ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (11): 2757-2765.DOI: 10.3969/j.issn.1004-132X.2025.11.034

• 先进材料加工工程 • 上一篇

周潼1( ), 程军2, 王克鲁1(

), 程军2, 王克鲁1( ), 鲁世强1, 李鑫1, 刘杰1

), 鲁世强1, 李鑫1, 刘杰1

收稿日期:2024-12-23

出版日期:2025-11-25

发布日期:2025-12-09

通讯作者:

王克鲁

作者简介:周潼,2000年生,男,硕士研究生。研究方向为增材制造工艺参数优化。E-mail: 1826646458@qq.com基金资助:

Tong ZHOU1( ), Jun CHENG2, Kelu WANG1(

), Jun CHENG2, Kelu WANG1( ), Shiqiang LU1, Xin LI1, Jie LIU1

), Shiqiang LU1, Xin LI1, Jie LIU1

Received:2024-12-23

Online:2025-11-25

Published:2025-12-09

Contact:

Kelu WANG

摘要:

通过等温恒应变速率压缩试验,研究了Ti2AlNb基合金在650~850 ℃、应变速率0.001~1 s-1范围内的热变形行为,并基于动态材料模型理论构建了三维加工图。分析了Ti2AlNb基合金的流动应力曲线,建立了支持向量机本构模型,再对三维加工图进行了理论分析,最后结合微观组织验证了所构建三维加工图的准确性。研究结果表明,Ti2AlNb基合金的流动应力随变形温度的降低和应变速率的增加而增大;支持向量机模型能准确预测Ti2AlNb基合金在不同变形工艺参数下的流动行为,其相关系数为0.999,平均相对误差为0.67%;三维加工图表明,功率耗散效率η值较大的区域集中在低应变速率区域;不同应变下Ti2AlNb基合金较好的热变形工艺参数范围为675~725 ℃、0.001~0.003 s-1,最佳热变形工艺参数为700 ℃、0.001 s-1。

中图分类号:

周潼, 程军, 王克鲁, 鲁世强, 李鑫, 刘杰. Ti2AlNb基合金热变形行为及加工图研究[J]. 中国机械工程, 2025, 36(11): 2757-2765.

Tong ZHOU, Jun CHENG, Kelu WANG, Shiqiang LU, Xin LI, Jie LIU. Hot Deformation Behavior and Processing Maps of Ti2AlNb-based Alloys[J]. China Mechanical Engineering, 2025, 36(11): 2757-2765.

