ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2026, Vol. 37 ›› Issue (1): 30-39.DOI: 10.3969/j.issn.1004-132X.2026.01.004

收稿日期:2025-05-27

出版日期:2026-01-25

发布日期:2026-02-05

通讯作者:

范雪

作者简介:余植敏,女,2002年生,硕士研究生。研究方向为纳米结构碳膜的制造及摩擦学特性、透射电镜原位摩擦下的碳膜摩擦机理。E-mail:2510095068@mails.szu.edu.cn基金资助:

YU Zhimin( ), CHEN Lei, FAN Xue(

), CHEN Lei, FAN Xue( )

)

Received:2025-05-27

Online:2026-01-25

Published:2026-02-05

Contact:

FAN Xue

摘要:

在SiO2基体上分别制备了纳米结构(非晶及石墨烯纳晶)碳膜,利用自主设计的多物理场耦合往复式摩擦学实验装置,研究了不同纳米结构的碳膜在温度电场耦合作用下的摩擦学特性。室温下,纳米结构碳膜摩擦因数的主要影响因素为电场;摩擦副温度为200 ℃时,纳米结构碳膜摩擦因数的主要影响因素为温度。温度电场耦合作用下,非晶碳膜的纳米结构向纳晶结构转化,摩擦因数减小;石墨烯纳晶碳膜结构稳定,但碳膜磨损加剧导致摩擦因数波动较大。

中图分类号:

余植敏, 陈磊, 范雪. 温度电场耦合下纳米结构碳膜的摩擦学特性及机理[J]. 中国机械工程, 2026, 37(1): 30-39.

YU Zhimin, CHEN Lei, FAN Xue. Tribological Properties and Mechanism of Nanostructured Carbon Films under Coupling Effect of Temperature and Electric Field[J]. China Mechanical Engineering, 2026, 37(1): 30-39.

| 参数 | 数值 | 参数 | 数值 | |

|---|---|---|---|---|

| 基片材料 | P型SiO2 | 基片尺寸/mm | 25×25 | |

| 工作气体 | 氩气 | 工作气压/Pa | 0.07 | |

| 靶材偏压/V | 基片偏压/V | |||

线圈 电流/A | 左 | 32 | 微波功率/W | 350 |

| 中 | 34 | |||

| 右 | 0 | 沉积时间/ min | 50 | |

表1 发散式离子照射纳米碳膜的制备参数

Tab.1 Preparation parameters of nanostructured carbon films by divergent ion irradiation

| 参数 | 数值 | 参数 | 数值 | |

|---|---|---|---|---|

| 基片材料 | P型SiO2 | 基片尺寸/mm | 25×25 | |

| 工作气体 | 氩气 | 工作气压/Pa | 0.07 | |

| 靶材偏压/V | 基片偏压/V | |||

线圈 电流/A | 左 | 32 | 微波功率/W | 350 |

| 中 | 34 | |||

| 右 | 0 | 沉积时间/ min | 50 | |

| 参数 | 数值 | 参数 | 数值 | |

|---|---|---|---|---|

| 基片材料 | P型SiO2 | 基片尺寸/mm | 25×25 | |

| 工作气体 | 氩气 | 工作气压/Pa | 0.07 | |

| 靶材偏压/V | 基片偏压/V | 50 | ||

线圈 电流/A | 左 | 40 | 微波功率/W | 256 |

| 中 | 40 | |||

| 右 | 48 | 沉积时间/min | 25 | |

表2 封闭式电子照射纳米碳膜制备参数

Tab.2 Preparation parameters of nanostructured carbon films by closed electron irradiation

