ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (10): 2171-2178.DOI: 10.3969/j.issn.1004-132X.2025.10.002

• 国家重点科技项目研究进展专栏 • 上一篇

收稿日期:2024-09-19

出版日期:2025-10-25

发布日期:2025-11-05

通讯作者:

向航

作者简介:王天奇,男,1999年生,助理工程师。研究方向为微型燃机叶片气动优化基金资助:

Tianqi WANG1, Jiang CHEN2, Hang XIANG2( ), Xiaofei SONG3

), Xiaofei SONG3

Received:2024-09-19

Online:2025-10-25

Published:2025-11-05

Contact:

Hang XIANG

摘要:

针对向心涡轮三维复杂叶片曲面气动优化过程中存在的几何调控难、控制变量多、寻优效率低等问题,基于直接操纵自由变形方法对向心涡轮流道和叶片多维度几何实施多自由度参数化,并引入预筛选代理模型辅助差分进化算法(Pre-SADE),结合python和流程自动化批处理脚本构建了数据驱动的向心涡轮全三维气动优化平台。对某向心涡轮开展流道-静/转叶片联合优化设计,结果表明,优化后向心涡轮导叶通道内马赫数明显降低,动静叶吸力面激波损失和分离损失减小,向心涡轮设计点绝热效率和流量分别提高了1.66%和1.7%,设计转速全工况效率特性均有所提升。该方法和平台在保证气动优化效果的同时,可有效减少优化变量和样本真实评估次数,显著改善寻优效率,满足向心涡轮快速、精细化优化设计需求。

中图分类号:

王天奇, 陈江, 向航, 宋晓飞. 基于预筛选代理模型和直接操纵自由变形参数化的向心涡轮气动优化[J]. 中国机械工程, 2025, 36(10): 2171-2178.

Tianqi WANG, Jiang CHEN, Hang XIANG, Xiaofei SONG. Aerodynamic Optimization of Radial Turbines Based on Surrogate Model of Pre-screened Strategies and DFFD Parameterization[J]. China Mechanical Engineering, 2025, 36(10): 2171-2178.

