ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (10): 2292-2299.DOI: 10.3969/j.issn.1004-132X.2025.10.016

• 机械基础工程 • 上一篇

王星宇1( ), 郭岩宝1(

), 郭岩宝1( ), 张政1, 乔张宇1, 高发1, 陈金忠2, 刘畅2

), 张政1, 乔张宇1, 高发1, 陈金忠2, 刘畅2

收稿日期:2024-10-09

出版日期:2025-10-25

发布日期:2025-11-05

通讯作者:

郭岩宝

作者简介:王星宇,男,1997年生,博士研究生。研究方向为管道内检测器关键部件失效及补强机理。E-mail:w1786037396@163.com基金资助:

Xingyu WANG1( ), Yanbao GUO1(

), Yanbao GUO1( ), Zheng ZHANG1, Zhangyu QIAO1, Fa GAO1, Jinzhong CHEN2, Chang LIU2

), Zheng ZHANG1, Zhangyu QIAO1, Fa GAO1, Jinzhong CHEN2, Chang LIU2

Received:2024-10-09

Online:2025-10-25

Published:2025-11-05

Contact:

Yanbao GUO

摘要:

管道内检测器在经过管道缺陷时会加剧其密封盘的振动和疲劳损伤,影响检测可靠性并引发检测安全事故。借助ABAQUS软件研究了密封盘在管道内缺陷处的界面接触振动特性,重点探讨了接触振动的行为演化、衰减函数、疲劳脆弱点位置与疲劳寿命之间的内在联系。研究结果表明,密封盘经过管道缺陷时的振动过程包含碰撞、变形、近弹性和弹性4个阶段,其中弹性振动的动应力幅度呈指数衰减规律;总振动次数随管道缺陷深度和摩擦因数的增大而增大,且与疲劳寿命紧密相关;疲劳脆弱点集中在接触点和夹板边缘位置,与实际工况相符,验证了研究的准确性和可行性。

中图分类号:

王星宇, 郭岩宝, 张政, 乔张宇, 高发, 陈金忠, 刘畅. 管道内缺陷影响下的内检测器密封盘振动疲劳研究[J]. 中国机械工程, 2025, 36(10): 2292-2299.

Xingyu WANG, Yanbao GUO, Zheng ZHANG, Zhangyu QIAO, Fa GAO, Jinzhong CHEN, Chang LIU. Research on Vibration Fatigue of Pipeline Inspection Gauge Sealing Discs under Influences of Pipeline Defects[J]. China Mechanical Engineering, 2025, 36(10): 2292-2299.

