ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2026, Vol. 37 ›› Issue (1): 135-146.DOI: 10.3969/j.issn.1004-132X.2026.01.015

陈维1,2( ), 刘美红2, 邓强国2, 毛文元1, 孙雪剑1, 许恒杰1(

), 刘美红2, 邓强国2, 毛文元1, 孙雪剑1, 许恒杰1( )

)

收稿日期:2024-10-23

出版日期:2026-01-25

发布日期:2026-02-05

通讯作者:

许恒杰

作者简介:陈维,女,1993年生,博士研究生。研究方向为流体密封技术。发表论文5篇。E-mail: 625371268@qq.com基金资助:

CHEN Wei1,2( ), LIU Meihong2, DENG Qiangguo2, MAO Wenyuan1, SUN Xuejian1, XU Hengjie1(

), LIU Meihong2, DENG Qiangguo2, MAO Wenyuan1, SUN Xuejian1, XU Hengjie1( )

)

Received:2024-10-23

Online:2026-01-25

Published:2026-02-05

Contact:

XU Hengjie

摘要:

针对高速、高压工况下CO2混合气体干气密封实际气体效应、湍流效应及端面热力变形显著的问题,建立了考虑实际气体与湍流效应的CO2混合气体干气密封双向耦合热力变形模型,采用有限差分法与有限单元法联立求解,分析了CO2混合气体干气密封热力变形行为,探讨了不同运行工况下的湍流效应对密封端面倾斜度的影响规律。结果表明:湍流效应会减小平衡膜厚,升高气膜与密封环温度,且对密封端面力变形的影响较小;低转速下的湍流效应会减小密封端面的热力总变形,高转速工况则相反;高进口压力时,湍流效应可有效增大密封端面间的收敛形间隙;低进口温度时,湍流效应可有效抑制密封端面发散形间隙的形成。

中图分类号:

陈维, 刘美红, 邓强国, 毛文元, 孙雪剑, 许恒杰. 高参数CO2混合气体干气密封湍流润滑双向耦合热力变形特性[J]. 中国机械工程, 2026, 37(1): 135-146.

CHEN Wei, LIU Meihong, DENG Qiangguo, MAO Wenyuan, SUN Xuejian, XU Hengjie. Thermal-mechanical Deformation Characteristics of High Parameter CO2 Mixed Gases Dry Gas Seals under Turbulence Lubrication with a Two-way Coupling Model[J]. China Mechanical Engineering, 2026, 37(1): 135-146.

| 转速n/(r·min | 最大轴向力变形 | 最大轴向热变形 | ||||

|---|---|---|---|---|---|---|

| 文献[ | 本文/μm | 相对 误差/% | 文献[ | 本文/μm | 相对 误差/% | |

| 5000 | 0.054 | 0.055 | 1.852 | 5.171 | 5.190 | 0.367 |

| 7500 | 0.063 | 0.064 | 1.587 | 5.177 | 5.201 | 0.464 |

| 10 000 | 0.075 | 0.078 | 4.000 | 5.187 | 5.211 | 0.463 |

| 12 500 | 0.090 | 0.095 | 5.556 | 5.198 | 5.219 | 0.404 |

| 15 000 | 0.116 | 0.123 | 6.034 | 5.212 | 5.228 | 0.307 |

表1 热力变形计算程序合理性验证

Tab 1 Verification of rationality for thermal-mechanical deformation calculation program