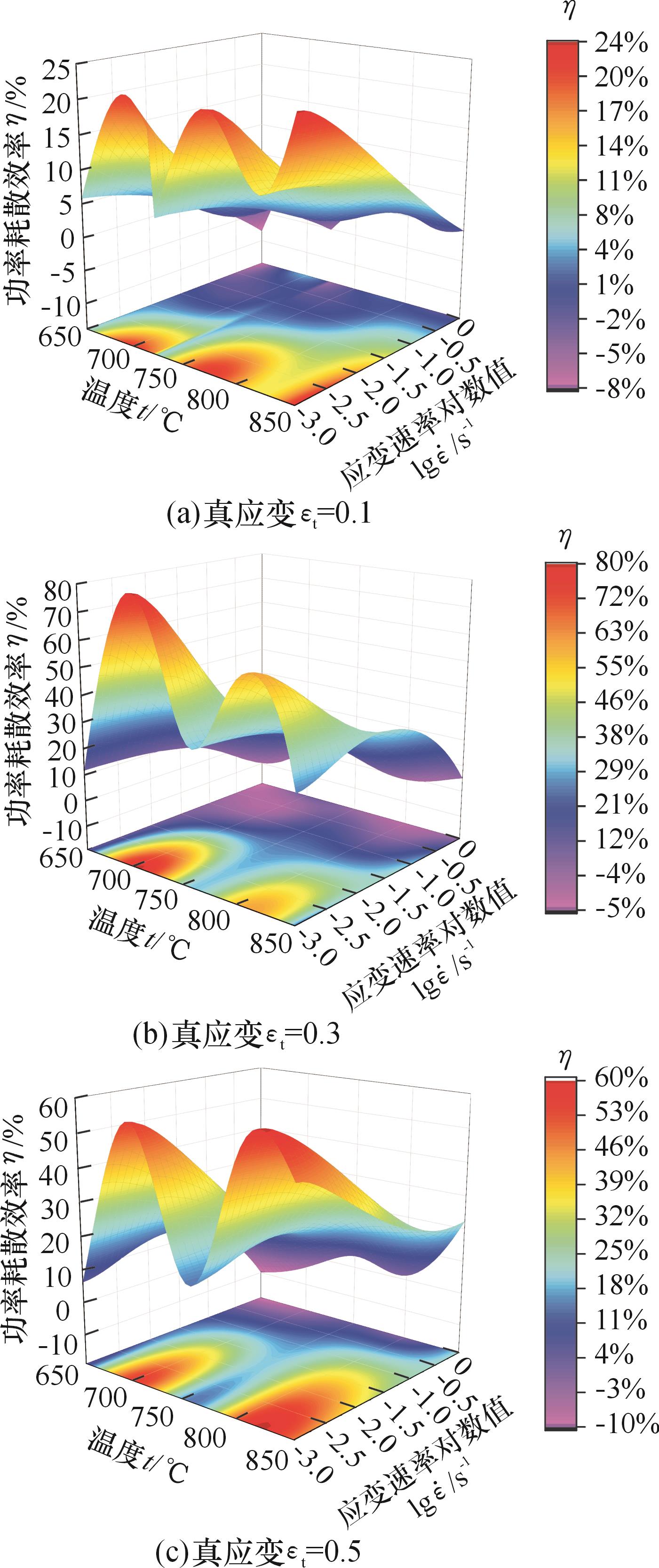

图5 不同应变下Ti2AlNb基合金的功率耗散效率三维分布图

Fig.5 Three-dimensional distribution diagram of power dissipation efficiency for Ti2AlNb-based alloy under different strains

