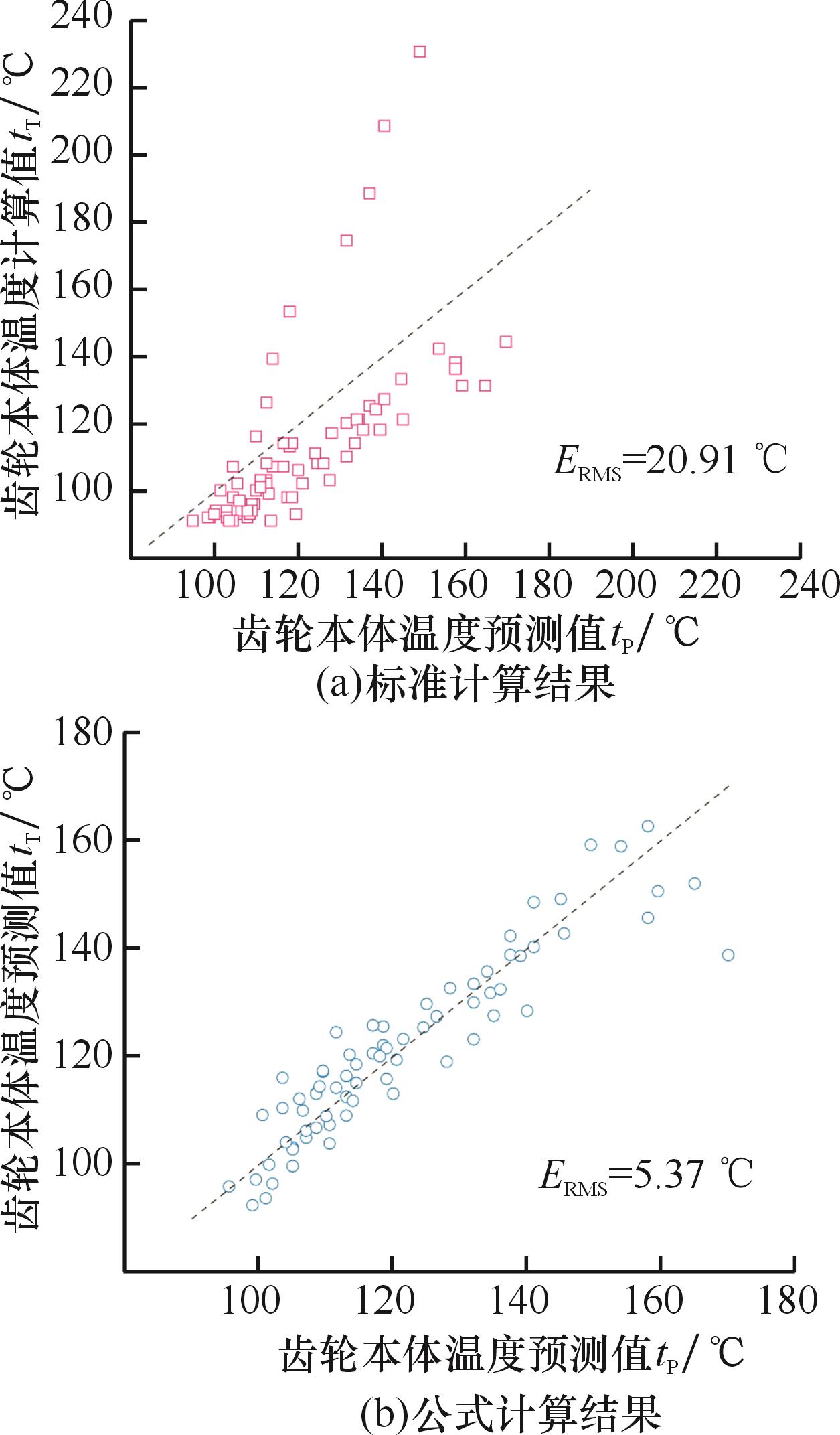

图10 齿轮本体温度公式与GB/Z 6413.1-2003标准计算结果对比

Fig.10 Comparison between the calculation results of the gear bulk temperature formula and the GB/Z 6413.1-2003 standard