| 参数 | 数值 | 参数 | 数值 | |

|---|---|---|---|---|

| 基片材料 | P型SiO2 | 基片尺寸/mm | 25×25 | |

| 工作气体 | 氩气 | 工作气压/Pa | 0.07 | |

| 靶材偏压/V | 基片偏压/V | 50 | ||

线圈 电流/A | 左 | 40 | 微波功率/W | 256 |

| 中 | 40 | |||

| 右 | 48 | 沉积时间/min | 25 | |

| 基片偏压/V | 薄膜厚度/nm | 方块电阻/ (kΩ/sq) | 电阻率/ (10 |

|---|---|---|---|

| 115 | 1.61 | 1.85 | |

| 50 | 115 | 0.72 | 0.83 |

表3 不同纳米结构碳膜方块电阻的测试结果

Tab.3 Test results of sheet resistance for different nanostructured carbon films

| 基片偏压/V | 薄膜厚度/nm | 方块电阻/ (kΩ/sq) | 电阻率/ (10 |

|---|---|---|---|

| 115 | 1.61 | 1.85 | |

| 50 | 115 | 0.72 | 0.83 |

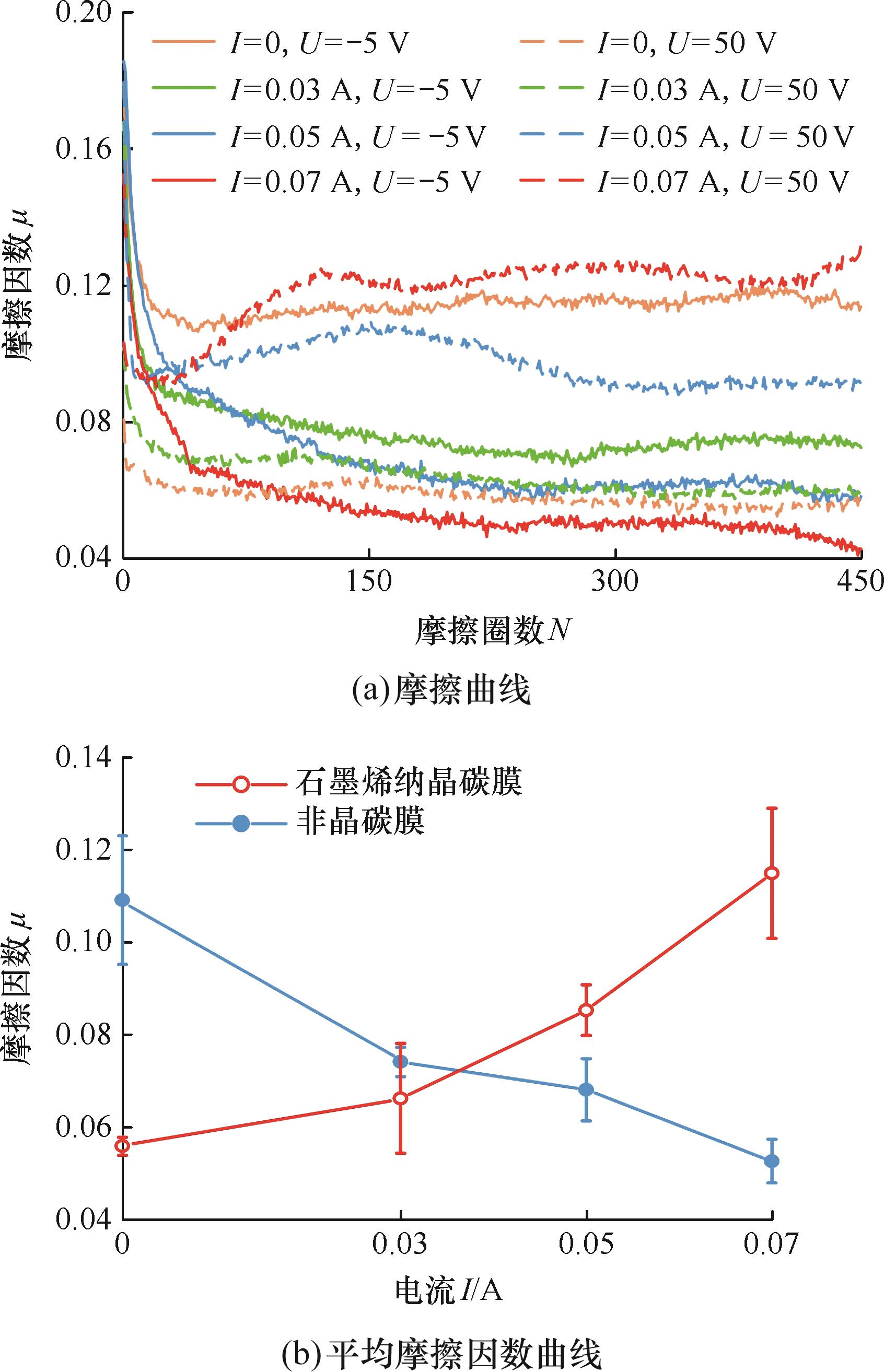

图4 室温电场耦合作用下纳米结构碳膜摩擦曲线及平均摩擦因数曲线

Fig. 4 Friction curves and average friction coefficient curves of nanostructured carbon films with different electric fields under room temperature

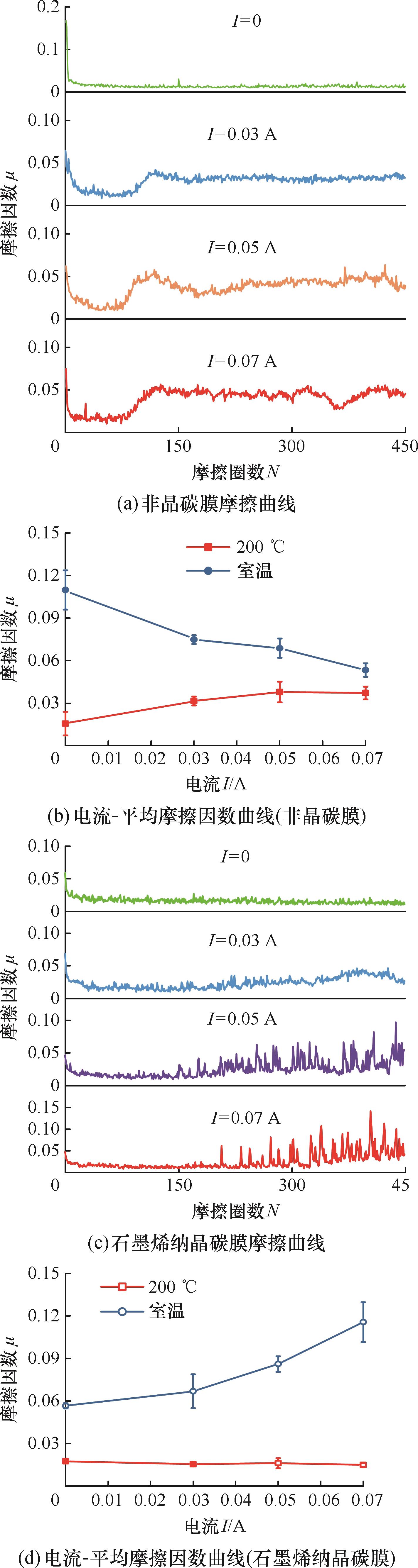

图6 高温(200 ℃)电场耦合作用下纳米结构碳膜的摩擦曲线及平均摩擦因数曲线

Fig. 6 Friction curves and average friction coefficient curves of nanostructured carbon films with different electric fields under temperature of 200 ℃