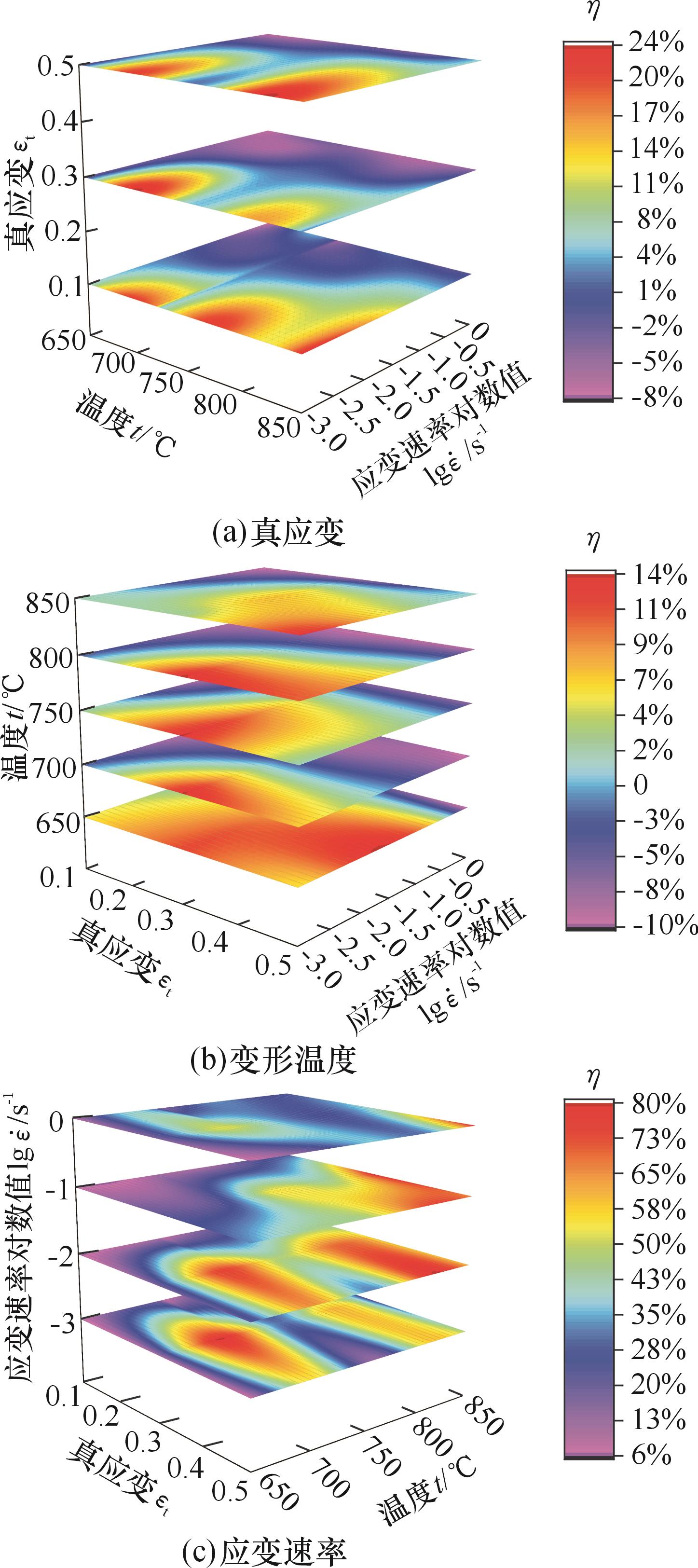

图6 不同工艺参数下Ti2AlNb基合金的功率耗散效率三维分布图

Fig.6 Three-dimensional distribution diagram of power dissipation efficiency for Ti2AlNb-based alloys under different processing parameters