| [1] | LU Zehua, CHEN Yiming, LIU Huaiju, et al. A High-power-density Design Method for Polymer Gear Systems via an Adaptive Non-dominated Sorting Genetic Algorithm III and Surrogate Sub-models[J]. Materials & Design, 2024, 240: 112875. |

| [2] | 吴吉展, 魏沛堂, 刘怀举, 等. 航空齿轮钢表面完整性与滚动接触疲劳性能关联规律研究[J]. 机械工程学报, 2024, 60(4): 284-295. |

| WU Jizhan, WEI Peitang, LIU Huaiju, et al. Study on the Correlation between Surface Integrity and Rolling Contact Fatigue Performance of Aviation Gear Steel[J]. Journal of Mechanical Engineering, 2024, 60(4): 284-295. | |

| [3] | WU Jizhan, WEI Peitang, ZHU Caichao, et al. Development and Application of High Strength Gears[J]. The International Journal of Advanced Manufacturing Technology, 2024, 132(7): 3123-3148. |

| [4] | WU Jizhan, WEI Peitang, LIU Guoqiang, et al. A Comprehensive Evaluation of DLC Coating on Gear Bending Fatigue, Contact Fatigue, and Scuffing Performance[J]. Wear, 2024, 536/537: 205177. |

| [5] | LU Zehua, LIU Chang, LIAO Changjun, et al. Conceptual Design and Optimization of Polymer Gear System for Low-thrust Turbofan Aeroengine Accessory Transmission[J]. Journal of Computational Design and Engineering, 2023, 11(1): 212-229. |

| [6] | 吴吉展, 魏沛堂, 吴少杰, 等. 航空齿轮钢滚动接触疲劳性能预测与表面完整性优化[J]. 机械工程学报, 2024, 60(8): 81-93. |

| WU Jizhan, WEI Peitang, WU Shaojie, et al. Rolling Contact Fatigue Performance Prediction and Surface Integrity Optimization of Aviation Gear Steel[J]. Journal of Mechanical Engineering, 2024, 60(8): 81-93. | |

| [7] | RIGGS M R, MURTHY N K, BERKEBILE S P. Scuffing Resistance and Starved Lubrication Behavior in Helicopter Gear Contacts: Dependence on Material, Surface Finish, and Novel Lubricants[J]. Tribology Transactions, 2017, 60(5): 932-941. |

| [8] | 李纪强, 朱博强, 刘忠明, 等. 齿轮传动微点蚀与热胶合竞争性失效机制研究[J]. 摩擦学学报, 2021, 41(5): 636-646. |

| LI Jiqiang, ZHU Boqiang, LIU Zhongming, et al. Competitive Failure Mechanism of Micro-Pitting and Thermal-scuffing in Gear Transmission[J]. Tribology, 2021, 41(5): 636-646. | |

| [9] | LUO Biao, LI Wei. Influence Factors on Bulk Temperature Field of Gear[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2017, 231(8): 953-964. |

| [10] | PENG Jie, LIU Shaojun, HU Xiaozhou. The Bulk Temperature Analysis of the Involute Spur Gear Based on Parameterized Modeling of APDL[C]∥Proceedings of the 2013 Fifth International Conference on Measuring Technology and Mechatronics Automation. ACM, 2013: 1146-1149. |

| [11] | CASTRO J, SEABRA J. Global and Local Analysis of Gear Scuffing Tests Using a Mixed Film Lubrication Model[J]. Tribology International, 2008, 41(4): 244-255. |

| [12] | CHEN Taimin, ZHU Caichao, LIU Huaiju, et al. Simulation and Experiment of Carburized Gear Scuffing under Oil Jet Lubrication[J]. Engineering Failure Analysis, 2022, 139: 106406. |

| [13] | JIANG Q Y, BARBER G C. Experimental Determination of Bulk Temperature and Critical Temperature in Scuffing Resistance Evaluation of Gears[J]. Tribology Transactions, 2000, 43(1): 21-26. |