| 部件 | 单元类型 | 单元数量 | 节点数量 |

|---|---|---|---|

| 夹板 | CAX4H;CAX3 | 509 | 553 |

| 直板 | CAX4H | 1124 | 1214 |

| 皮碗 | CAX4H | 780 | 848 |

| 管道 | CAX4H;CAX3 | 3669 | 3807 |

表1 仿真部件单元类型及节点数量

Tab.1 Element types and node numbers of simulation components

| 部件 | 单元类型 | 单元数量 | 节点数量 |

|---|---|---|---|

| 夹板 | CAX4H;CAX3 | 509 | 553 |

| 直板 | CAX4H | 1124 | 1214 |

| 皮碗 | CAX4H | 780 | 848 |

| 管道 | CAX4H;CAX3 | 3669 | 3807 |

| 材料 | 密度/(kg·m-3) | 弹性模量 /GPa | 泊松比 |

|---|---|---|---|

| 热塑性聚氨酯 | 1200 | ||

| 管道钢/夹板 | 7900 | 198.5 | 0.48 |

表2 力学性能参数

Tab.2 Material performance parameters

| 材料 | 密度/(kg·m-3) | 弹性模量 /GPa | 泊松比 |

|---|---|---|---|

| 热塑性聚氨酯 | 1200 | ||

| 管道钢/夹板 | 7900 | 198.5 | 0.48 |

| 参数 | μ1 | μ2 | μ3 | α1 | α2 | α3 | D1 | D2 | D3 |

|---|---|---|---|---|---|---|---|---|---|

| 值 | 36.27 | 8.58 | 0.08 | 8.04 | 0 | 0 | 0 |

表3 Ogden超弹性本构模型参数

Tab.3 Parameters of the Ogden hyperelastic constitutive Model

| 参数 | μ1 | μ2 | μ3 | α1 | α2 | α3 | D1 | D2 | D3 |

|---|---|---|---|---|---|---|---|---|---|

| 值 | 36.27 | 8.58 | 0.08 | 8.04 | 0 | 0 | 0 |

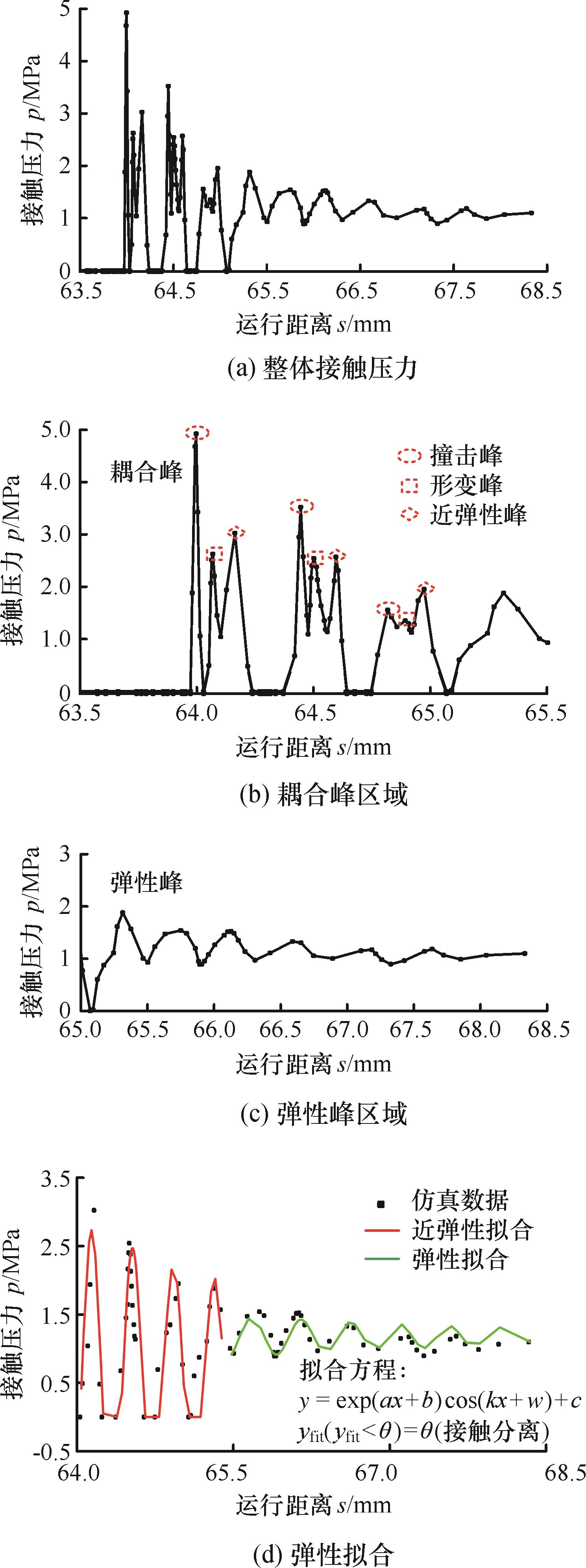

图4 直板在 μ =0.4、h=3.5 mm条件下经过管道缺陷时的接触压力振动拆解及拟合

Fig.4 Contact pressure vibration decomposition and fitting of the flat plate passing through pipeline defects under μ =4, h=3.5 mm conditions