| 转速n/(r·min | 最大轴向力变形 | 最大轴向热变形 | ||||

|---|---|---|---|---|---|---|

| 文献[ | 本文/μm | 相对 误差/% | 文献[ | 本文/μm | 相对 误差/% | |

| 5000 | 0.054 | 0.055 | 1.852 | 5.171 | 5.190 | 0.367 |

| 7500 | 0.063 | 0.064 | 1.587 | 5.177 | 5.201 | 0.464 |

| 10 000 | 0.075 | 0.078 | 4.000 | 5.187 | 5.211 | 0.463 |

| 12 500 | 0.090 | 0.095 | 5.556 | 5.198 | 5.219 | 0.404 |

| 15 000 | 0.116 | 0.123 | 6.034 | 5.212 | 5.228 | 0.307 |

| 名称 | 数值 |

|---|---|

| 静环外半径ro/mm | 42 |

| 静环内半径ri/mm | 30 |

| 动环外半径r1/mm | 42 |

| 动环槽根半径rg/mm | 36 |

| 动环内半径r2/mm | 27.5 |

| 平衡半径rb/mm | 32.8 |

| 计算区域角度θ/rad | 0~π/6 |

| 螺旋角β/(°) | 15 |

| 槽宽比γ | 1 |

| 槽深hg/μm | 5 |

| 动静环厚度Hr、Hs/mm | 10 |

| 动环外周与密封腔内壁间隙wr/mm | 20 |

| 静环外周与密封腔内壁间隙ws/mm | 20 |

| 弹簧力Fsp/N | 60 |

| 轴套力Fsh/N | 1600 |

| 定压比热容Cp/(J·kg | 710 |

| 热导率λ/(W·m | 57 |

| 密度ρm/(kg·m | 3150 |

| 热膨胀系数αT/K | 3.4×10-6 |

| 弹性模量Em/GPa | 386 |

| 泊松比νp | 0.14 |

表2 密封环结构参数与材料参数

Tab.2 Structural parameters and material properties of seal rings

| 名称 | 数值 |

|---|---|

| 静环外半径ro/mm | 42 |

| 静环内半径ri/mm | 30 |

| 动环外半径r1/mm | 42 |

| 动环槽根半径rg/mm | 36 |

| 动环内半径r2/mm | 27.5 |

| 平衡半径rb/mm | 32.8 |

| 计算区域角度θ/rad | 0~π/6 |

| 螺旋角β/(°) | 15 |

| 槽宽比γ | 1 |

| 槽深hg/μm | 5 |

| 动静环厚度Hr、Hs/mm | 10 |

| 动环外周与密封腔内壁间隙wr/mm | 20 |

| 静环外周与密封腔内壁间隙ws/mm | 20 |

| 弹簧力Fsp/N | 60 |

| 轴套力Fsh/N | 1600 |

| 定压比热容Cp/(J·kg | 710 |

| 热导率λ/(W·m | 57 |

| 密度ρm/(kg·m | 3150 |

| 热膨胀系数αT/K | 3.4×10-6 |

| 弹性模量Em/GPa | 386 |

| 泊松比νp | 0.14 |

| 转速n/(r·min | 10 000 | 20 000 | 30 000 | 40 000 | 50 000 | |

|---|---|---|---|---|---|---|

静环端面的力致 倾斜度Δψf/10 | 层流 | |||||

| 湍流 | ||||||

动环端面的力致 倾斜度Δψf/10 | 层流 | 11.97 | 10.65 | 8.44 | 5.35 | 1.38 |

| 湍流 | 11.97 | 10.65 | 8.43 | 5.36 | 1.40 | |

密封端面的力致 倾斜度Δψf/10 | 层流 | 2.31 | ||||

| 湍流 | 2.23 | |||||

静环端面的热致 倾斜度Δψt/10 | 层流 | 10.09 | 21.31 | 36.25 | ||

| 湍流 | 5.17 | 20.33 | 43.42 | 68.42 | ||

动环端面的热致 倾斜度Δψt/10 | 层流 | 5.91 | 13.66 | 23.83 | ||

| 湍流 | 2.36 | 11.76 | 26.50 | 43.83 | ||

密封端面的热致 倾斜度Δψt/10 | 层流 | -0.29 | 16.00 | 34.97 | 60.08 | |

| 湍流 | 7.53 | 32.09 | 69.92 | 112.24 | ||

密封端面的热力 总倾斜度 Δψtf/10 | 层流 | 12.69 | 26.69 | 47.56 | ||

| 湍流 | 6.00 | 25.34 | 60.20 | 101.38 | ||

表3 层流、湍流模型中密封端面倾斜度随转速的变化

Tab.3 The variation of sealing end face inclination with rotational speed in laminar and turbulent flow models

