ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (11): 2792-2800.DOI: 10.3969/j.issn.1004-132X.2025.11.038

• 工程前沿 • 上一篇

李成展1( ), 郭鹏程1,2,3(

), 郭鹏程1,2,3( ), 徐从昌3, 李落星3, 肖永富4, 蒋淑霞1

), 徐从昌3, 李落星3, 肖永富4, 蒋淑霞1

收稿日期:2024-06-26

出版日期:2025-11-25

发布日期:2025-12-09

通讯作者:

郭鹏程

作者简介:李成展,男,1999年生,硕士研究生。研究方向为整车性能优化和车身钢镁连接技术。E-mail: lichengzhan12@163.com基金资助:

Chengzhan LI1( ), Pengcheng GUO1,2,3(

), Pengcheng GUO1,2,3( ), Congchang XU3, Luoxing LI3, Yongfu XIAO4, Shuxia JIANG1

), Congchang XU3, Luoxing LI3, Yongfu XIAO4, Shuxia JIANG1

Received:2024-06-26

Online:2025-11-25

Published:2025-12-09

Contact:

Pengcheng GUO

摘要:

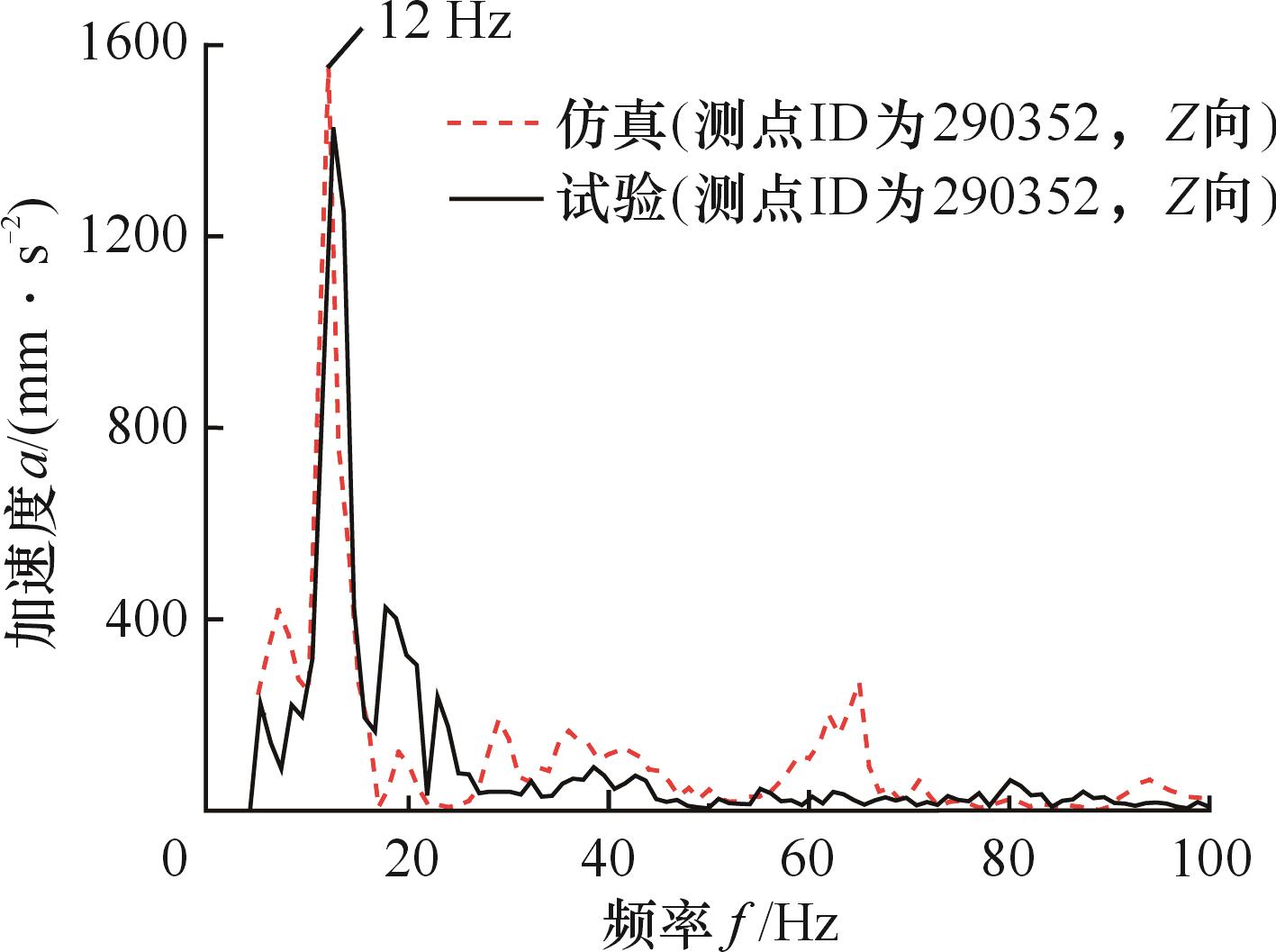