| [14] | CHEN Jinxiao, ZHU Caichao, WEI Peitang, et al. Experimental Study on High-speed Aviation Gear Scuffing Based on Tooth Profile and Surface Treatment Improvements[J]. Tribology Transactions, 2024, 67(2): 280-293. |

| [15] | LI Yang, WEI Peitang, ZHAO Xinhao, et al. A Novel Approach of Shot Peening Process Parameters Prediction with Missing Surface Integrity Data Based on Imputation Method[J]. The International Journal of Advanced Manufacturing Technology, 2023, 127(1): 81-92. |

| [16] | LI Yang, WEI Peitang, XIANG Ge, et al. Gear Contact Fatigue Life Prediction Based on Transfer Learning[J]. International Journal of Fatigue, 2023, 173: 107686. |

| [17] | LIU Huaiju, LI Yang, LU Zehua, et al. A Unified Estimation Method for Gear Fatigue P-S-N Curves and Fatigue Limits Based on Ensemble Learning and Data Augmentation[J]. Engineering Fracture Mechanics, 2024, 298: 109941. |

| [18] | ZHANG Xiuhua, WEI Peitang, PARKER R G, et al. Study on the Relation between Surface Integrity and Contact Fatigue of Carburized Gears[J]. International Journal of Fatigue, 2022, 165: 107203. |

| [19] | LI Yang, LIU Huaiju, CHEN Yiming, et al. Probabilistic Gear Fatigue Life Prediction Based on Physics-informed Transformer[J]. Expert Systems with Applications, 2024, 249: 123882. |

| [20] | .齿轮FZG试验程序第1部分:油品的相对胶合承载能力—FZG试验方法A/8.3/90 [S]. 北京: 中国标准出版社, 2003. |

| . Gear-FZG Test Procedures- Part 1:FZG Test Method A/8.3/90 for Relative Scuffing Load-Carrying of Oils [S]. Beijing: Standards Press of China, 2003. | |

| [21] | .齿轮胶合承载能力试验方法 [S]. 北京: 中国标准出版社, 2003. |

| . Test Method for Scuffing Load Capacity of Gears [S]. Beijing: Standards Press of China, 2022. | |

| [22] | 罗维平, 周博, 陈军, 等. 基于Pt100的低温真空冷冻干燥机温度测量系统[J]. 现代电子技术, 2021, 44(18): 27-32. |

| LUO Weiping, ZHOU Bo, CHEN Jun, et al. Pt100-based Temperature Measurement System for Low Temperature Vacuum Freeze Dryer[J]. Modern Electronics Technique, 2021, 44(18): 27-32. | |

| [23] | COHEN I, HUANG Yiteng, CHEN Jingdong, et al. Noise Reduction in Speech Processing[M]. Berlin, Heidelberg: Springer, 2009 |

| [24] | SAMMIL S, SRIDHARAN M. Employing Ensemble Machine Learning Techniques for Predicting the Thermohydraulic Performance of Double Pipe Heat Exchanger with and without Turbulators[J]. Thermal Science and Engineering Progress, 2024, 47: 102337. |

| [25] | LI Shaojie, LIU Chun, ZHAO Jing, et al. Multiscale Deep Features and Empirical Features Fusion-based Gearbox Fault Diagnosis[C]∥2022 China Automation Congress (CAC). Xiamen, 2022: 54-59. |

| [26] | NAJM S M, TRZEPIECIŃSKI T, KOWALIK M. Modelling and Parameter Identification of Coefficient of Friction for Deep-drawing Quality Steel Sheets Using the CatBoost Machine Learning Algorithm and Neural Networks[J]. The International Journal of Advanced Manufacturing Technology, 2023, 124(7): 2229-2259. |

| [27] | CHENG Ganlin, XIANG Chong, GUO Fei, et al. Prediction of the Tribological Properties of a Polymer Surface in a Wide Temperature Range Using Machine Learning Algorithm Based on Friction Noise[J]. Tribology International, 2023, 180: 108213. |

| [28] | IBRAHEM AHMED OSMAN A, NAJAH AHMED A, CHOW M F, et al. Extreme Gradient Boosting (XGBoost) Model to Predict the Groundwater Levels in Selangor Malaysia[J]. Ain Shams Engineering Journal, 2021, 12(2): 1545-1556. |

