ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (10): 2266-2273.DOI: 10.3969/j.issn.1004-132X.2025.10.013

收稿日期:2024-10-11

出版日期:2025-10-25

发布日期:2025-11-06

通讯作者:

马学忠

作者简介:马学忠*(通信作者),男,1991年生,副教授、博士。研究方向为流体密封技术与润滑理论。E-mail:maxz222@163.com。

基金资助:Received:2024-10-11

Online:2025-10-25

Published:2025-11-06

Contact:

Xuehong MA

摘要:

基于计算流体动力学建立了考虑空化效应的双列反向瑞利台阶型机械密封热流体动力润滑(THD)数值模型,并研究了THD特性和空化流动规律。研究结果表明,在双列反向瑞利台阶中发生大面积空化现象,形成低温区域,进而对液膜端面和密封环体产生了显著的冷却作用;从转速、压力以及槽深的变化规律来看,高速、低压和浅槽时空化面积更大,但空化冷却的水平不仅取决于空化面积,还与空化强度相关;同时,由于润滑介质的液化与汽化,在槽内液膜的破裂和重整边界处形成温度谷值和峰值,并在压差流、剪切流共同作用下形成涡旋流动,且涡旋的边缘位置与空化重生以及高温区结束的位置一致;反向台阶槽槽内大面积空化效应的形成促使密封产生良好的抽吸效应,大大降低了密封泄漏率。

中图分类号:

马学忠, 李聪聪. 双列反向台阶型机械密封空化流动与冷却机理[J]. 中国机械工程, 2025, 36(10): 2266-2273.

Xuehong MA, Congcong LI. Cavitation Flow and Cooling Mechanism in Mechanical Seals with Double Row Reverse Step[J]. China Mechanical Engineering, 2025, 36(10): 2266-2273.

