ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (10): 2343-2350.DOI: 10.3969/j.issn.1004-132X.2025.10.023

• 可持续制造 • 上一篇

郭保苏1,2( ), 王永春1, 马健明1, 孙万诚1, 王世运1, 黄传真1,2(

), 王永春1, 马健明1, 孙万诚1, 王世运1, 黄传真1,2( )

)

收稿日期:2024-12-06

出版日期:2025-10-25

发布日期:2025-11-05

通讯作者:

黄传真

作者简介:郭保苏,男,1986年生,教授、博士研究生导师。研究方向为智能排样、故障诊断、精密与超精密加工。E-mail:guobaosu@ysu.edu.cn基金资助:

Baosu GUO1,2( ), Yongchun WANG1, Jianming MA1, Wancheng SUN1, Shiyun WANG1, Chuanzhen HUANG1,2(

), Yongchun WANG1, Jianming MA1, Wancheng SUN1, Shiyun WANG1, Chuanzhen HUANG1,2( )

)

Received:2024-12-06

Online:2025-10-25

Published:2025-11-05

Contact:

Chuanzhen HUANG

摘要:

为了解决大理石板的下料问题,确保成品矩形板材的纹理和色差一致,同时提高材料的利用率,采取轮廓提取算法对大理石母板可排样区域进行轮廓提取,提出了基于母板滑动策略的矩形件排样方法。采用齐头切约束下的最低水平线算法构建样件域,提出融合人工蜂群算法和黑寡妇算法的混合算法(ABWO)对样件域进行优化。通过母板在样件域中进行滑动与旋转寻优,以母板填充率作为评价指标,实现了最优排样方案的高效求解。实验结果表明:在单一规格矩形的排样实验中,所提方法排样时间缩短90%以上,排样填充率与传统方法相当,排样结果满足一刀切约束,有利于后续切割下料;非单一规格矩形排样实验中,采用ABWO算法对零件排入顺序进行优化,样件域填充率提高5%。结合母板滑动策略,最终排样填充率与传统排样方法相比提高了3%。

中图分类号:

郭保苏, 王永春, 马健明, 孙万诚, 王世运, 黄传真. 基于母板滑动策略的大理石板材排样算法[J]. 中国机械工程, 2025, 36(10): 2343-2350.

Baosu GUO, Yongchun WANG, Jianming MA, Wancheng SUN, Shiyun WANG, Chuanzhen HUANG. A Method for Packing Marble Slabs Based on Original Plate Sliding Strategy[J]. China Mechanical Engineering, 2025, 36(10): 2343-2350.

| No. | 传统排样方法 | 本文方法 | ||

|---|---|---|---|---|

| 排入数量 | 运行时间/s | 排入数量 | 运行时间/s | |

| 1 | 56 | 10.211 | 54 | 0.159 |

| 2 | 20 | 2.022 | 20 | 0.149 |

| 3 | 28 | 3.411 | 26 | 0.099 |

| 4 | 29 | 1.252 | 29 | 0.092 |

| 5 | 29 | 4.429 | 28 | 0.096 |

| 6 | 42 | 9.774 | 41 | 0.151 |

| 7 | 32 | 7.841 | 30 | 0.098 |

| 8 | 46 | 23.234 | 46 | 0.113 |

| 9 | 105 | 44.236 | 113 | 0.201 |

表1 本文方法与传统排样方法的对比结果

Tab.1 The results of comparison between the proposed method and the traditional layout method

| No. | 传统排样方法 | 本文方法 | ||

|---|---|---|---|---|

| 排入数量 | 运行时间/s | 排入数量 | 运行时间/s | |

| 1 | 56 | 10.211 | 54 | 0.159 |

| 2 | 20 | 2.022 | 20 | 0.149 |

| 3 | 28 | 3.411 | 26 | 0.099 |

| 4 | 29 | 1.252 | 29 | 0.092 |

| 5 | 29 | 4.429 | 28 | 0.096 |

| 6 | 42 | 9.774 | 41 | 0.151 |

| 7 | 32 | 7.841 | 30 | 0.098 |

| 8 | 46 | 23.234 | 46 | 0.113 |

| 9 | 105 | 44.236 | 113 | 0.201 |

| 算法 | 编号 | 利用率 | 平均利用率 |

|---|---|---|---|

| Tabu | (1) | 87.372 | 87.616 |

| (2) | 87.685 | ||

| (3) | 87.790 | ||

| ABC | (1) | 87.592 | 88.189 |

| (2) | 88.328 | ||

| (3) | 88.648 | ||

| BWO | (1) | 88.482 | 88.899 |

| (2) | 89.006 | ||

| (3) | 89.209 | ||

| ABWO | (1) | 93.719 | 93.839 |

| (2) | 93.852 | ||

| (3) | 93.945 |

表2 4种启发式算法对样件域的布局优化结果 (%)