| 转速n/(r·min | 10 000 | 20 000 | 30 000 | 40 000 | 50 000 | |

|---|---|---|---|---|---|---|

静环端面的力致 倾斜度Δψf/10 | 层流 | |||||

| 湍流 | ||||||

动环端面的力致 倾斜度Δψf/10 | 层流 | 11.97 | 10.65 | 8.44 | 5.35 | 1.38 |

| 湍流 | 11.97 | 10.65 | 8.43 | 5.36 | 1.40 | |

密封端面的力致 倾斜度Δψf/10 | 层流 | 2.31 | ||||

| 湍流 | 2.23 | |||||

静环端面的热致 倾斜度Δψt/10 | 层流 | 10.09 | 21.31 | 36.25 | ||

| 湍流 | 5.17 | 20.33 | 43.42 | 68.42 | ||

动环端面的热致 倾斜度Δψt/10 | 层流 | 5.91 | 13.66 | 23.83 | ||

| 湍流 | 2.36 | 11.76 | 26.50 | 43.83 | ||

密封端面的热致 倾斜度Δψt/10 | 层流 | -0.29 | 16.00 | 34.97 | 60.08 | |

| 湍流 | 7.53 | 32.09 | 69.92 | 112.24 | ||

密封端面的热力 总倾斜度 Δψtf/10 | 层流 | 12.69 | 26.69 | 47.56 | ||

| 湍流 | 6.00 | 25.34 | 60.20 | 101.38 | ||

| 进口压力po/MPa | 6 | 8 | 10 | 12 | 14 | |

|---|---|---|---|---|---|---|

静环端面力致倾 斜度Δψf/10 | 层流 | |||||

| 湍流 | ||||||

动环端面力致倾 斜度Δψf/10 | 层流 | 3.84 | 8.44 | 13.04 | 17.67 | |

| 湍流 | 3.83 | 8.43 | 13.04 | 17.65 | ||

密封端面力致倾 斜度Δψf/10 | 层流 | 0.62 | 6.80 | |||

| 湍流 | 1.54 | |||||

静环端面热致倾 斜度Δψt/10 | 层流 | 19.57 | 15.42 | 10.09 | 2.45 | |

| 湍流 | 22.95 | 21.74 | 20.33 | 18.53 | 15.82 | |

动环端面热致倾 斜度Δψt/10 | 层流 | 13.28 | 9.45 | 5.91 | 1.44 | |

| 湍流 | 15.45 | 13.57 | 11.76 | 9.88 | 7.83 | |

密封端面热致倾 斜度Δψt/10 | 层流 | 32.85 | 24.86 | 16.00 | 3.89 | |

| 湍流 | 38.40 | 35.31 | 32.09 | 28.41 | 23.65 | |

密封端面热力总倾 斜度Δψtf/10 | 层流 | 23.73 | 17.59 | 12.69 | 4.52 | 1.38 |

| 湍流 | 28.52 | 26.57 | 25.34 | 25.28 | 25.19 | |

表4 层流、湍流模型中密封端面倾斜度随进口压力的变化

Tab.4 The variation of sealing end face inclination with inlet pressure in laminar and turbulent flow models