| 参数名称 | 数值 | 参数名称 | 数值 |

|---|---|---|---|

| 密封环内径 ri | 47 mm | IRRS主槽深度h4 | 40 μm |

| 密封环外径ro | 57 mm | ORRS内径r1 | 48 mm |

| RS主槽圆周角γ | 21° | IRRS内径r2 | 51 mm |

| RS和RRS引流槽圆周角ϕ | 1.5° | RS内径r3 | 54 mm |

| 密封间隙ho | 6 μm | 进口压力pi | 1 MPa |

| 引流槽深度h1 | 100 μm | 空化压力pc | 30 kPa |

| RS主槽深度h2 | 10 μm | 环境压力po | 0.1 MPa |

| ORRS主槽深度h3 | 50 μm | 密封介质 | 水 |

表1 几何及操作参数

Tab.1 Geometric and operational parameters

| 参数名称 | 数值 | 参数名称 | 数值 |

|---|---|---|---|

| 密封环内径 ri | 47 mm | IRRS主槽深度h4 | 40 μm |

| 密封环外径ro | 57 mm | ORRS内径r1 | 48 mm |

| RS主槽圆周角γ | 21° | IRRS内径r2 | 51 mm |

| RS和RRS引流槽圆周角ϕ | 1.5° | RS内径r3 | 54 mm |

| 密封间隙ho | 6 μm | 进口压力pi | 1 MPa |

| 引流槽深度h1 | 100 μm | 空化压力pc | 30 kPa |

| RS主槽深度h2 | 10 μm | 环境压力po | 0.1 MPa |

| ORRS主槽深度h3 | 50 μm | 密封介质 | 水 |

| 参数名称 | 数值 |

|---|---|

| 动环材料 | 不锈钢 |

| 静环材料 | 碳石墨 |

| 动环热导率kr | 15 W/(m·K) |

| 静环热导率ks | 20 W/(m·K) |

| 动环质量热容cr | 500 J/(kg·K) |

| 静环质量热容cs | 670 J/(kg·K) |

| 黏温系数αT | 0.0175 K-1 |

| 冲洗液速度Uf | 7 m/s |

| 介质温度T0 | 303.15 K |

| 环境温度TL | 303.15 K |

表2 THD物性参数

Tab.2 THD physical property parameters

| 参数名称 | 数值 |

|---|---|

| 动环材料 | 不锈钢 |

| 静环材料 | 碳石墨 |

| 动环热导率kr | 15 W/(m·K) |

| 静环热导率ks | 20 W/(m·K) |

| 动环质量热容cr | 500 J/(kg·K) |

| 静环质量热容cs | 670 J/(kg·K) |

| 黏温系数αT | 0.0175 K-1 |

| 冲洗液速度Uf | 7 m/s |

| 介质温度T0 | 303.15 K |

| 环境温度TL | 303.15 K |

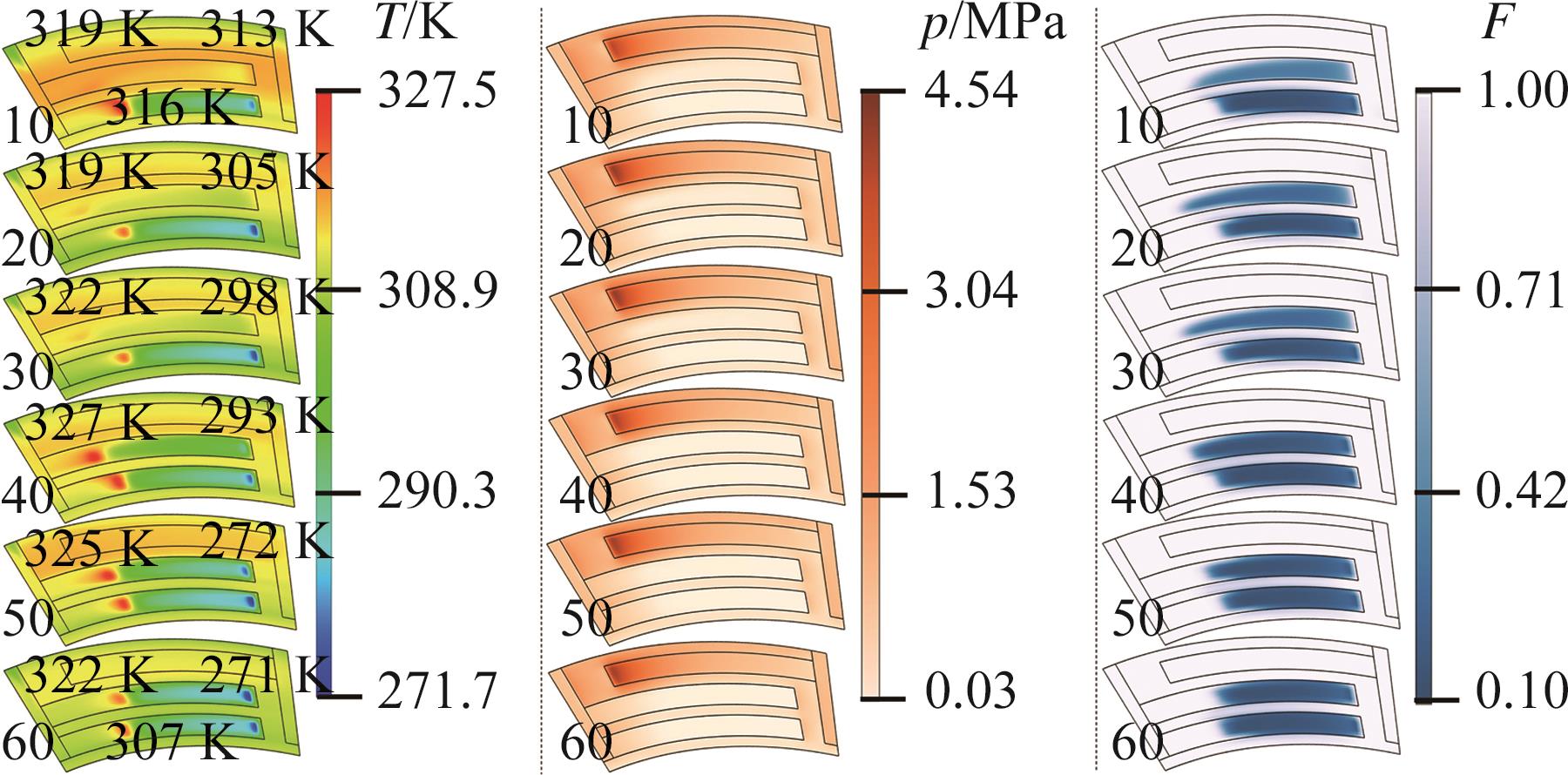

图12 不同ORRS主槽槽深下液膜温度、压力以及液体体积分数分布

Fig.12 Distribution of liquid film temperature, pressure, and liquid volume fraction under different ORRS main groove depths

| [1] | WANG Y, WU J H, XU L. Influence of Turbulent Cavitating Flow on Performance Characteristics of Spiral Groove Liquid Film Seal[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2022, 236(1):70-79. |

| [2] | LI Z, YIN X, YUE J, et al. Effects of Operating Conditions on Cavitation Induction of Spiral Groove Liquid-Film Seal (SG-LFS)[J]. Industrial Lubrication and Tribology, 2020, 72(10):1267-1275. |