Tab.2 The layout optimization results of part domain by 4 heuristic algorithms

| 算法 | 编号 | 利用率 | 平均利用率 |

|---|---|---|---|

| Tabu | (1) | 87.372 | 87.616 |

| (2) | 87.685 | ||

| (3) | 87.790 | ||

| ABC | (1) | 87.592 | 88.189 |

| (2) | 88.328 | ||

| (3) | 88.648 | ||

| BWO | (1) | 88.482 | 88.899 |

| (2) | 89.006 | ||

| (3) | 89.209 | ||

| ABWO | (1) | 93.719 | 93.839 |

| (2) | 93.852 | ||

| (3) | 93.945 |

| 母板 | 填充率/% | |||

|---|---|---|---|---|

| 传统排样方法 | ABC | BWO | ABWO | |

| A | 88.33 | 88.31 | 85.07 | 91.85 |

| B | 90.43 | 89.28 | 84.79 | 93.63 |

表3 不同顺序优化算法下非单一规格矩形排样填充率

Tab.3 Filling rate of non-single rectangular layout under different sequential optimization algorithms

| 母板 | 填充率/% | |||

|---|---|---|---|---|

| 传统排样方法 | ABC | BWO | ABWO | |

| A | 88.33 | 88.31 | 85.07 | 91.85 |

| B | 90.43 | 89.28 | 84.79 | 93.63 |

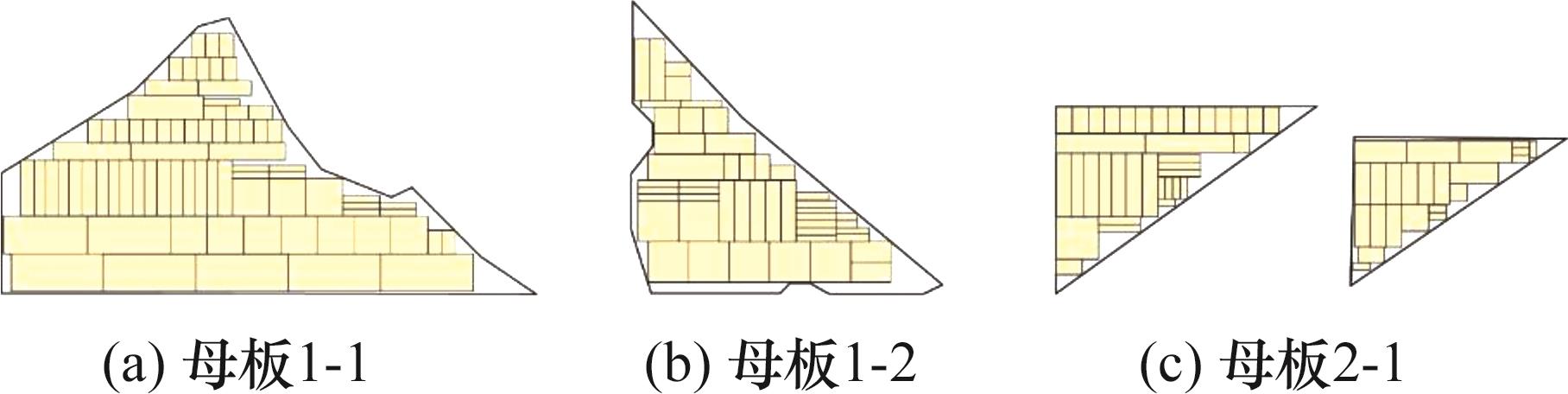

图17 ABWO顺序优化算法结合不规则母板滑动策略下的矩形排样结果

Fig.17 The results of rectangular layout based on irregular plate sliding strategy combined with ABWO sequential optimization algorithm

| [1] | 韩伟, 张子成. 基于模拟退火的贯通约束不规则排样[J]. 中国机械工程, 2016, 27(24):3326-3331. |

| HAN Wei, ZHANG Zicheng. Through Constrained Irregular Nesting Based on Simulated Annealing [J]. China Mechanical Engineering, 2016, 27(24):3326-3331. | |

| [2] | GUO B S, HU J W, WU F H, et al. Automatic Layout of 2D Free-form Shapes Based on Geometric Similarity Feature Searching and Fuzzy Matching[J]. Journal of Manufacturing Systems, 2020, 56:37-49. |

| [3] | 贾志欣, 殷国富, 罗阳. 二维不规则零件排样问题的遗传算法求解[J]. 计算机辅助设计与图形学学报, 2002, 14(5):467-470. |

| JIA Zhixin, YIN Guofu, LUO Yang. Two Dimensional Irregular Parts Packing with Genetic Algorithm[J]. Journal of Computer-aided Design & Computer Graphics, 2002, 14(5):467-470. | |

| [4] | 李满江, 孟祥旭, 王志强. 矩形件和任意多边形排样问题的算法及应用[J]. 贵州工业大学学报(自然科学版), 2002, 31(4):126-130. |

| LI Manjiang, MENG Xiangxu, WANG Zhiqiang. Algorithm and Application of Rectangular and Polygonal Packing Problem[J]. Journal of Guizhou University of Technology (Natural Science Edition), 2002, 31(4):126-130. | |