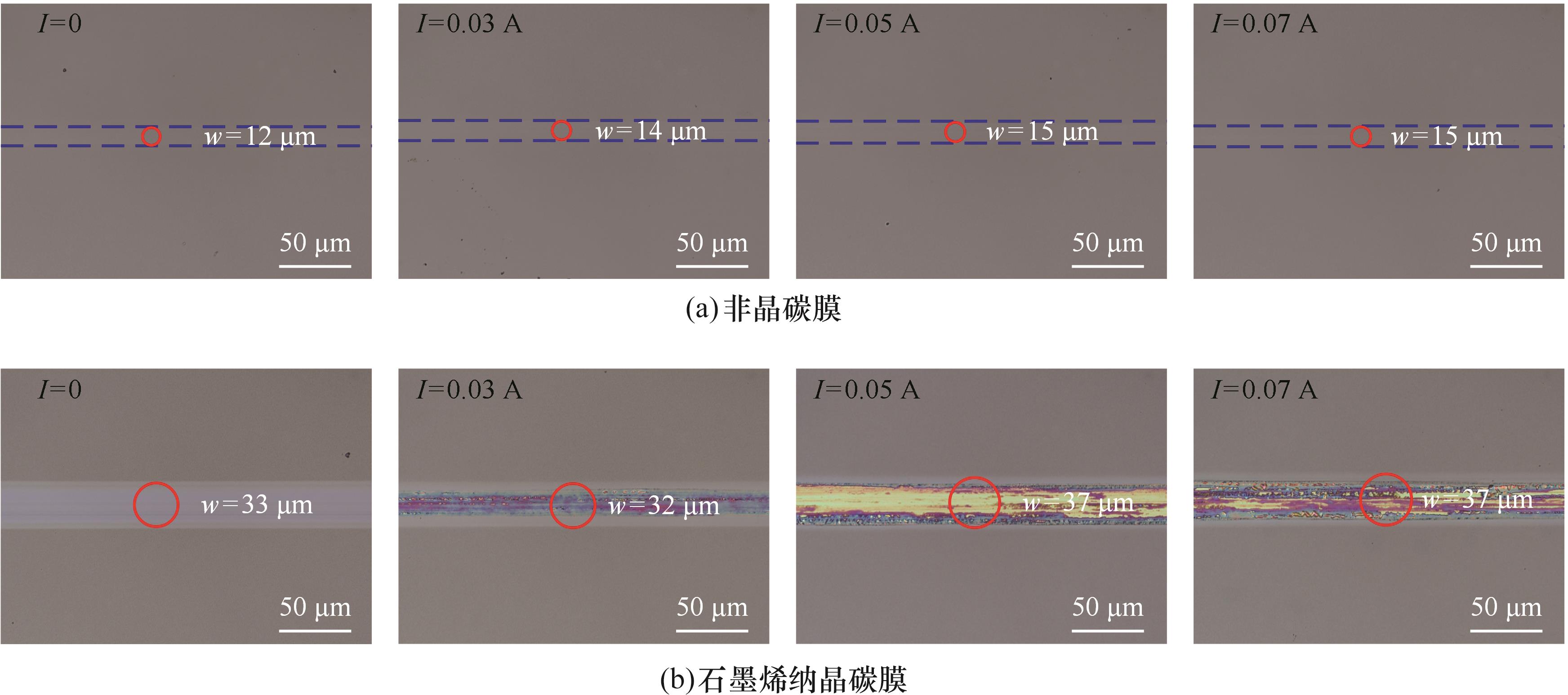

图12 高温(200 ℃)电场耦合作用下纳米结构碳膜磨痕光镜图

Fig.12 Optical images of wear tracks on the nanostructured carbon films with different electric fields under temperature of 200 ℃