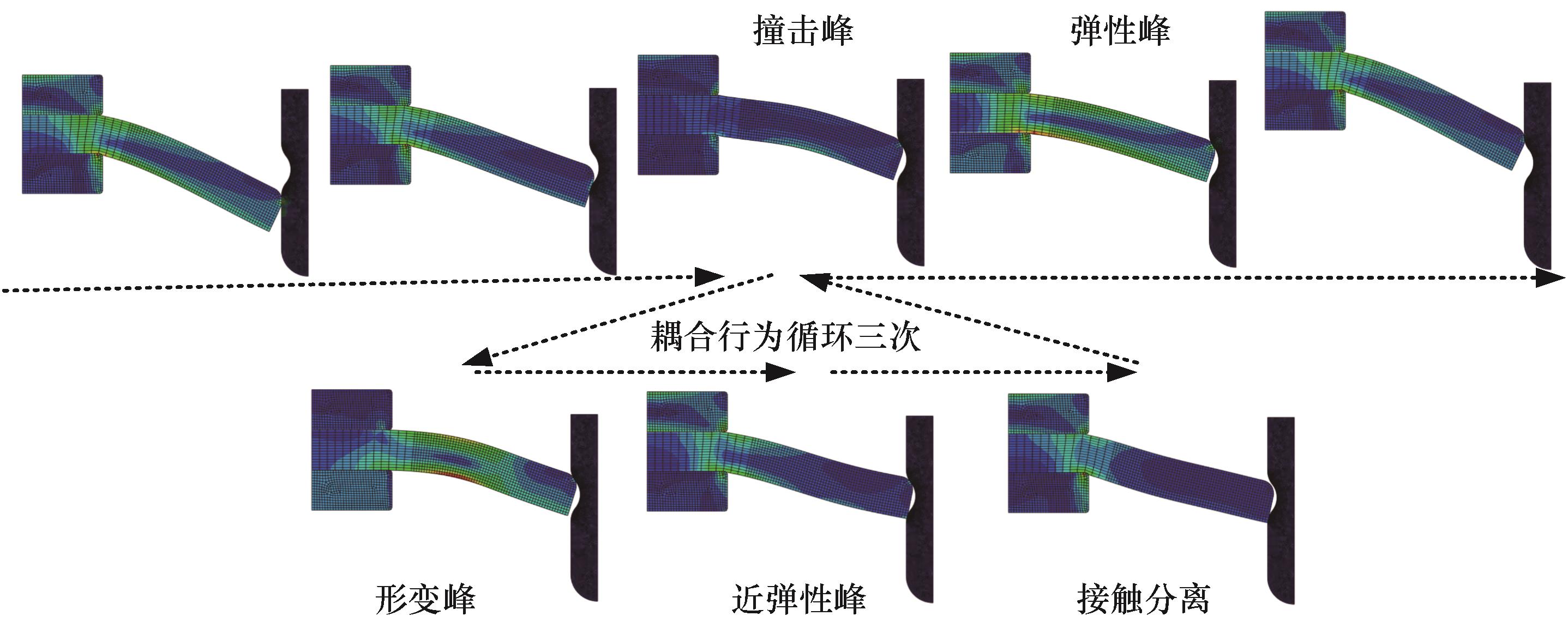

图5 直板在 μ =4、h=3.5 mm条件下经过管道缺陷时的振动行为演化过程

Fig.5 Evolution of vibration behavior for the flat plate passing through pipeline defects under μ =4, h=3.5 mm conditions

管道 缺陷 深度 h /mm | a | b | k | w | c | 拟合 优度R2 | 峰 谷 数 |

|---|---|---|---|---|---|---|---|

| 3.5 | 21.1 | 13.3 | 0 | 1.1769 | 0.639 | 15 | |

| 3.0 | 19.0 | 13.1 | 1.1222 | 0.776 | 8 | ||

| 2.5 | 19.1 | 13.2 | 1.2876 | 0.849 | 7 |

表4 直板经过不同管道缺陷深度的弹性拟合参数

Tab.4 Elastic fitting parameters of the flat plate traversing pipeline defects with varying depths