针对传统NVH分析很难准确提取和预测车门转动过程中的动态激励与响应的难题,提出一种基于刚柔耦合识别多自由度激励的方法并应用于振动传递函数的分析。以某车型在关门过程中出现的窗框异常抖动为研究目标,采用多体动力学方法建立整车刚柔耦合分析模型,提取限位器安装点的多自由度加速度动态激励进行传递函数分析。仿真与试验对比结果表明,两者均在12 Hz处出现较为一致的振动加速度峰值,验证了刚柔耦合模型的准确性。基于此,通过仿真分析了影响关门过程窗框抖动的关键因素,得出以限位器结构为核心优化目标。据此提出优化方案,并进行动态激励下的振动传递函数分析,研究结果表明,优化限位器结构能够显著降低关门过程的窗框抖动水平。

中图分类号:

李成展, 郭鹏程, 徐从昌, 李落星, 肖永富, 蒋淑霞. 车门限位多自由度激励的刚柔耦合识别及关门窗框抖动优化[J]. 中国机械工程, 2025, 36(11): 2792-2800.

Chengzhan LI, Pengcheng GUO, Congchang XU, Luoxing LI, Yongfu XIAO, Shuxia JIANG. Rigid-flexible Coupling Identification of MDOF Excitation for Door Limiter and Shaking Optimization of Window Frame during Closing[J]. China Mechanical Engineering, 2025, 36(11): 2792-2800.

| 测点 | X向幅值 | Y向幅值 | Z向幅值 |

|---|---|---|---|

| 后点 | 1394.3 | 1203.5 | 1527.8 |

| 限位器点 | 1218.6 | 1086.5 | 1358.4 |

| 门把手点 | 1395.4 | 1105.7 | 1279.6 |

表1 测点加速度试验结果对比 (mm/s2)