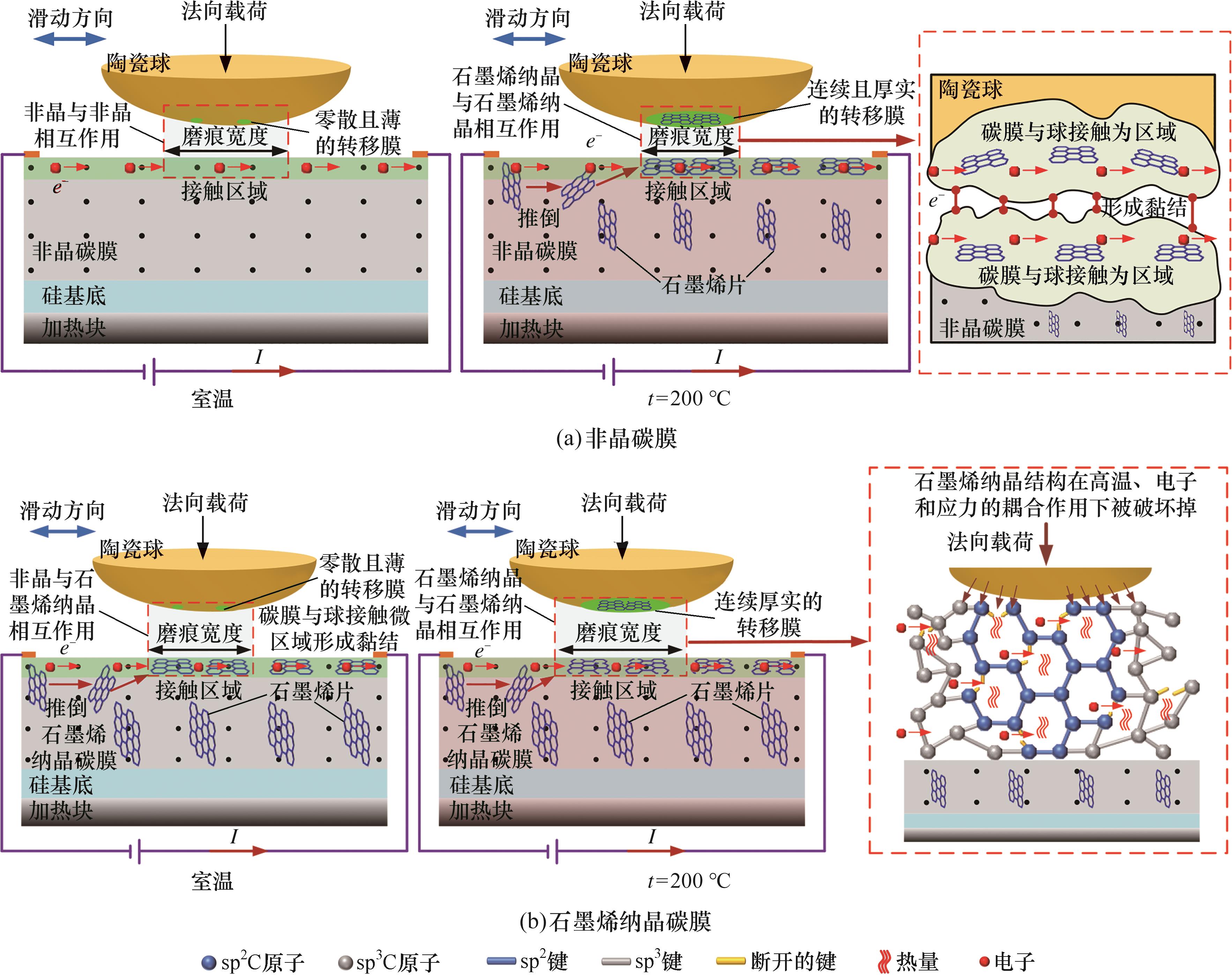

图15 温度电场耦合作用下纳米结构碳膜的摩擦机理分析图(I=0.07 A)

Fig.15 Friction mechanisms of nanostructured carbon films under the coupling effect of temperature and electric field (I=0.07 A)

| [1] | 李伟军, 李周裕, 王媛慧. DLC涂层改善气门挺柱摩擦学性能的试验研究[J]. 中国机械工程, 2015, 26(5): 704-709. |

| LI Weijun, LI Zhouyu, WANG Yuanhui. Experimental Study on Effects of DLC Coating on Improvement of Tappet Tribology Characteristics[J]. China Mechanical Engineering, 2015, 26(5): 704-709 | |

| [2] | 李迎春, 邹春生, 邱明, 等. 乏油环境下不同掺杂GLC膜的摩擦学行为[J]. 中国机械工程, 2019, 30(20): 2431-2438. |

| LI Yingchun, ZOU Chunsheng, QIU Ming, et al. Tribological Behaviors of GLC Films with Different Dopants under Starved-oil Conditions[J]. China Mechanical Engineering, 2019, 30(20): 2431-2438. | |

| [3] | 王璋, 蔡振兵, 孙阳, 等. 基于冲击动能控制的Cr-DLC涂层动力学响应和磨损行为[J]. 中国表面工程, 2017, 30(4): 78-86. |

| WANG Zhang, CAI Zhenbing, SUN Yang, et al. Dynamic Response and Wear Behavior of CR-DLC Coating under Impact Kinetic Energy Controlled Mode[J]. China Surface Engineering, 2017, 30(4): 78-86. | |