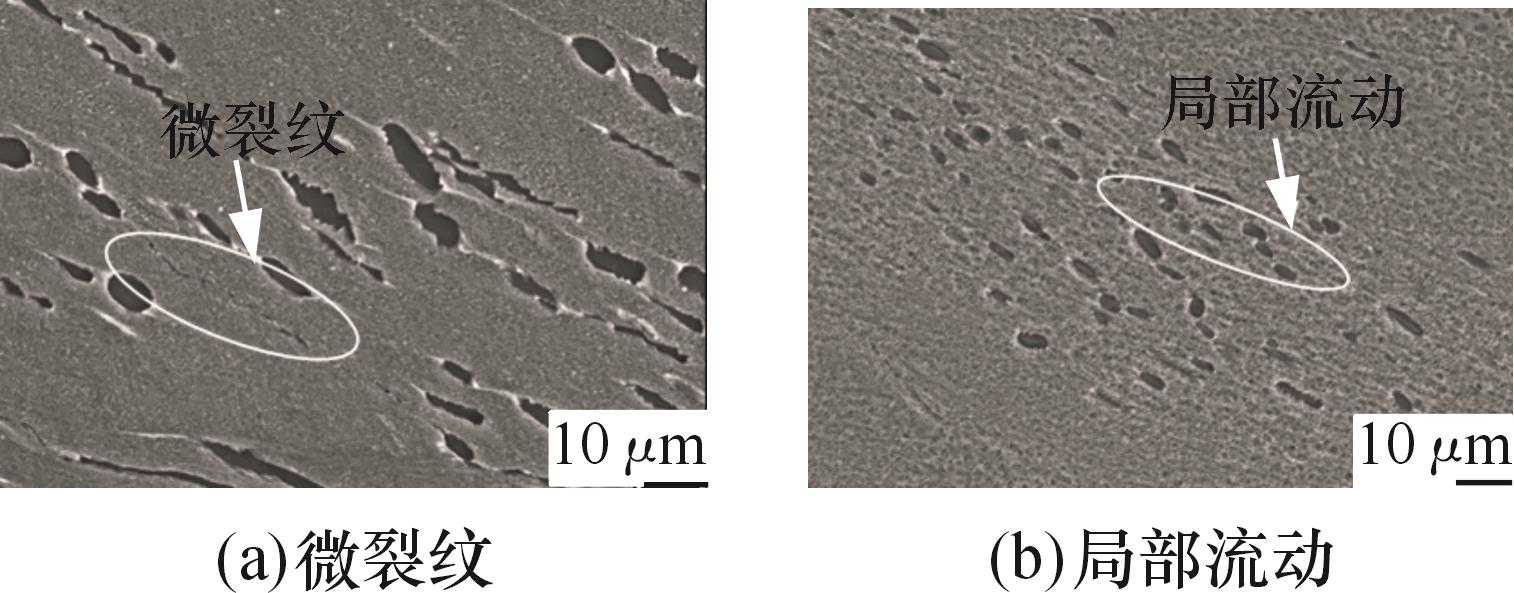

图10 应变0.5、应变速率1 s-1、变形温度650 ℃下的失稳变形微观组织

Fig.10 Microstructure of the instability deformation under true strain of 0.5,strain rate of 1 s-1,deformation temperature of 650 ℃

| [1] | PENG Zhenlong, ZHANG Xiangyu, LIU Liangbao, et al. Effect of High-speed Ultrasonic Vibration Cutting on the Microstructure, Surface Integrity, and Wear Behavior of Titanium Alloy[J]. Journal of Materials Research and Technology 2023, 24: 3807-3888. |

| [2] | 曹子文, 朱明, 浦智能, 等. 烧结温度对Ti2AlNb合金显微组织及高温拉伸性能的影响[J]. 材料热处理学报, 2024, 45(8): 77-84. |

| CAO Ziwen, ZHU Ming, PU Zhineng, et al. Effect of Sintering Temperature on Microstructure and High Temperature Tensile Properties of Ti2AlNb Alloy[J]. Transactions of Materials and Heat Treatment,2024, 45(8): 77-84. | |

| [3] | 陈金坤, 姜凤阳, 思芳, 等. 二次烧结温度对放电等离子烧结制备Ti2AlNb合金显微组织和力学性能的影响[J]. 稀有金属与硬质合金, 2024, 52(4):54-58. |

| CEHN Jinkun, JIANG Fengyang, SI Fang, et al. Effect of Second-sintering Temperature on Microstructure and Mechanical Properties of Ti2AlNb Prepared by Spark Plasma Sintering[J]. Rare Metals and Cemented Carbides, 2024, 52(4):54-58. | |

| [4] | 马秀萍, 卜志强, 李然, 等. Ti2AlNb合金热模拟焊接热影响区的组织与力学性能[J]. 材料热处理学报, 2024, 45(2): 204-210. |

| MA Xiuping, PU Zhiqiang, LI Ran, et al. Microstructure and Mechanical Properties of Thermal Simulation Welding Heat-affected Zone of Ti2AlNb Alloy[J]. Transactions of Materials and Heat Treatment, 2024, 45(2): 204-210. | |

| [5] | 冯艾寒, 陈强, 王剑, 等. 低密度Ti2AlNb基合金热轧板微观组织的热稳定性[J]. 金属学报, 2023, 59(6): 777-786. |

| FENG Aihan, CHEN Qiang, WANG Jian, et al. Thermal Stability of Microstructures in Low-density Ti2AlNb-based Alloy Hot Rolled Plate[J]. Acta Metallurgica Sinica, 2023, 59(6): 777-786. | |

| [6] | 吴良, 陈铮. 基于支持向量机的材料热处理性能预测模型研究[J]. 材料热处理学报, 2007, 59(6): 152-155. |

| WU Liang, CHEN Zheng. Study on SVM Based Mathematical Model Used to Predict Mechanical Properties of Materials after Heat Treatment[J]. Transactions of Materials and Heat Treatment, 2007, 59(6): 152-155. | |