Tab.1 Comparison of measurement point acceleration test

| 测点 | X向幅值 | Y向幅值 | Z向幅值 |

|---|---|---|---|

| 后点 | 1394.3 | 1203.5 | 1527.8 |

| 限位器点 | 1218.6 | 1086.5 | 1358.4 |

| 门把手点 | 1395.4 | 1105.7 | 1279.6 |

| 模态阶数 | 试验/Hz | 仿真/Hz | 精度/% |

|---|---|---|---|

| 1 | 35.0 | 36.33 | 96.20 |

| 2 | 43.5 | 46.14 | 93.93 |

| 3 | 46.8 | 49.52 | 94.19 |

| 4 | 55.8 | 55.11 | 98.76 |

| 5 | 59.3 | 56.54 | 95.35 |

| 6 | 69.7 | 71.33 | 97.66 |

| 7 | 75.1 | 71.67 | 95.43 |

| 8 | 87.1 | 85.76 | 98.46 |

表2 车门单体模态的仿真与试验结果对比

Tab.2 Comparison of simulation and experimental results of door monomer modes

| 模态阶数 | 试验/Hz | 仿真/Hz | 精度/% |

|---|---|---|---|

| 1 | 35.0 | 36.33 | 96.20 |

| 2 | 43.5 | 46.14 | 93.93 |

| 3 | 46.8 | 49.52 | 94.19 |

| 4 | 55.8 | 55.11 | 98.76 |

| 5 | 59.3 | 56.54 | 95.35 |

| 6 | 69.7 | 71.33 | 97.66 |

| 7 | 75.1 | 71.67 | 95.43 |

| 8 | 87.1 | 85.76 | 98.46 |

| 模态振型 | 试验/Hz | 仿真/Hz | 精度/% |

|---|---|---|---|

| 车门上下摆动 | 13.6 | 12.3 | 90.37 |

| 车门前后摆动 | 24.1 | 21.3 | 88.17 |

| 车门绕铰链扭转 | 24.9 | 23.9 | 95.86 |

表3 整车模态的仿真与试验结果对比

Tab.3 Comparison of simulation and test results of whole vehicle modal

| 模态振型 | 试验/Hz | 仿真/Hz | 精度/% |

|---|---|---|---|

| 车门上下摆动 | 13.6 | 12.3 | 90.37 |

| 车门前后摆动 | 24.1 | 21.3 | 88.17 |

| 车门绕铰链扭转 | 24.9 | 23.9 | 95.86 |

| 类型 | X向总幅值 | Y向总幅值 | Z向总幅值 |

|---|---|---|---|

| 试验 | 8800 | 12 900 | 8800 |

| 仿真 | 8100 | 13 500 | 9600 |

| 精度/% | 92 | 96 | 92 |

表4 后点加速度响应曲线总幅值 (mm/s2)

Tab.4 Total amplitude of the acceleration response curve of the rear point of the door

| 类型 | X向总幅值 | Y向总幅值 | Z向总幅值 |

|---|---|---|---|

| 试验 | 8800 | 12 900 | 8800 |

| 仿真 | 8100 | 13 500 | 9600 |

| 精度/% | 92 | 96 | 92 |

图14 车门后点Z向加速度频域响应的仿真与试验对比

Fig.14 Comparison of simulation and experiment on frequency domain response of Z direction acceleration at rear point of door

| 类型 | X向幅值 | Y向幅值 | Z向幅值 |

|---|---|---|---|

| 原方案 | 1347.5 | 1221.5 | 1557.6 |

| 优化车身刚度 | 1204.8 | 1195.3 | 1514.3 |

| 优化车门刚度 | 1256.5 | 1186.7 | 1550.2 |

表5 优化前后加速度幅值的对比 (mm/s2)

Tab.5 Comparison of acceleration amplitude before and after optimization

| 类型 | X向幅值 | Y向幅值 | Z向幅值 |

|---|---|---|---|

| 原方案 | 1347.5 | 1221.5 | 1557.6 |

| 优化车身刚度 | 1204.8 | 1195.3 | 1514.3 |

| 优化车门刚度 | 1256.5 | 1186.7 | 1550.2 |

| [1] | 祝丹晖, 杨乐, ZHANG Charles. 基于某纯电动车的低频制动噪声优化研究[J]. 汽车工程, 2021, 43(9): 1411-1417. |

| ZHU Danhui, YANG Le, ZHANG Charles. Research on Low Frequency Braking Noise Optimization Based on a Pure Electric Vehicle[J]. Automotive Engineering, 2021, 43(9): 1411-1417. | |

| [2] | 胡朝晖, 成艾国. 多学科设计优化在滑移门轻量化中的应用研究[J]. 汽车工程, 2010, 32(10): 897-901. |

| HU Zhaohui, CHENG Aiguo. Application of Multidisciplinary Design Optimization in Lightweight Sliding Door[J]. Automotive Engineering, 2010, 32(10): 897-901. | |