| [4] | TOLER B F, COUTU R A, McBRIDE J W. A Review of Micro-contact Physics for Microelectromechanical Systems (MEMS) Metal Contact Switches[J]. Journal of Micromechanics and Microengineering, 2013, 23(10): 103001. |

| [5] | SONG Xi, CHEN Dixiang, REN Yuan, et al. Theoretical, Simulation and Experimental Research on a Capacitive Sensor Used for Detecting the High-speed Railway Contact Line[J]. IEEE Sensors Journal, 2021, 21(22): 25775-25781. |

| [6] | ZHANG Tengfei, WAN Zhixin, DING Jicheng, et al. Microstructure and High-temperature Tribological Properties of Si-doped Hydrogenated Diamond-like Carbon Films[J]. Applied Surface Science, 2018, 435: 963-973. |

| [7] | ABOU GHARAM A, LUKITSCH M J, BALOGH M P, et al. High Temperature Tribological Behavior of W-DLC against Aluminum[J]. Surface and Coatings Technology, 2011, 206(7): 1905-1912. |

| [8] | WANG Junjun, PU Jibin, ZHANG Guangan, et al. Architecture of Superthick Diamond-like Carbon Films with Excellent High Temperature Wear Resistance[J]. Tribology International, 2015, 81: 129-138. |

| [9] | 许伟, 代明江, 林松盛, 等. 掺W类金刚石薄膜的高温摩擦学行为[J]. 摩擦学学报, 2017, 37(3): 379-386. |

| XU Wei, DAI Mingjiang, LIN Songsheng, et al. High Temperature Tribological Behavior of W-Doped Diamond-like Carbon Films[J]. Tribology, 2017, 37(3): 379-386. | |

| [10] | ZHANG Yagang, SUN Wanchang, DONG Yaru, et al. Electrodeposition and Microstructure of Ni and B Co-doped Diamond-like Carbon (Ni/B-DLC) Films[J]. Surface and Coatings Technology, 2021, 405: 126713. |

| [11] | LI Zeqing, ZHANG Honghong, XU Minglong, et al. Tribological Behavior of a Novel Si- and WC- Co-reinforced A-C Multilayer Coating at 25– 500 ℃[J]. Surface and Coatings Technology, 2023, 468: 129775. |

| [12] | WANG Xinyu, ZHANG Xiao, WANG Cong, et al. High Temperature Tribology Behavior of Silicon and Nitrogen Doped Hydrogenated Diamond-like Carbon (DLC) Coatings[J]. Tribology International, 2022, 175: 107845. |

| [13] | ZOU Yuanshu, WANG Xiaofeng, WANG Langping. Microstructure and High-temperature Tribological Properties of Ti/Si Co-doped Diamond-like Carbon Films Fabricated by Twin-targets Reactive HiPIMS[J]. Diamond and Related Materials, 2024, 141: 110573. |

| [14] | YU Weijie, WANG Junjun, HUANG Weijiu, et al. Improving High Temperature Tribological Performances of Si Doped Diamond-like Carbon by Using W Interlayer[J]. Tribology International, 2020, 146: 106241. |

| [15] | 赵新泽, 李晨诗, 吕亚茹, 等. 改善载流摩擦副摩擦学特性的表面处理技术综述[J]. 中国表面工程, 2024, 37(4): 79-101. |

| ZHAO Xinze, LI Chenshi, Yaru LYU, et al. Review of Surface Treatment Technologies for Improving Tribology Characteristics of Current-carrying Friction Pairs[J]. China Surface Engineering, 2024, 37(4): 79-101. | |

| [16] | XUE Peidong, CHEN Cheng, FAN Xue, et al. Current-carrying Friction in Carbon Coated Ball Bearing[J]. Friction, 2023, 11(11): 2008-2020. |

| [17] | WANG Hong, GAO Guoqiang, DENG Lei, et al. Study on Current-carrying Tribological Characteristics of C-Cu Sliding Electric Contacts under Different Water Content[J]. Coatings, 2023, 13(1): 42. |