| [7] | LIU Limeng, CHU Maoxiang, GONG Rongfeng, et al. Unbalanced Classification Method Using Least Squares Support Vector Machine with Sparse Strategy for Steel Surface Defects with Label Noise[J]. Journal of Iron and Steel Research International, 2020, 27: 1407-1419. |

| [8] | 尹晓珊, 钟建琳, 彭宝营, 等. 基于麻雀算法优化的最小二乘支持向量机Ti2AlNb切削力预测研究[J]. 工具技术, 2023, 57(10): 63-68. |

| YIN Xiaoshan, ZHONG Jianlin, PENG Baoying,et al. Prediction of Ti2AlNb Cutting Force Based on Sparrow Algorithm Optimized Least Squares Support Vector Machine[J]. Tool Engineering, 2023, 57(10): 63-68. | |

| [9] | SIM K H, RI Y C, JO C H, et al. Modified Zerilli-Armstrong and Khan-Huang-Liang Constitutive Models to Predict Hot Deformation Behavior in a Powder Metallurgy Ti-22Al-25Nb Alloy[J].Vacuum, 2023, 210: 111749. |

| [10] | CHAI Yunpeng, ZHU Yanchun, QIN Ling, et al. High-temperature Hot Deformation Behavior and Processing Map of Ti-22Al-25Nb Alloy[J]. Materials Today Communications, 2024, 41: 110599. |

| [11] | PRASAD Y V R K, GEGEL H L, DORAIVELU S M, et al. Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242[J]. Metallurgical Transactions A,1984, 15(10): 1883-1892. |

| [12] | 刘晓燕, 张习祎, 陈秀全, 等. 热挤压态FGH96合金热变形行为及变形机制研究[J]. 稀有金属, 2024, 48(8): 1108-1119. |

| LIU Xiaoyan, ZHANG Xiwei, CHEN Xiuquan, et al. Hot Deformation Behavior and Deformation Mechanism of Hot Extruded FGH96 Superalloy[J]. Chinese Journal of Rare Metals, 2024, 48(8): 1108-1119. | |

| [13] | LI Chunhong, QIU Risheng, LUAN Baifeng, et al. Hot Deformation and Processing Maps of As-sintered CNT/Al-Cu Composites Fabricated by Flake Powder Metallurgy[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(9): 1695-1704. |

| [14] | 周伟, 管峰涛, 钱新安, 等. 人工神经网络算法在粗晶Ti2AlNb合金本构关系模型建立中的应用[J]. 热加工工艺, 2023, 52(22): 107-109. |

| ZHOU Wei, GUAN Fengtao, QIAN Xin'an, et al. Application of Artificial Neural Network in Establishment of Constitutive Relationship Model of Coarse Grained Ti2AlNb[J]. Hot Working Technology, 2023, 52(22): 107-109. | |

| [15] | LIANG Shengli, ZHOU Meng, ZHANG Yi, et al. Thermal Deformation Behavior of GO/CeO2 In-situ Reinforced Cu30Cr10W Electrical Contact Material[J]. Journal of Alloys and Compounds, 2022, 899: 163266. |

| [16] | RANJAN A, MAHARAJA H, MISHRA S, et al. Microstructural Effects and Constitutive Modelling of Cyclic Softening Behaviour in Ti-6Al-4V Titanium Alloys[J]. Materials Science and Engineering A, 2024, 901: 146527. |

| [17] | 张志雄, 章俊涛, 韩建超, 等. 马氏体组织Ti-6Al-4V钛合金多向等温锻造组织演变及力学性能强化研究[J]. 中国机械工程, 2021, 32(22): 2739-2748. |