| [29] | JIA Chenfan, WEI Peitang, LU Zehua, et al. A Novel Prediction Approach of Polymer Gear Contact Fatigue Based on a WGAN-XGBoost Model[J]. Fatigue & Fracture of Engineering Materials & Structures, 2023, 46(6): 2272-2283. |

| [30] | . 圆柱齿轮、锥齿轮和准双曲面齿轮 胶合承载能力计算方法 第1部分:闪温法 [S]. 北京: 中国标准出版社, 2003. |

| GB/Z 6413.1—2003. Calculation of Scuffing Load Capacity of Cylindrical, Bevel and Hypoid Gears- Part 1: Flash Temperature Method, 2003. | |

| [31] | SUN Xingyue, ZHOU Kun, SHI Shouwen, et al. A New Cyclical Generative Adversarial Network Based Data Augmentation Method for Multiaxial Fatigue Life Prediction[J]. International Journal of Fatigue, 2022, 162: 106996. |

| [1] | 郭飞燕1, 张辉2, 宋长杰1, 张硕1. 机理与数据融合驱动的复杂航空复材部件关键装配误差元素辨识方法[J]. 中国机械工程, 2025, 36(07): 1530-1543. |

| [2] | 赵培瑞1, 邓超1, 朱波1, 闫文斌1, 梁敏2, 谌敏2. 基于多元动因驱动的中药制药车间动态调度建模与优化[J]. 中国机械工程, 2025, 36(06): 1247-1260,1299. |

| [3] | 肖刚, 顾海瑞, 董锦锦, 王琪冰, 陆佳炜. 仿真数据驱动的长期服役电梯导轨故障迁移诊断方法[J]. 中国机械工程, 2024, 35(01): 125-135. |

| [4] | 张炜, 侯亮. 云平台数据驱动的产品与供应商资源主从协同优化[J]. 中国机械工程, 2021, 32(09): 1061-1072. |

| [5] | 李聪波;尹誉先;肖溱鸽;龙云;赵希坤. 数据驱动下基于元动作的数控车削能耗预测方法[J]. 中国机械工程, 2020, 31(21): 2601-2611. |

| [6] | 姜少飞;邬天骥;彭翔;李吉泉;李治;孙涛. 基于XGBoost特征提取的数据驱动故障诊断方法[J]. 中国机械工程, 2020, 31(10): 1232-1239. |

| [7] | 吴扬东, 张太华, 刘丹, 王宜全. [数据驱动的产品设计]复杂产品设计方案的数据驱动多属性优化决策[J]. 中国机械工程, 2020, 31(07): 865-870. |

| [8] | 李浩, 王昊琪, 程颖, 陶飞, 郝兵, 王新昌, 纪杨建, 宋文燕, 杜文辽, 文笑雨, 巩晓赟, 李客, 张映锋, 罗国富, 李奇峰. [数据驱动的智能服务]数据驱动的复杂产品智能服务技术与应用[J]. 中国机械工程, 2020, 31(07): 757-772. |

| [9] | 刘银华, 孙芮, 吴欢. [质量优化]基于车身尺寸数据流潜结构建模的装配质量预测控制[J]. 中国机械工程, 2019, 30(02): 237-243. |

| [10] | 杨振良, 汪俊亮, 张洁, 蒋小康. [质量优化]数据驱动的晶圆图缺陷模式识别方法[J]. 中国机械工程, 2019, 30(02): 230-236. |

| [11] | 高贵兵, 岳文辉, 王峰. [设备健康管理]基于CPS方法与脆弱性评估的制造系统健康状态智能诊断[J]. 中国机械工程, 2019, 30(02): 212-219. |

| [12] | 战洪飞, 邬益男, 张凡, 王程强. [制造服务]面向业务问题求解的模块化知识服务[J]. 中国机械工程, 2018, 29(20): 2395-2400. |

| [13] | 袁广超;鲍劲松;郑小虎;张洁. 基于CNC实时监测数据驱动方法的钛合金高速铣削刀具寿命预测[J]. 中国机械工程, 2018, 29(04): 457-462,470. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||