| 进口压力po/MPa | 6 | 8 | 10 | 12 | 14 | |

|---|---|---|---|---|---|---|

静环端面力致倾 斜度Δψf/10 | 层流 | |||||

| 湍流 | ||||||

动环端面力致倾 斜度Δψf/10 | 层流 | 3.84 | 8.44 | 13.04 | 17.67 | |

| 湍流 | 3.83 | 8.43 | 13.04 | 17.65 | ||

密封端面力致倾 斜度Δψf/10 | 层流 | 0.62 | 6.80 | |||

| 湍流 | 1.54 | |||||

静环端面热致倾 斜度Δψt/10 | 层流 | 19.57 | 15.42 | 10.09 | 2.45 | |

| 湍流 | 22.95 | 21.74 | 20.33 | 18.53 | 15.82 | |

动环端面热致倾 斜度Δψt/10 | 层流 | 13.28 | 9.45 | 5.91 | 1.44 | |

| 湍流 | 15.45 | 13.57 | 11.76 | 9.88 | 7.83 | |

密封端面热致倾 斜度Δψt/10 | 层流 | 32.85 | 24.86 | 16.00 | 3.89 | |

| 湍流 | 38.40 | 35.31 | 32.09 | 28.41 | 23.65 | |

密封端面热力总倾 斜度Δψtf/10 | 层流 | 23.73 | 17.59 | 12.69 | 4.52 | 1.38 |

| 湍流 | 28.52 | 26.57 | 25.34 | 25.28 | 25.19 | |

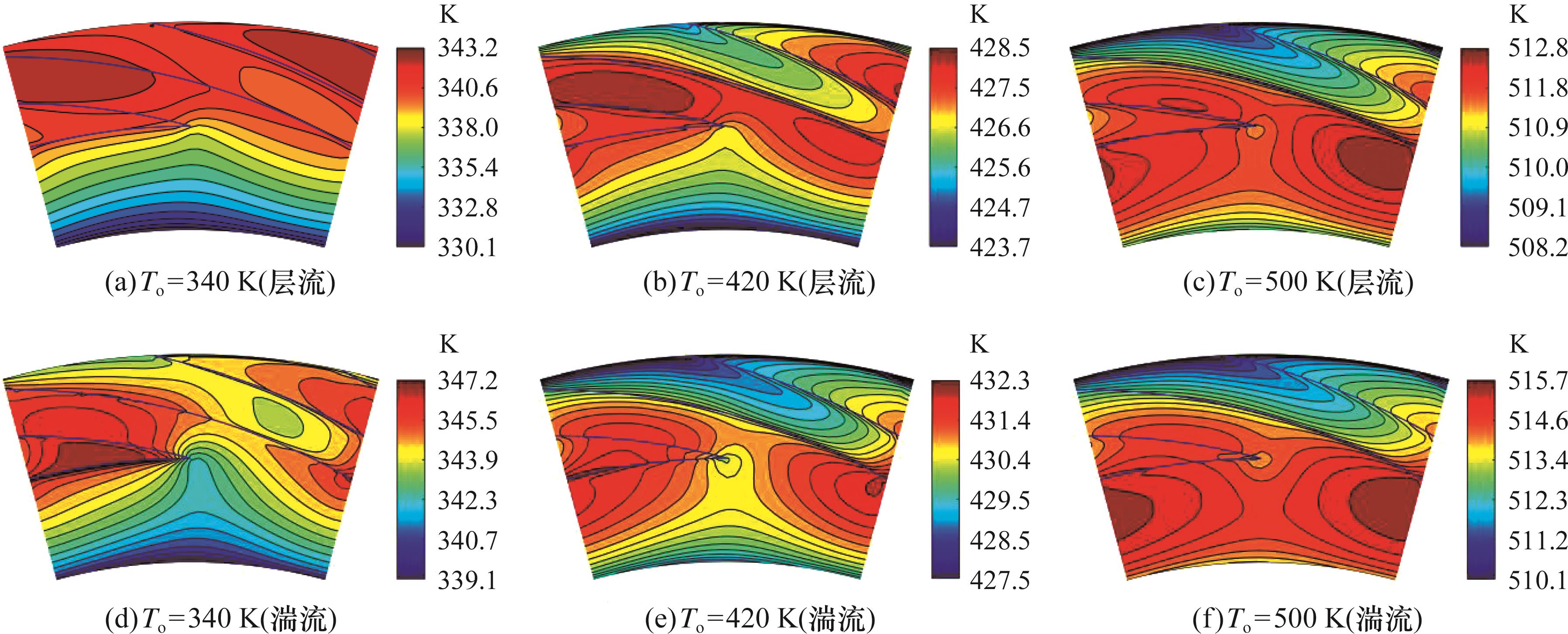

图10 层流、湍流模型中气膜温度分布随进口温度的变化规律

Fig.10 The variation law of gas film temperature distribution with inlet temperature in laminar and turbulent flow models

| 进口温度To/K | 340 | 380 | 420 | 460 | 500 | |

|---|---|---|---|---|---|---|

静环端面力致倾 斜度Δψf/10 | 层流 | |||||

| 湍流 | ||||||

动环端面力致倾 斜度Δψf/10 | 层流 | 8.46 | 8.44 | 8.44 | 8.44 | 8.44 |

| 湍流 | 8.50 | 8.44 | 8.43 | 8.42 | 8.43 | |

密封端面力致倾 斜度Δψf/10 | 层流 | 0.94 | ||||

| 湍流 | 0.86 | |||||

静环端面热致倾 斜度Δψt/10 | 层流 | 10.09 | 16.14 | 20.94 | ||

| 湍流 | 5.11 | 15.90 | 20.33 | 23.56 | 26.69 | |

动环端面热致倾 斜度Δψt/10 | 层流 | 0.08 | 5.91 | 9.62 | 12.68 | |