管道 缺陷 深度 h /mm | a | b | k | w | c | 拟合 优度R2 | 峰 谷 数 |

|---|---|---|---|---|---|---|---|

| 3.5 | 21.1 | 13.3 | 0 | 1.1769 | 0.639 | 15 | |

| 3.0 | 19.0 | 13.1 | 1.1222 | 0.776 | 8 | ||

| 2.5 | 19.1 | 13.2 | 1.2876 | 0.849 | 7 |

| [1] | MOHD Z A B, MOHD F M Y, SHEIKH A Z B S S, et al. Modeling of the In-pipe Inspection Robot:a Comprehensive Review[J]. Ocean Engineering, 2020, 203:107206. |

| [2] | 林俊明, 张开良, 林发炳, 等. 长输油气管道的无损检测 [J]. 无损检测, 2019, 41(9):44-47. |

| LIN Junming, ZHANG Kailiang, LIN Fabing, et al. Nondestructive Testing of Long-distance Oil and Gas Pipelines [J]. Nondestructive Testing, 2019, 41(9):44-47. | |

| [3] | 曹学文, 曹恒广, 赵湘阳, 等. 直板清管器与管壁间摩擦阻力的模拟研究[J]. 石油机械, 2021, 49(5):138-46. |

| CAO Xuewen, CAO Hengguang, ZHAO Xiangyang, et al. Simulation Study on the Friction Resistance between Straight Plate PIG and Pipeline Wall[J]. Petroleum Machinery, 2021, 49(5):138-146. | |

| [4] | 赵海旭, 樊建春. 皮碗式海洋管道内检测器通过性分析 [J]. 石油机械, 2021, 49(3):78-83. |

| ZHAO Haixu, FAN Jianchun. Passability Analysis of Cup-type In-line Inspection Tool for Offshore Pipelines [J]. Petroleum Machinery, 2021, 49(3):78-83. | |

| [5] | LIU C, WEI Y G, CAO Y G, et al. Traveling Ability of Pipeline Inspection Gauge (PIG) in Elbow under Different Friction Coefficients by 3D FEM [J]. Journal of Natural Gas Science and Engineering, 2020, 75:103134. |

| [6] | 李华, 王珂, 王东, 等. 天然气管道清管器自激振动模型及影响规律 [J]. 油气储运, 2018, 37(10):1163-9. |

| LI Hua, WANG Ke, WANG Dong, et al. Self-excited Vibration Model and Influence Laws of Gas Pipeline PIGs [J]. Oil & Gas Storage and Transportation, 2018, 37(10):1163-1169. | |

| [7] | 任涛, 郑吉霖, 曾威, 等. 冲击载荷下含腐蚀缺陷的海底管道损伤分析 [J]. 石油机械, 2024, 52(9):67-73. |

| REN Tao, ZHENG Jilin, ZENG Wei, et al. Damage Analysis of Subsea Pipeline with Corrosion Defects under Impact Load [J]. Petroleum Machinery, 2024, 52(9):67-73. | |

| [8] | TAN G B, WANG D G, LIU S H, et al. Probing Tribological Properties of Waxy Oil in Pipeline Pigging with Fluorescence Technique[J]. Tribology International, 2014, 71:26-37. |

| [9] | 刘猛, 刘文会, 温玉芬, 等. 国内埋地长输管道应力腐蚀开裂风险现状 [J]. 腐蚀与防护, 2022, 43(5):49-55. |

| LIU Meng, LIU Wenhui, WEN Yufen, et al. Current Status of Stress Corrosion Cracking Risk in Domestic Buried Long-distance Pipelines [J]. Corrosion and Protection, 2022, 43(5):49-55. | |

| [10] | 李睿, 郑健峰, 富宽, 等. 大口径管道投产前聚氨酯测径内检测器研制与应用 [J]. 油气储运, 2020, 39(6):638-44. |

| LI Rui, ZHENG Jianfeng, FU Kuan, et al. Development and Application of Polyurethane Diameter-measuring In-line Inspection Tool for Large-diameter Pipelines before Commissioning [J]. Oil & Gas Storage and Transportation, 2020, 39(6):638-644. | |