| 网格数目/104 | 流量/(kg·s-1) | 绝热效率 |

|---|---|---|

| 67 | 0.5027 | 0.8941 |

| 97 | 0.5055 | 0.9007 |

| 136 | 0.5054 | 0.9030 |

| 179 | 0.5054 | 0.9038 |

| 254 | 0.5054 | 0.9044 |

表1 网格无关性检验

Tab.1 Grid independence verification

| 网格数目/104 | 流量/(kg·s-1) | 绝热效率 |

|---|---|---|

| 67 | 0.5027 | 0.8941 |

| 97 | 0.5055 | 0.9007 |

| 136 | 0.5054 | 0.9030 |

| 179 | 0.5054 | 0.9038 |

| 254 | 0.5054 | 0.9044 |

| 压比 | 绝热效率 | 流量 | |

|---|---|---|---|

| 原始几何 | 3.6140 | 90.30% | 0.5054 kg·s |

| 优化后几何 | 3.6088 | 91.80% | 0.5142 kg·s |

| 相对差值 | +1.66% | +1.7% |

表2 设计点性能对比

Tab.2 Performance comparison at design point

| 压比 | 绝热效率 | 流量 | |

|---|---|---|---|

| 原始几何 | 3.6140 | 90.30% | 0.5054 kg·s |

| 优化后几何 | 3.6088 | 91.80% | 0.5142 kg·s |

| 相对差值 | +1.66% | +1.7% |

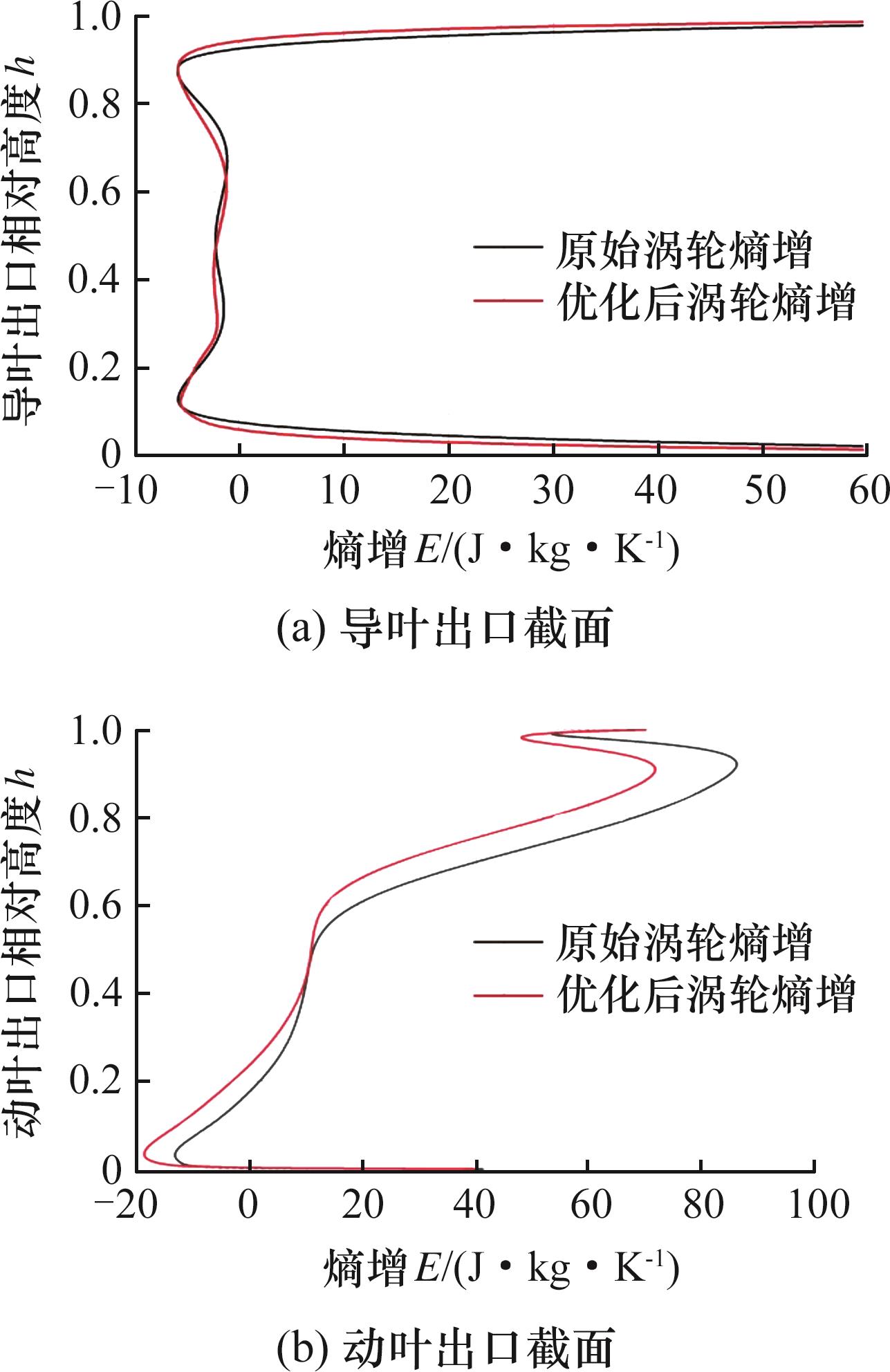

图16 优化前后导叶和动叶熵增在出口截面切向质量平均沿径向的分布曲线

Fig.16 Pre- and post-optimization radial distribution of circumferentially mass-averaged entropy rise at the stator vane and rotor blade exit plane

| [1] | WALSH P P, FLETCHER P. Gas Turbine Performance[M]. Malden, MA: Blackwell Science, 2004. |

| [2] | 陈明升,陈江,成金鑫,等.基于全叶片曲面参数化方法的涡轮气动优化[J].工程热物理学报,2023,44(3):641-653. |

| CHEN Mingsheng, CHEN Jiang, CHENG Jinxin, et al. Turbine Aerodvnamic Optimization Based on Total-blade Surface Parameterization Methoo[J]. Journal of Engineering Thermophysics, 2023, 44(3):641-653. | |

| [3] | LI Yan, XUE Songli, REN Xiaodong. Aerodynamic Optimization of a High-expansion Ratio Organic Radial-in-flow Turbine[J]. Journal of Mechanical Science and Technology,2016,30(12):5485-5490. |

| [4] | 杨伟平,欧阳玉清,房兴龙,等.基于iSIGHT的大膨胀比5.0级向心涡轮多目标优化与分析[J].推进技术,2022,43(9):79-89. |

| YANG Weiping, OUYANG Yuing, FANG Xinglong, et al. Multi-object Optimization and Analysis of 5.0 Expansion Ratio Radial Turbine Based on Isight[J]. Journal of Propulsion Technology, 2022, 43(9):79-89. | |

| [5] | LASSE M, ZUHEYR A, TOM V. Multidisciplinary Optimization of a Turbocharger Radial Turbine[J]. Journal of Turbomachinery, 2013,135(2):021022. |

| [6] | SONG P, SUN J, WANG K, et al. Development of an Optimization Design Method for Turbomachinery by Incorporating the Cooperative Coevolution Genetic Algorithm and Adaptive Approximate Model[C]∥Turbo Expo:Power for Land, Sea, and Air. Vancouver, British Columbia, Canada, 2011, 54679:1139-1153. |

| [7] | SEDERBERG T W, PARRY S R. Free-form Deformation of Solid Geometric Models[J]. ACM SIGGRAPH Computer Graphics, 1986, 20:151-160. |

| [8] | COQUILLART S. Extended Free-form Deformation:a Sculpturing Tool for 3D Geometric Modeling[J]. Proceedings of the 17th Annual Conference on Computer Graphics and Interactive Techniques, 1990, 20(4):187-196. |

| [9] | PREM K, ANGELO M, MAGNENAT T N, et al. Simulation of Facial Muscle Actions Based on Rational Free Form Deformations[J]. Computer Graphics Forum, 1992, 11(3):59-69. |