| ZHANG Zhixiong, ZHANG Juntao, HAN Jian-chao, et al. Microstructure and Mechanics Property Variations Duringmdlf of Ti-6Al-4V Alloy with a Martensitic Microstructure[J]. China Mechanical Engineering, 2021, 32(22): 2739-2748. | |

| [18] | GAO Wei, XU Fan, ZHOU Zhihua. Towards Convergence Rate Analysis of Random Forests for Classification[J]. Artificial Intelligence, 2022, 313: 103788. |

| [19] | ZHANG Tong. Statistical Behavior and Consistency of Classification Methods Based on Convex Risk Minimization[J]. The Annals of Statistics, 2004, 32(1): 56-85. |

| [20] | 李航. 统计学习方法[M]. 北京: 清华大学出版社, 2012. |

| LI Hang. Statistical Learning Method[M]. Beijing: Tsinghua University Press, 2012. | |

| [21] | TAKHANOV R. On the Speed of Uniform Convergence in Mercer's Theorem[J]. Journal of Mathematical Analysis and Applications, 2023, 518(2): 126718. |

| [22] | PAN Binbin, LAI Jianhuang, CHEN Wensheng. Nonlinear Nonnegative Matrix Factorization Based on Mercer Kernel Construction[J]. Pattern Recognition, 2011, 44(10/11): 2800-2810. |

| [23] | SUYKENS J A K, VANDEWALLE J. Least Squares Support Vector Machine Classifiers[J]. Neural Processing Letters, 1999, 9: 293-300. |

| [24] | WEN D X, LIN Y C, LI H B, et al. Hot Deformation Behavior and Processing Map of a Typical Ni-based Superalloy[J]. Materials Science and Engineering A, 2014, 591: 183-192. |

| [25] | MURTY S V S. N, RAO B N. On the Development of Instability Criteria during Hotworking with Reference to IN 718 [J]. Materials Science and Engineering: A, 1998, 254(1/2): 76-82. |

| [26] | DONG Xuemao, XU Jing, FENG Zhongxue, et al. Exploring Hot Deformation Behavior of the Solutionized Cu-15Ni-8Sn Alloy through Constitutive Equations and Processing Maps[J]. Journal of Materials Research and Technology, 2024, 29: 2142-2153. |

| [27] | 姜森宝, 王宇盛, 陈瑶, 等. Ti2AlNb钛合金轧板激光弯曲工艺及微观组织[J]. 锻压技术, 2024, 49(5): 61-66. |

| JIANG Senbao, WANG Yusheng, CHEN Yao, et al. Laser Bending Process and Microstructure for Ti2AlNb Titanium Alloy Rolled Sheet[J]. Forging & Stamping Technology, 2024, 49(5): 61-66. | |

| [28] | WU Ronghai, LIU Yang, GENG Cong, et al. Study on Hot Deformation Behavior and Intrinsic Workability of 6063 Aluminum Alloys Using 3D Processing Map[J]. Journal of Alloys and Compounds, 2017, 713: 212-221. |

| [29] | KONG Yonghua, CHANG Pengpeng, LI Qian, et al. Hot Deformation Characteristics and Processing Map of Nickel-based C276 Superalloy[J]. Journal of Alloys and Compounds, 2015, 622: 738-744. |

| [30] | LI Chunxiao, JIN Jianfeng, YAN Hong, et al. Investigation of Hot Deformation Behavior of Mg-14Gd-0.5 Zr (wt%) through Constitutive Analysis and Processing Maps[J]. Journal of Alloys and Compounds, 2023, 953: 170112. |

| [31] | 蔡述巧, 王勇帆, 陈克鑫, 等. 18Cr2Ni4W钢的热变形行为及热加工图[J]. 材料热处理学报, 2024, 45(7): 201-211. |

| CAI Shuqiao, WANG Yongfan, CHEN Kexin, et al. Hot Deformation Behavior and Hot Processing Map of 18Cr2Ni4W Steel[J]. Transactions of Materials and Heat Treatment, 2024,45(7): 201-211. | |