| [3] | 周庭荣, 王良模, 王陶, 等. 轻型客车悬架系统垂向动力学优化研究[J]. 振动与冲击, 2023, 42(14): 131-137. |

| ZHOU Tingrong, WANG Liangmo, WANG Tao, et al. Research on Vertical Dynamics Optimization of Light Bus Suspension System[J]. Journal of Vibration and Shock, 2023, 42(14):131-137. | |

| [4] | 王少华, 谭博欢, 张邦基, 等. 纯电动客车振动试验分析及动力总成隔振优化[J]. 振动与冲击, 2021, 40(1): 226-232. |

| WANG Shaohua, TAN Bohuan, ZHANG Bangji, et al. Vibration Test Analysis of Pure Electric Bus and Optimization of Powertrain Vibration Isolation [J]. Journal of Vibration and Shock, 2021, 40(1): 226-232. | |

| [5] | 陈江艳, 贺岩松, 陈远政. 电动汽车低频轰鸣声故障诊断与改进[J]. 振动、测试与诊断, 2023, 43(2): 343-348. |

| CHEN Jiangyan, HE Yansong, CHEN Yuanzheng. Fault Diagnosis and Optimization of Low Frequency Booming Noise for Electric Vehicle[J]. Journal of Vibration,Measurement & Diagnosis, 2023, 43(2): 343-348. | |

| [6] | YAN X, JIANG D, BAI Y, et al. A Research on Vibration Perfor Mance of Light Duty Truck Doors Based on Road Load Spectrum[C]∥Proceedings of China SAE Congress. Shanghai, 2018:709-721. |

| [7] | 胡强, 陈宇强, 陈梓铭, 等. 车门框密封条断面结构的多目标优化[J]. 汽车技术, 2019(4): 58-62. |

| HU Qiang, CHEN Yuqiang, CHEN Ziming, et al. Multi-objective Optimization of Section Structure of Door Frame Seal[J]. Automotive Technology, 2019(4): 58-62. | |

| [8] | XIA E, CHEN Z, XUE Z, et al. An Equivalent NVH Model of Vehicle Door Seal Strip and Its Application in Door Vibration Problem[J]. Applied Acoustics, 2021, 179: 108063. |

| [9] | LIU Z, GAO Y, YANG J, et al. Effect of Discretized Transfer Paths on Abnormal Vibration Analysis and Door Structure Improvement to Reduce Its Vibration in the Door Slamming Event[J]. Applied Acoustics, 2021, 183: 108306. |

| [10] | 刘哲, 高云凯, 徐翔, 等. 基于传递路径分析的车门下位玻璃异常振动预测与试验验证[J]. 振动与冲击, 2021, 40(23): 152-158. |

| LIU Zhe, GAO Yunkai, XU Xiang, et al. Abnormal Vibration Prediction and Test Verification of Door Lower Glass Based on Transfer Path Analysis[J]. Journal of Vibration and Shock, 2021, 40(23): 152-158. | |

| [11] | 刘哲, 高云凯, 徐翔, 等. 车门玻璃下位振动传递路径建模及优化分析[J]. 振动、测试与诊断, 2021, 41(1): 69-75. |

| LIU Zhe, GAO Yunkai, XU Xiang, et al. Modeling and Optimization Analysis of Vibration Transmission Path under Door Glass[J]. Journal of Vibration,Measurement & Diagnosis, 2021, 41(1): 69-75. | |

| [12] | 陈梓铭, 郭鹏程, 熊勇, 等. 基于响应面模型的滑移门动力学特性多目标优化[J]. 湖南大学学报(自然科学版), 2019, 46(4): 17-24. |

| CHEN Ziming, GUO Pengcheng, XIONG Yong, et al. Multi-objective Optimization of Sliding Gate Dynamics Based on Response Surface Model[J]. Journal of Hunan University(Natural Science Edition), 2019, 46(4): 17-24. | |