| [10] | LAMOUSIN H J, WAGGENSPACK W N. NURBS-based Free-form Deformations[J]. Computer Graphics&Applications IEEE, 1994, 14(6):59-65. |

| [11] | XIANG H, CHEN J. Aerothermodynamics Optimal Design of a Multistage Axial Compressor in a Gas Turbine Using Directly Manipulated Free-form Deformation[J]. Case Studies in Thermal Engineering, 2021, 26:101142. |

| [12] | 郭艺璇, 陈江, 刘熠, 等. 数据驱动的两级轴流涡轮多自由度气动优化设计[J].推进技术, 2024, 45(6):100-109. |

| GUO Yixuan, CHEN Jiang, LIU Yi, et al. Aerodvnamic Optimization Desian with Multiple Dearees of Freedom for a Two-stace Axial Turbine Based on Cata-driven[J]. Journal of Propulsion Technology, 2024, 45(6):100-109. | |

| [13] | LIU Y, CHEN J, CHENG J, et al. Aerodynamic Optimization of Transonic Rotor Using Radial Basis Function Based Deformation and Data-driven Differential Evolution Optimizer[J]. Aerospace, 2022, 9(9):508. |

| [14] | HU H, YU J, SONG Y, et al. The Application of Support Vector Regression and Mesh Deformation Technique in the Optimization of Transonic Compressor Design[J]. Aerospace Science and Technology, 2021, 112:106589 |

| [15] | 向航. 高负荷压气机气动设计与多型面整体优化探究[D]. 北京:北京航空航天大学, 2021. |

| XIANG Hang. Exploring Aerodynamic Design and Multi-surface Overall Optimization of Highly Loaded Compressor[D]. Beijing:Beihang University, 2021. | |

| [16] | 池元成, 方杰, 饶大林, 等. 自适应中心变异差分进化算法及其在涡轮叶型优化设计中的应用[J]. 航空动力学报, 2010, 25(8):1849-1854. |

| CHI Yuancheng, FANG Jie, RAO Dalin, et al. Self-adaptive Center-mutation Differential Evolution and Its Application to Shape Optimization Design of a Turbine Blade[J]. Journal of Aerospace Power, 2010, 25(8):1849-1854. | |

| [17] | KRIGE D G. A Statistical Approach to Some Basic Mine Valuation Problems on the Witwatersrand[J]. Journal of the Southern African Institute of Mining and Metallurgy, 1951, 52(6):119-139. |

| [18] | MATHERON G. Principles of Geostatistics[J]. Economic Geology, 1963, 58(8):1246-1266. |

| [19] | BUHMANN M D. Radial Basis Fimctions[J]. Acta numerica, 2000, 9:1-38 |

| [20] | 刘熠. 轴流压气机人工智能气动设计优化探索[D]. 北京:北京航空航天大学, 2023. |

| LIU Yi. Exploring Artificial Intelligence Assisted Aerodynamic Design and Optimization of Axial Compressor[D]. Beijing:Beihang University, 2023. | |

| [21] | CHENG J, YANG C, ZHAO S. A Phased Aerodynamic Optimization Method for Compressors Based on Multi-degrees-of-freedom Surface Parameterization[J]. Journal of Thermal Science, 2021, 30(6):2071-2086. |

| [1] | 安裕强, 张源, 邹平, 陶翼飞. 基于批次拆分机制的IMODE算法求解成品卷烟生产调度问题[J]. 中国机械工程, 2025, 36(8): 1893-1903. |

| [2] | 魏书鹏, 唐红涛, 李西兴, 杨冠宇, 张健. 考虑双资源约束的柔性机械加工车间逆调度问题研究[J]. 中国机械工程, 2024, 35(03): 457-471. |

| [3] | 张源, 陶翼飞, 王加冕. 改进差分进化算法求解混合流水车间调度问题[J]. 中国机械工程, 2021, 32(06): 714-720. |

| [4] | 刘元铭, 王振华, 王涛, 刘文礼, 熊晓燕. [成形质量的闭环与自适应控制技术]热轧带钢出口凸度数据驱动建模及智能化预测分析[J]. 中国机械工程, 2020, 31(22): 2728-2733. |

| [5] | 徐亚旋;刘梁;常思勤;胡茂杨. 电磁驱动配气机构的发动机分缸工作一致性控制[J]. 中国机械工程, 2019, 30(21): 2546-2553. |

| [6] | 孙浩, 肖宏, 胡庆军. 基于有约束多目标进化算法的冷轧负荷分配分析[J]. 中国机械工程, 2017, 28(01): 93-100. |

| [7] | 符纯明, 姜, 潮, 陈光宋, 吉磊. 基于隔代映射算子的差分进化算法[J]. 中国机械工程, 2016, 27(11): 1523-1529,1545. |

| [8] | 何改云, 刘欣, 刘佩佩, 郭龙真. 基于分割球面逼近和差分进化的复杂曲面轮廓度误差评定[J]. 中国机械工程, 2014, 25(2): 152-156. |

| [9] | 车林仙, 何兵, 程志红. 6-CRS并联机器人机构及其位置分析 [J]. 中国机械工程, 2010, 21(14): 1669-1675. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||