| [18] | SUN Kun, FAN Xue, ZHANG Weiqiang, et al. Contact-focusing Electron Flow Induced Nanosized Graphene Sheet Formation in Amorphous Carbon Films for Fast Low-friction[J]. Carbon, 2019, 149: 45-54. |

| [19] | YANG Zhitao, HU Zelong, FAN Xue, et al. Parallel Electricity at Friction Interface Induced Fast Superlow Friction of Amorphous Carbon Films[J]. Applied Surface Science, 2022, 577: 151962. |

| [1] | 吴怀超, 吴白羽, 张秀华. 石蜡感温阀传热性能的数字仿真研究 [J]. J4, 201016, 21(16): 1921-1926. |

| [2] | 沈明学, 陈思扬, 吴海红, 肖丽, 王能慧, 季德惠. 服役环境影响下的材料载流摩擦学行为研究进展[J]. 中国机械工程, 2026, 37(1): 2-13. |

| [3] | 张梓洋, 龚雅婧, 王悦昶. 混合润滑共形接触表面摩擦学特性演变的加速试验方法[J]. 中国机械工程, 2026, 37(1): 22-29. |

| [4] | 刘秀梅, 罗云龙, 李贝贝, 刘申, 刘启航, 李永涛, 赵巧. 考虑气体溶解和温度的油气悬架输出特性研究[J]. 中国机械工程, 2025, 36(11): 2492-2500. |

| [5] | 李云峰, 李金成, 仲志丹. 基于热网络法的风电机组主轴承温度场分析[J]. 中国机械工程, 2025, 36(11): 2624-2632. |

| [6] | 邱冰静, 贾慕华, 励音骐, 吉刘斌. 基于试验测试的超重力离心模拟环境下加载缸稳压方案研究[J]. 中国机械工程, 2025, 36(08): 1651-1657. |

| [7] | 贾晨帆, 刘怀举, 朱才朝, 陈泰民, 陈进筱. 基于CatBoost的航空齿轮本体温度预测方法与验证研究[J]. 中国机械工程, 2025, 36(08): 1658-1667. |

| [8] | 崔熙颖1, 王文奇1, 徐世浩1, 刘阔1, Sahal Ahmed ELMI1, 白振华1, 2, 3. 20辊轧机非对称冷却的板形预报模型及影响因素分析[J]. 中国机械工程, 2025, 36(07): 1592-1599,1610. |

| [9] | 侯雨雷1, 李希萌1, 索槐2, 李岳1, 曾达幸3 . 正压防护服用供气背包设计及其数值模拟与实验[J]. 中国机械工程, 2025, 36(06): 1352-1362,1370. |

| [10] | 鲜超1, 3, 辛红敏2, 3, 代辉2, 程清思2. 砂布轮抛光航空发动机叶片温度仿真与试验研究[J]. 中国机械工程, 2025, 36(04): 802-810. |

| [11] | 马晓帆1, 2, 蔡志钦1, 姚斌1, 陈冠峰3. 以离散磨粒为计算单元的面齿轮展成磨削温度场预测方法[J]. 中国机械工程, 2024, 35(12): 2239-2250. |

| [12] | 范依航, 楚星雨, 郝兆朋. 基于应变梯度理论的切削加工 SiCp/Al 表面创成机理分析[J]. 中国机械工程, 2024, 35(10): 1852-1861. |

| [13] | 李瑞君, 赵亮, 姚攀, 王勇俊, 杨晓婷, 夏果, 程真英. 钨极高压微电弧温度模型的建立与验证[J]. 中国机械工程, 2024, 35(07): 1188-1193,1204. |

| [14] | 李勇凡, 宋勇, 郝木明, 庄宿国, 周芮, 李天照, 王陈寅, 任宝杰, 李小卒. 涡轮泵用球面装配机械密封热变形及磨损特性实验研究[J]. 中国机械工程, 2023, 34(13): 1550-1558. |

| [15] | 张一楠, 丁建完. 考虑温度影响的机器人关节摩擦模型[J]. 中国机械工程, 2023, 34(02): 127-134. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||