| [13] | LIU Y, LI J, XIA Q, et al. A Simulation on Door-closing Dynamics of a SUV Vehicle[J]. Journal of Automobile Engineering, 2024, 238(1): 100-109. |

| [14] | 张安琪, 曹荣刚, 周宇, 等. 基于2D-FFT与2D-CFAR的调频引信快速高精度信号处理方法研究[J/OL].北京航空航天大学学报.[2024-06-26].. |

| ZHANG Anqi, CAO Ronggang, ZHOU Yu, et al. Research on Fast and High Precision Signal Processing Method of Frequency-modulated Fuze Based on 2D-FFT and 2D-CFAR[J/OL].Journal of Beijing University of Aeronautics and Astronautics.[2024-06-26].. | |

| [15] | PARK T Y, JEON S H, KIM S J, et al. Experimental Validation of Fatigue Life of CCGA 624 Package with Initial Contact Pressure of Thermal Gap Pads under Random Vibration Excitation[J]. International Journal of Aerospace Engineering, 2018(3): 1-12. |

| [16] | 何智成, 尹瑞林, 郝耀东. 基于传递路径分析的动力传动系统NVH性能匹配研究[J]. 汽车工程, 2017, 39(3): 343-350. |

| HE Zhicheng, YIN Ruilin, HAO Yaodong. Research on NVH Performance Matching of Powertrain Based on Transfer Path Analysis[J]. Automotive Engineering, 2017, 39(3): 343-350. | |

| [17] | 周生通, 谢阳泉, 肖乾, 等. 轮轨接触弹性约束下动力轮对转子系统振动特性分析[J]. 振动与冲击, 2023, 42(22): 230-240. |

| ZHOU Shengtong, XIE Yangquan, XIAO Qian, et al. Vibration Characteristics Analysis of Power Wheel Counterrotating Subsystem under Wheel-rail Contact Elastic Constraints [J]. Journal of Vibration and Shock, 2023, 42(22): 230-240. | |

| [18] | SUN Y, PENG Z R, YANG D, et al. Dynamics of a Rigid-flexible Coupling System in a Uniform Flow[J]. Journal of Fluid Mechanics, 2022, 943: A44. |

| [19] | 商德勇, 黄欣怡, 黄云山, 等. 基于Kane方程的Delta并联机器人刚柔耦合动力学研究[J]. 机械工程学报, 2024, 60(7): 124-133. |

| SHANG Deyong, HUANG Xinyi, HUANG Yunshan, et al. Research on Rigid-flexible Coupling Dynamics of Delta Parallel Robot Based on Kane Equation[J]. Journal of Mechanical Engineering, 2024, 60(7): 124-133. | |

| [20] | 陈梓铭, 薛志刚, 张松, 等.基于ADAMS与Simulink联合仿真的滑移门关闭能量分析[J]. 中国机械工程, 2020, 31(8): 924-930. |

| CHEN Ziming, XUE Zhigang, ZHANG Song, et al. Analysis of Sliding Gate Closing Energy Based on ADAMS and Simulink Co-simulation[J]. China Mechanical Engineering, 2020, 31(8): 924-930. | |

| [21] | 陈俊菲, 张元标, 林聪. 随机振动下产品包装系统的传递路径数值仿真与实验研究[J]. 振动工程学报, 2023, 36(6): 1633-1646. |

| CHEN Junfei, ZHANG Yuanbiao, LIN Cong. Numerical Simulation and Experimental Study on Transfer Path of Product Packaging System under Random Vibration[J]. Journal of Vibration Engineering, 2023, 36(6): 1633-1646. | |

| [22] | 雷思勉, 葛耀君, 李奇. 考虑时变特性的车-桥耦合系统非平稳振动频域方法研究[J]. 铁道科学与工程学报, 2024, 21(5): 1930-1941. |