| [11] | ZHANG H, ZHANG S M, LIU S H, et al. Measurement and Analysis of Friction and Dynamic Characteristics of PIG's Sealing Disc Passing through Girth Weld in Oil and Gas Pipeline [J]. Measurement, 2015, 64:112-122. |

| [12] | LIU C, CAO Y G, TIAN H J, et al. A Novel Method for Analyzing the Driving Force of the Bi-directional PIG Based on the Four-element Model[J]. International Journal of Pressure Vessels and Piping, 2021, 190:104314. |

| [13] | WANG X Y, GUO Y B, ZHANG Z, et al. Study on the Dynamic Evolution of Friction and Wear of Polyurethane Material for Pipeline Inspection Gauge[J]. Proceedings of the Institution of Mechanical Engineers, Part J:Journal of Engineering Tribology, 2024, 238(12):1570-1582. |

| [14] | 刘超,罗传富.基于大变形疲劳理论的橡胶材料及制品疲劳寿命预测方法[J].高分子材料科学与工程,2024,40(7):103-111. |

| LIU Chao, LUO Chuanfu. Fatigue Life Prediction Method for Rubber Materials and Products Based on Large Deformation Fatigue Theory[J]. Polymer Materials Science and Engineering,2024,40(7):103-111. | |

| [15] | XU X Q, ZHOU X H, LIU Y Q. Fatigue Life Prediction of Rubber-sleeved Stud Shear Connectors under Shear Load Based on Finite Element Simulation [J]. Engineering Structures, 2021, 227:111449. |

| [16] | RIVLIN R S, THOMAS A G. Rupture of Rubber. I. Characteristic Energy for Tearing [J]. Journal of Polymer Science, 1953, 10(3):291-318. |

| [17] | LAKE G J, LINDLEY P B. The Mechanical Fatigue Limit for Rubber[J]. Journal of Applied Polymer Science, 1965, 9:1233-51. |

| [18] | LIU X N, SHANGGUAN W B, ZHAO X Z. Probabilistic Fatigue Life Prediction Model of Natural Rubber Components Based on the Expanded Sample Data[J]. International Journal of Fatigue, 2022, 163:107034. |

| [19] | FU H X, WANG Y, CHEN K, et al. A Fatigue Life Prediction Model of Flexible Spoke Non-pneumatic Tires[J]. Engineering Fracture Mechanics, 2024, 295:109795. |

| [1] | 程军圣, 袁毅, 喻镇涛, 袁辉. 考虑平均应力效应的Tovo-Benasciutti疲劳寿命预测模型[J]. 中国机械工程, 2015, 26(2): 196-199. |

| [2] | 崔泗鹏, 姚卫星, 夏天翔. 连接件振动疲劳寿命分析的名义应力法[J]. 中国机械工程, 2014, 25(18): 2519-2522. |

| [3] | 刘文光, 李俊, 严铖, 贺红林. 弹性梁损伤识别模态应变能法[J]. 中国机械工程, 2014, 25(12): 1651-1654. |

| [4] | 刘文光, 贺红林. 含裂纹板的振动疲劳裂纹扩展耦合分析[J]. 中国机械工程, 2012, 23(19): 2301-2305. |

| [5] | 高清振, 王耀华, 张晓南. 基于样本法的某型飞机救生机构振动疲劳寿命估算 [J]. 中国机械工程, 2011, 22(2): 162-165. |

| [6] | 刘文光, 陈国平. 呼吸式裂纹梁的振动疲劳裂纹扩展耦合分析 [J]. 中国机械工程, 2010, 21(23): 2798-2802. |

| [7] | 王明珠;姚卫星;孙伟;. 结构随机振动疲劳寿命估算的样本法[J]. J4, 2008, 19(8): 0-888,. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||