| [5] | 刘璐. 基于遗传算法的钣金排样系统研究[D]. 西安:西安工业大学, 2014. |

| LIU Lu. Research on Sheet Metal Layout System Based on Genetic Algorithm[D]. Xi'an:Xi'an Technological University, 2014. | |

| [6] | 顾振华, 何援军, 刘胡瑶. 二维不规则图形排料CAD系统的设计[J]. 工程图学学报,2008 (2):17-22. |

| GU Zhenhua, HE Yuanjun, LIU Huyao. The Design of 2D Irregular Nesting CAD System[J]. Journal of Graphics, 2008(2):17-22. | |

| [7] | 袁哲, 邓长亮, 张岩. 不规则凸域板材中单一尺寸矩形排样算法[J]. 沈阳建筑大学学报(自然科学版),2018,34(1):158-164. |

| YUAN Zhe, DENG Changliang, ZHANG Yan. Study on Algorithm of Single Size Rectangular Layout in Irregular Convex Plates[J]. Journal of Shenyang Jianzhu University (Natural Science), 2018, 34(1):158-164. | |

| [8] | YUAN Z, SONG X, AN D, et al. Heuristic Approach for Packing Identical Rectangular Tiles in an Irregular Marble Slab[J]. Mathematical Problems in Engineering, 2022, 2022:1-13. |

| [9] | CHEN K, ZHUANG J, ZHONG S, et al. Optimization Method for Guillotine Packing of Rectangular Items within an Irregular and Defective Slate[J]. Mathematics (Basel), 2020, 8(11):1914. |

| [10] | 董德威, 颜云辉, 张尧, 等. 矩形件优化排样的自适应遗传模拟退火算法[J]. 中国机械工程, 2013, 24(18):2499-2504. |

| DONG Dewei, YAN Yunhui, ZHANG Yao, et al .Adaptive Genetic Simulated Annealing Algorithm in | |

| Optical Layout of Rectangular Parts[J]. China Mechanical Engineering, 2013, 24(18):2499-2504. | |

| [11] | 梁利东, 钟相强. 粒子群算法在不规则件排样优化中的应用[J]. 中国机械工程, 2010, 21(17):2050-2052. |

| LIANG Lidong, ZHONG Xiangjiang. Applications of Particle Swarm Optimization for Solving Irregular Part Nesting Problems[J]. China Mechanical Engineering, 2010, 21(17):2050-2052. | |

| [12] | MIRJALILI S, MIRJALILI S M, LEWIS A D. Grey Wolf Optimizer[J]. Advances in Engineering Software, 2014, 69:46-61. |

| [13] | 罗强. 基于灰狼算法的矩形优化排样及其在板式家具开料中的应用[D]. 武汉:华中科技大学, 2019. |

| LUO Qiang. Rectangular Layout Optimization Based on Gray Wolf Algorithm and its Application in the Cutting of Panel Furniture[D]. Wuhan:Huazhong University of Science and Technology, 2019. | |

| [14] | 全雪峰, 沈继涛. 基于模拟退火剩余矩形算法的矩形件排样[J]. 软件, 2016, 37(3):27-29. |

| QUAN Xuefeng, SHEN Jitao. Optimum Packing of Rectangles Based on Simulated Annealing and Surplus Rectangle[J]. Software, 2016, 37(3):27-29. | |

| [15] | HAYYOLALAM V, KAZEM A A P. Black Widow Optimization Algorithm:a Novel Meta-heuristic Approach for Solving Engineering Optimization Problems[J]. Engineering Applications of Artificial Intelligence, 2020, 87:1-28. |

| [16] | KARABOGA D, BASTURK B. A Powerful and Efficient Algorithm for Numerical Function Optimization:Artificial Bee Colony(ABC) Algorithm[J]. Journal of Global Optimization, 2007, 39(3):459-471. |

| [17] | ZHANG T Y, SUEN C Y. A Fast Parallel Algorithm for Thinning Digital Patterns[J]. Communications of the ACM, 1984, 27(3):236-239. |

| [1] | 余晗琳, 罗亚波. 掺配车间的双中心物流路径规划[J]. 中国机械工程, 2022, 33(21): 2531-2537. |

| [2] | 程浩, 刘心报, 方昶. 基于混合顺序启发式算法的一维下料问题[J]. 中国机械工程, 2014, 25(16): 2191-2195,2203. |

| [3] | 董德威;颜云辉;张尧;李骏. 矩形件优化排样的自适应遗传模拟退火算法[J]. 中国机械工程, 2013, 24(18): 2499-2504. |

| [4] | 徐宏伟, 张广鹏, 黄玉美, 陈庆涛. 大理石机床床身对主轴箱温度场分布的影响研究[J]. 中国机械工程, 2011, 22(11): 1274-1278. |

| [5] | 朱明华, 范秀敏, 程奂翀, 何其昌. 集装箱装船顺序问题的启发式算法研究 [J]. 中国机械工程, 2010, 21(9): 1066-1070. |

| [6] | 李凯;;马华伟;;杨善林;;. 含作业到达时间的单机调度问题的改进算法[J]. J4, 2008, 19(8): 0-885,. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||