| LEI Simian, GE Yaojun, LI Qi. Study on Frequency Domain Method of Non-stationary Vibration of Vehicle-bridge Coupling System Considering Time-varying Characteristics[J]. Journal of Railway Science and Engineering, 2024, 21(5): 1930-1941. | |

| [23] | 刘丹, 王琥. 基于Lanczos法的模态重分析法在拓扑优化中的应用[J]. 中国机械工程, 2015, 26(11): 1516-1520. |

| LIU Dan, WANG Hu. Application of Modal Reanalysis Method Based on Lanczos Method in Topology Optimization [J]. China Mechanical Engineering, 2015, 26(11): 1516-1520. |

| [1] | 张志刚1, 靳勇利1, 王栋银1, 付志军1, 秦国栋2. 基于动力学降噪模型的蛇形臂机器人末端轨迹跟随算法[J]. 中国机械工程, 2025, 36(03): 407-413. |

| [2] | 刘延浩, 倪冰雨, 田万一, 姜潮. 区间过程激励下刚柔耦合系统动态不确定性分析的序列模拟方法[J]. 中国机械工程, 2024, 35(05): 770-783. |

| [3] | 周松, 陈宇, 董红亮, 高翔, 申娟, 周佳, 万鑫铭. 一种新型商用车驾驶室多轴道路虚拟试验研究[J]. 中国机械工程, 2023, 34(10): 1241-1250. |

| [4] | 张陈曦, 赵又群, 冯世林, 郑鑫, 徐瀚. 伪刚体柔体耦合的新式免充气轮胎刚度分析[J]. 中国机械工程, 2021, 32(09): 1051-1060,1072. |

| [5] | 王昆鹏1,2;肖晓华1,2;朱海燕1,2;曾杰1,2. 柔性牵引器刚柔耦合动力学特征及结构优化[J]. 中国机械工程, 2020, 31(08): 915-923,930. |

| [6] | 刘俊1;张海剑1;王威1;刘亚军1;周福庚2. 基于轮胎六分力的某商用车车架疲劳分析[J]. 中国机械工程, 2019, 30(21): 2583-2589. |

| [7] | 刘俊1;刘亚军1;张少辉1;杨建森2;董强强2. 基于虚拟迭代及有限元理论的某中型货车驾驶室疲劳寿命研究[J]. 中国机械工程, 2018, 29(13): 1588-1595. |

| [8] | 赵燕;阮成明;王松伟. 刚柔耦合柔性机械手二阶理论精准建模及实验研究[J]. 中国机械工程, 2018, 29(02): 205-210. |

| [9] | 邱雪松, 肖超, 谭候金, 侯雨雷, 周玉林. 大型机器人冲压生产线多软件联合仿真[J]. 中国机械工程, 2016, 27(06): 772-777. |

| [10] | 金鑫, 周克栋, 赫雷, 黄雪鹰, 张俊斌. 新型射击试验用枪架设计与分析[J]. 中国机械工程, 2015, 26(24): 3323-3326. |

| [11] | 李欣冉, 陈无畏, 陈晓新. 基于刚柔耦合模型的悬架NVH性能研究[J]. 中国机械工程, 2014, 25(7): 978-983. |

| [12] | 魏小辉, 王钰龙, 印寅, 聂宏, 倪华近. 某起落架收放联动机构故障分析及改进设计[J]. 中国机械工程, 2014, 25(3): 399-403. |

| [13] | 伍文广, 谷正气, 米承继. 基于刚柔耦合模型的电动轮自卸车平顺性分析与优化[J]. 中国机械工程, 2014, 25(20): 2819-2824. |

| [14] | 张军峰, 贺岩松, 杨海威, 黄勇. 基于俯仰角加速度的驾驶室悬置系统修改[J]. 中国机械工程, 2012, 23(18): 2258-2262. |

| [15] | 王斌锐1, 2, 方水光1, 严冬明1. 机器人手臂的刚柔耦合建模及摆动模态对比[J]. 中国机械工程, 2012, 23(17): 2092-2097. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||