| 湍流 | 2.08 | 8.47 | 11.76 | 14.20 | 16.35 | |

密封端面热致倾 斜度Δψt/10 | 层流 | 16.00 | 25.76 | 33.61 | ||

| 湍流 | 7.19 | 24.37 | 32.09 | 37.76 | 43.05 | |

密封端面热力总倾 斜度Δψtf/10 | 层流 | 12.69 | 20.98 | 28.36 | ||

| 湍流 | 8.05 | 19.29 | 25.34 | 30.67 | 35.75 | |

表5 层流、湍流模型中密封端面倾斜度随进口温度的变化

Tab.5 The variation of sealing end face inclination with inlet temperature in laminar and turbulent flow models

| 进口温度To/K | 340 | 380 | 420 | 460 | 500 | |

|---|---|---|---|---|---|---|

静环端面力致倾 斜度Δψf/10 | 层流 | |||||

| 湍流 | ||||||

动环端面力致倾 斜度Δψf/10 | 层流 | 8.46 | 8.44 | 8.44 | 8.44 | 8.44 |

| 湍流 | 8.50 | 8.44 | 8.43 | 8.42 | 8.43 | |

密封端面力致倾 斜度Δψf/10 | 层流 | 0.94 | ||||

| 湍流 | 0.86 | |||||

静环端面热致倾 斜度Δψt/10 | 层流 | 10.09 | 16.14 | 20.94 | ||

| 湍流 | 5.11 | 15.90 | 20.33 | 23.56 | 26.69 | |

动环端面热致倾 斜度Δψt/10 | 层流 | 0.08 | 5.91 | 9.62 | 12.68 | |

| 湍流 | 2.08 | 8.47 | 11.76 | 14.20 | 16.35 | |

密封端面热致倾 斜度Δψt/10 | 层流 | 16.00 | 25.76 | 33.61 | ||

| 湍流 | 7.19 | 24.37 | 32.09 | 37.76 | 43.05 | |

密封端面热力总倾 斜度Δψtf/10 | 层流 | 12.69 | 20.98 | 28.36 | ||

| 湍流 | 8.05 | 19.29 | 25.34 | 30.67 | 35.75 | |

| [1] | 章聪. 兆瓦级超临界CO2透平与压缩机干气密封湍流效应与相变规律研究[D]. 杭州: 浙江工业大学, 2022. |

| ZHANG Cong. Turbulence Effect and Phase Change in Dry Gas Seals for MW-Scale Supercritical CO2 Turbines and Compressors[D]. Hangzhou: Zhejiang University of Technology, 2022. | |