| [3] | PASCOVICI M D, PREDESCU A, CICONE T, et al. Experimental Evidence of Cavitational Effects in a Rayleigh Step Slider[J]. Proceedings of the Institution of Mechanical Engineers, Part J:Journal of Engineering Tribology, 2011, 225(6):527-537. |

| [4] | 马学忠, 孟祥铠, 王玉明, 等. 雷列台阶-环槽端面密封机理与性能研究[J]. 摩擦学学报, 2016, 36(5):585-591. |

| MA Xuezhong, MENG Xiangkai, WANG Yuming, et al. Mechanism and Performance of End Face Seal of Rayleigh Steps and Annular Grooves[J]. Tribology, 2016, 36(5):585-591. | |

| [5] | XIE J, MA C, BAI S. Thermo-distortion Characteristics of Spiral Groove Gas Face Seal at High Temperature[J]. Numerical Heat Transfer, Part B:Fundamentals, 2020, 77(3):242-256. |

| [6] | 张肖寒. 液膜润滑机械密封湍流效应研究[D]. 杭州:浙江工业大学, 2021. |

| ZHANG Xiaohan. Study on Turbulent Effect of Liquid Film Lubricated Mechanical Seals[D]. HangZhou:Zhejiang University of Technology, 2021. | |

| [7] | 马学忠,崔元召,肖晓鑫,等.高速机械密封端面引流槽-环槽复合通道冷却特性与密封性能研究[J].润滑与密封, 2025,50(2):1-10. |

| MA Xuezhong, CUI Yuanzhao, XIAO Xiaoxin, et al. Cooling Characteristics and Sealing Performance of the Inlet Groove-annular Groove Composite Channel in High Speed Mechanical Seals[J]. Lubrication Engineering, 2025,50(2):1-10. | |

| [8] | 刘欢欢, 张秋翔, 李双喜, 等. 低温液氧 T 型槽密封端面流场数值模拟[J]. 机械设计与制造, 2014 (11):150-154. |

| LIU Huanhuan, ZHANG Qiuxiang, LI Shuangxi, et al. Numerical Simulation of End Face Flow Field in T-groove Seal with Cryogenic Liquid Oxygen[J]. Machinery Design and Manufacture, 2014 (11):150-154. | |

| [9] | ADJEMOUT M, BRUNETIERE N, BOUYER J. Friction and Temperature Reduction in a Mechanical Face Seal by a Surface Texturing:Comparison Between TEHD Simulations and Experiments[J]. Tribology Transactions, 2018, 61(6):1084-1093. |

| [10] | 马学忠, 赵吉军, 张伟政. 高速深螺旋槽机械密封端面环形槽降温传热机理分析[J]. 工程科学与技术, 2024,56(6):293-302. |

| MA Xuezhong, ZHAO Jijun, ZHANG Weizheng. Cooling Characteristics and Sealing Performance of the Inlet Groove-annular Groove Composite Channel in High Speed Mechanical Seals[J]. Advanced Engineering Sciences, 2024,56(6):293-302. | |

| [11] | QIU Y, MENG X, LIANG Y, et al. Thermal Mixing Effect and Heat Transfer in U-shaped Notch on the Mechanical Seal Face[J]. Proceedings of the Institution of Mechanical Engineers, Part J:Journal of Engineering Tribology, 2021, 235(9):1924-1936. |

| [12] | MENG X. Viscosity Wedge Effect of Dimpled Surfaces Considering Cavitation Effect[J]. Tribology International, 2018, 122:58-66. |

| [13] | LI Y, ZHANG Z, HE Y, et al. Research on Internal Flow Field Characteristics of Straight-groove Texture Using Three-dimensional Modeling[J]. Lubricants, 2023,11(8):338. |

| [14] | QIU M, BAILRY B N, STOLL R, et al. The Accuracy of the Compressible Reynolds Equation for Predicting the Local Pressure in Gas-lubricated Textured Parallel Slider Bearings[J]. Tribology international, 2014, 72:83-89. |

| [15] | 陈汇龙, 王彬, 任坤腾, 等. 空化热效应对上游泵送机械密封润滑性能的影响[J]. 化工学报, 2016, 67(10):4334-4343. |

| CHEN Huilong, WANG Bin, REN Kunteng, et al. Influence of Cavitation Thermal Effect on Lubrication Properties of Upstream Pumping Mechanical Seal[J]. CIESC Journal, 2016, 67(10):4334-4343. | |

| [16] | CROSS A T, SADEGHI F, RATEICK Jr R G, et al. Temperature Distribution in Pocketed Thrust Washers[J]. Tribology Transactions, 2015, 58(1):31-43. |