| [32] | 王斌, 张凯锋, 蒋少松, 等. 固溶温度对Ti2AlNb基合金组织演变的影响[J]. 航空材料学报, 2015, 35(3): 7-12. |

| WANG Bin, ZHANG Kaifeng, JIANG Shaosong, et al. Effect of Solution Treatment Temperature on Microstructural Evolution of Ti2AlNb-based Alloy[J]. Journal of Aeronautical Materials, 2015, 35(3): 7-12. |

| [1] | 吴石, 张勇, 王宇鹏, 王春风. 基于双信号融合的主轴/刀柄结合面刚度退化程度预测[J]. 中国机械工程, 2024, 35(08): 1449-1461. |

| [2] | 岳建锋, 龙新宇, 黄云龙, 郭嘉龙, 刘文吉. 基于电弧声信号的窄间隙脉冲熔化极气体保护焊侧壁熔合状态在线识别[J]. 中国机械工程, 2024, 35(02): 244-250,259. |

| [3] | 胡博, 罗炜韬, 王少飞, 蓝希旺. 基于支持向量机参数优化的高温合金表面缺陷磁异常定量研究[J]. 中国机械工程, 2023, 34(17): 2058-2064. |

| [4] | 李向杰, 张向文, . 基于人工蜂群支持向量机的电动汽车制动意图识别方法[J]. 中国机械工程, 2021, 32(17): 2125-2135. |

| [5] | 丁嘉鑫;王振亚;姚立纲;蔡永武. 广义复合多尺度加权排列熵与参数优化支持向量机的滚动轴承故障诊断[J]. 中国机械工程, 2021, 32(02): 147-155. |

| [6] | 刘元铭, 王振华, 王涛, 刘文礼, 熊晓燕. [成形质量的闭环与自适应控制技术]热轧带钢出口凸度数据驱动建模及智能化预测分析[J]. 中国机械工程, 2020, 31(22): 2728-2733. |

| [7] | 余杭卓1;秦圣峰1,2;丁国富1;江磊1;梁红琴1. 侧铣加工刀具回转轮廓误差预测技术研究[J]. 中国机械工程, 2020, 31(03): 306-313. |

| [8] | 王福斌1;潘兴辰1;孙宇舸2;郭宝军3. 钢坯拉速模糊信息粒化及钢坯定重切割的极限学习机预报[J]. 中国机械工程, 2019, 30(24): 2968-2973. |

| [9] | 宁静;冉伟;种传杰;陈春俊. 基于S变换的高速列车小幅蛇行识别方法[J]. 中国机械工程, 2019, 30(09): 1097-1102,1110. |

| [10] | 何刘海;吴桂娇;王平. 基于支持向量机决策树的航空发动机轴心轨迹识别方法[J]. 中国机械工程, 2019, 30(08): 969-974. |

| [11] | 王福斌1, 2;孙海洋1;TU Paul2. 边缘扩展的皮带撕裂支持向量机视觉检测[J]. 中国机械工程, 2019, 30(04): 455-460. |

| [12] | 唐秋华1,2,3;成丽新1,2,3;张利平1,2,3. 扰动累积下基于机器学习的重调度方式选择[J]. 中国机械工程, 2019, 30(04): 472-479. |

| [13] | 葛亮, 苗瑞, 葛秋原, 吴易洲. [质量优化]窄搭接焊缝涡流信号的特征提取与缺陷识别[J]. 中国机械工程, 2019, 30(02): 225-229. |

| [14] | 张旭刚, 敖秀奕, 张华, 江志刚, . [机械装备再制造]考虑失效特征的废旧零部件再制造成本预测模型研究[J]. 中国机械工程, 2018, 29(21): 2594-2599. |

| [15] | 石琴, 仇多洋, 吴冰, 李一鸣, 刘炳姣. [智能感知]基于粒子群优化支持向量机算法的行驶工况识别及应用[J]. 中国机械工程, 2018, 29(15): 1875-1883. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||