| [2] | 沈伟, 彭旭东, 江锦波, 等. 高速超临界二氧化碳干气密封实际效应影响分析[J].化工学报, 2019, 70(7): 2645-2659. |

| SHEN Wei, PENG Xudong, JIANG Jinbo, et al. Analysis on Real Effect of Supercritical Carbon Dioxide Dry Gas Seal at High Speed[J]. CIESC Journal, 2019, 70(7): 2645-2659. | |

| [3] | 严如奇, 丁雪兴, 徐洁, 等. 基于湍流模型的S-CO2干气密封流场与稳态性能分析[J]. 化工学报, 2021, 72(8): 4292-4303. |

| YAN Ruqi, DING Xuexing, XU Jie, et al. Flow Field and Steady Performance of Supercritical Carbon Dioxide Dry Gas Seal Based on Turbulence Model[J]. CIESC Journal, 2021, 72(8): 4292-4303. | |

| [4] | FAIRUZ Z M, JAHN I, ABDUL-RAHMAN R. The Effect of Convection Area on the Deformation of Dry Gas Seal Operating with Supercritical CO2 [J]. Tribology International, 2019, 137: 349-365. |

| [5] | 徐洁, 俞树荣, 严如奇, 等. 超临界二氧化碳干气密封热-流-固耦合建模与变形特性分析[J]. 润滑与密封, 2021, 46(6): 1-9. |

| XU Jie, YU Shurong, YAN Ruqi, et al. Modeling and Deformation Characteristic Analysis of Thermal-Fluid-Solid Coupling of Supercritical Carbon Dioxide Dry Gas Seal[J]. Lubrication Engineering, 2021, 46(6): 1-9. | |

| [6] | 江鹏. 超临界CO2动静压干气密封稳态性能及热力变形特性研究[D]. 杭州: 浙江工业大学, 2022. |

| JIANG Peng. Study on Steady-State Performance and Thermal Deformation Characteristics of Supercritical CO2 Hydrodynamic-Static Hybrid Dry Gas Seal[D]. Hangzhou: Zhejiang University of Technology, 2022. | |

| [7] | 严如奇. 超临界二氧化碳干气密封流体动力润滑与密封性能研究[D]. 兰州: 兰州理工大学, 2022. |

| YAN Ruqi. The Research on Hydrodynamic Lubrication and Sealing Performance of Supercritical Carbon Dioxide Dry Gas Seal[D]. Lanzhou: Lanzhou University of Technology, 2022. | |

| [8] | WANG Zengli, WANG Qingyang, HAO Muming, et al. The Effect of Thermal-Elastic Deformation on the Sealing Performance of Supercritical CO2 Dry Gas Seal[J]. Industrial Lubrication and Tribology, 2023, 75(8): 950-958. |

| [9] | 王珺瑶, 张月, 邓帅, 等. CO2混合物热物性在CCS研究中的作用: 实验数据、理论模型和典型应用[J]. 化工进展, 2019, 38(3): 1244-1258. |

| WANG Junyao, ZHANG Yue, DENG Shuai, et al. Role of Thermodynamic Properties of CO2 Mixtures in CCS: Data, Models and Typical Applications[J]. Chemical Industry and Engineering Progress, 2019, 38(3): 1244-1258. | |

| [10] | 陈维, 宋鹏云, 许恒杰, 等. 含杂质CO2干气密封运行工况点物性参数计算及密封温度场分析[J]. 工程科学与技术, 2023, 55(1): 265-278. |