| [17] | WANG J, LEI L, LI J, et al. Effect of Two-phase Flow Lubrication on Sealing Performance of Spiral Groove Mechanical Seal under High Speed and Low Temperature Conditions[J]. Advances in Mechanical Engineering, 2024, 16(4):16878132241248154. |

| [18] | BRUNETIERE N. A Modified Turbulence Model for Low Reynolds Numbers:Application to Hydrostatic Seals[J]. Journal of Tribology—Transactions of the ASME, 2005, 127(1):130-140. |

| [19] | QIU Y F, KHONSARI M M. Thermohydrodynamic Analysis of Spiral Groove Mechanical Face Seal for Liquid Applications[J]. Journal of Tribology—Transactions of the ASME, 2012,134(2):021703. |

| [20] | 李京浩. 机械密封空化效应的数值计算方法与实验研究[D]. 北京:清华大学, 2011. |

| LI Jinghao. Numerical Computing Method and Experimental Study for Cavitation in Mechanical Seals[D]. Beijing:Tsinghua University, 2011. | |

| [21] | ZHANG J, MENG Y. Direct Observation of Cavitation Phenomenon and Hydrodynamic Lubrication Analysis of Textured Surfaces[J]. Tribology Letters, 2012, 46:147-158. |

| [1] | 饶远1, 孙见君1, 闻兰2. 扩压式自泵送机械密封端面的液膜汽化及其结构优化研究[J]. 中国机械工程, 2025, 36(05): 933-941,953. |

| [2] | 杨艺潇, 孙丹, 兰可心, 赵欢, 冯毓钟, 张杰一, . 基于摩擦热效应的刷式密封摩擦副匹配性实验研究[J]. 中国机械工程, 2024, 35(04): 636-645,690. |

| [3] | 余旻丰, 彭旭东, 孟祥铠, 梁杨杨. 接触式机械密封外圆周织构强化换热机理研究[J]. 中国机械工程, 2023, 34(11): 1268-1279. |

| [4] | 曹生照, 常涛, 郝木明, 孙鑫晖, 王增丽, 任宝杰. 双列螺旋槽液膜密封的相变流动特性[J]. 中国机械工程, 2022, 33(01): 45-53. |

| [5] | 钟明君, 王克鲁, 程静, 欧阳德来, 崔霞, 李鑫. TNTZ钛合金流变行为及物理基本构模型[J]. 中国机械工程, 2021, 32(10): 1233-1239. |

| [6] | 陈汇龙;桂铠;李新稳;韩婷;谢晓凤;陆俊成. 工况参数对机械密封液膜汽化特性及性能的影响[J]. 中国机械工程, 2021, 32(01): 2-11. |

| [7] | 徐鲁帅1;王赟磊1;张帆1;郝木明2;袁小阳1. 螺旋槽机械密封瞬态启动过程润滑特性[J]. 中国机械工程, 2020, 31(16): 1891-1900. |

| [8] | 王建磊1;王晓虎1;张琛1;贾谦2;陈润霖1;刘凯1. 机械密封润滑膜分布的超声检测技术[J]. 中国机械工程, 2019, 30(06): 684-689. |

| [9] | 汪朝晖1;胡亚男1;饶长健1;邓晓刚2. 自激振荡脉冲喷嘴空化效应及其射流形态的数值分析[J]. 中国机械工程, 2017, 28(13): 1535-1541. |

| [10] | 张浩, 孙见君, 马晨波, 涂桥安. 机械密封端面形貌的三维重建及其表征[J]. 中国机械工程, 2017, 28(11): 1287-1291,1299. |

| [11] | 付宇明;王俊丽;张帅;郑丽娟. 半埋藏裂纹金属构件脉冲放电相变应力分析[J]. 中国机械工程, 2013, 24(21): 2944-2947,2954. |

| [12] | 王技德1, 张国渊2. 非接触机械密封的非线性动特性系数及瞬态振动响应分析[J]. 中国机械工程, 2012, 23(6): 642-646. |

| [13] | 王平, 白象忠. 电热止裂相变应力及其对止裂效果的影响 [J]. 中国机械工程, 2011, 22(8): 980-984. |

| [14] | 何龙标, 李路明, 吴敏生. 电弧超声对焊接过程热量传递的影响 [J]. 中国机械工程, 2010, 21(02): 225-228. |

| [15] | 白少先;彭旭东;孟永钢;温诗铸;. 硬盘/磁头薄膜气体润滑中热效应影响分析[J]. J4, 2009, 20(01): 0-4. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||