| CHEN Wei, SONG Pengyun, XU Hengjie, et al. Calculation of Physical Parameters and Analysis of Temperature Fields of CO2 with Impurities Dry Gas Seal at Operating Points[J]. Advanced Engineering Sciences, 2023, 55(1): 265-278. | |

| [11] | Wang J, Ryan D, Anthony E J, et al. The effect of impurities in oxyfuel flue gas on CO2 storage capacity[J]. International Journal of Greenhouse Gas Control, 2012, 11: 158-162. |

| [12] | GERNERT J, SPAN R. EOS-CG: a Helmholtz Energy Mixture Model for Humid Gases and CCS Mixtures[J]. Journal of Chemical Thermodynamics, 2016, 93: 274-293. |

| [13] | HIRS G G. A Bulk-Flow Theory for Turbulence in Lubricant Films[J]. Journal of Lubrication Technology, 1973, 95(2): 137-45. |

| [14] | 刘柯, 刘莹, 刘向峰. 端面流体动压密封中一种新的湍流计算模型[J]. 润滑与密封, 2006, (10): 110-112. |

| LIU Ke, LIU Ying, LIU Xiangfeng. New Turbulent Lubrication Model in Hydrodynamic Face Seal[J]. Lubrication Engineering, 2006, (10): 110-112. | |

| [15] | MIYAKE K, INOUE T, WATANABE Y. Two-Way Coupling Fluid–Structure Interaction Analysis and Tests of Shaft Vibration and Clearance Flow Across Plain Annular Seal[J]. Journal of Applied Mechanics, 2019, 86(10): 101002. |

| [16] | ZHANG C, JIANG J B, PENG X D, et al. The Influence and a Direct Judgement Method of the Flow State in Supercritical CO2 Dry Gas Seal[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2021, 43(11): 486. |

| [17] | 金杰. 高速螺旋槽端面机械密封的相变与稳定性研究[D]. 杭州: 浙江工业大学, 2021. |

| JIN Jie. Study on Phase Change and Stability of Spiral Groove Face Mechanical Seal at High Speed[D]. Hangzhou: Zhejiang University of Technology, 2021. | |

| [18] | 王勖成. 有限单元法[M]. 北京: 清华大学出版社, 2003: 36-63. |

| WANG Xucheng. Finite Element Method[M]. Beijing: Tsinghua University Press, 2003: 36-63. | |

| [19] | ZHANG C, JIANG J B, PENG X D, et al. An Investigation on Phase Transitions in a Supercritical CO2 Dry Gas Seal[J]. Tribology Transactions, 2022, 65(4): 728-748. |

| [20] | DU Q W, GAO K K, ZHANG D, et al. Effects of Grooved Ring Rotation and Working Fluid on the Performance of Dry Gas Seal[J]. International Journal of Heat and Mass Transfer, 2018, 126: 1323-1332. |

| [21] | 黄伟峰, 王伟达, 刘莹, 等. 氦气介质干气密封热-流固耦合建模及性能分析[J]. 润滑与密封, 2021, 46(2): 1-9. |

| HUANG Weifeng, WANG Weida, LIU Ying, et al. Thermal-fluid-solid Coupling Modeling and Performance Analysis of Dry Gas Seal for Helium Medium[J]. Lubrication Engineering, 2021, 46(2): 1-9. | |

| [22] | WANG H, ZHU B S, LIN J S, et al. A Thermohydrodynamic Analysis of Dry Gas Seals for High-Temperature Gas-Cooled Reactor[J]. Journal of Tribology, 2013, 135(2): 021701. |

| [1] | 李文倩, 刘战强, 赵金富, 王兵, 蔡玉奎. 干气密封动环表面的螺旋槽纳秒激光制备[J]. 中国机械工程, 2025, 36(10): 2207-2214. |

| [2] | 丁雪兴, 张伟政, 俞树荣, 韩明君, 杜兆年. 螺旋槽干气密封系统非线性动力学行为分析 [J]. 中国机械工程, 2010, 21(9): 1083-1087. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||