ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (9): 2097-2107.DOI: 10.3969/j.issn.1004-132X.2025.09.022

• 服务型制造 • 上一篇

收稿日期:2024-05-19

出版日期:2025-09-25

发布日期:2025-10-15

通讯作者:

蒋芳

作者简介:杨涛,男,1985年生,副教授。研究方向为企业管理、传统制造企业转型、商业模式创新、智能制造。E-mail:tyangg-mail@ctbu.edu.cn基金资助:Received:2024-05-19

Online:2025-09-25

Published:2025-10-15

Contact:

Fang JIANG

摘要:

针对传统云制造模式下协同服务主体评价过程中存在的评价指标选取不全面、评价信息处理不合理等问题,提出了一种基于粗数-灰色关联度分析(R-GRA)的云制造协同服务主体评价新方法。首先,综合考虑云制造服务主体的生产能力、经济能力、组织能力、风险应对能力和可持续发展能力,系统建立了包含多个子指标的云制造协同服务主体评价指标体系,并运用熵权法度量指标权重;然后,考虑到协同服务主体评价过程中评价信息的模糊性与不确定性,构建了基于R-GRA的云制造协同服务主体评价模型,并通过融入上述评价指标权重信息,计算各协同服务主体粗数区间差异系数,输出最优协同服务主体评价结果。最后,以某电子医疗器械云制造为例,验证所提模型的科学性、合理性和有效性。

中图分类号:

杨涛, 蒋芳. 基于R-GRA的云制造协同服务主体评价研究[J]. 中国机械工程, 2025, 36(9): 2097-2107.

Tao YANG, Fang JIANG. Research on Evaluations of Cloud Manufacturing Collaborative Service Entities Based on R-GRA[J]. China Mechanical Engineering, 2025, 36(9): 2097-2107.

| 序号 | 子任务 | |

|---|---|---|

| Y1 | 设计和研发 | 外观设计 |

| 功能设计 | ||

| 性能优化 | ||

| Y2 | 零部件制造 | 外壳 |

| 电子部件 | ||

| 传感器 | ||

| 控制部件 | ||

| 光源 | ||

| 光导光纤 | ||

| 光导手柄 | ||

| 光导连接器 | ||

| 光导配件 | ||

| 手术器械 | ||

| 控制器 | ||

| 电源 | ||

| Y3 | 组件装配 | 组装 |

| Y4 | 质量控制 | 产品测试 |

| 质量控制 | ||

| Y5 | 标识和包装 | 产品包装 |

| Y6 | 配送和交付 | 成品交付客户 |

表2 Z公司电子医疗器械子任务统计表

Tab.2 Z Company electronic medical device subtask statistics

| 序号 | 子任务 | |

|---|---|---|

| Y1 | 设计和研发 | 外观设计 |

| 功能设计 | ||

| 性能优化 | ||

| Y2 | 零部件制造 | 外壳 |

| 电子部件 | ||

| 传感器 | ||

| 控制部件 | ||

| 光源 | ||

| 光导光纤 | ||

| 光导手柄 | ||

| 光导连接器 | ||

| 光导配件 | ||

| 手术器械 | ||

| 控制器 | ||

| 电源 | ||

| Y3 | 组件装配 | 组装 |

| Y4 | 质量控制 | 产品测试 |

| 质量控制 | ||

| Y5 | 标识和包装 | 产品包装 |

| Y6 | 配送和交付 | 成品交付客户 |

| 协同服务主体编号 | 企业 历史 | 员工 数量 | … | 平均生产时间 | 单位制造成本 | … |

|---|---|---|---|---|---|---|

| X1 | 5 | 227 | … | 8 | 775 | … |

| X2 | 4 | 180 | … | 10 | 680 | … |

| X3 | 7 | 470 | … | 15 | 845 | … |

| ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ |

| X8 | 3 | 450 | … | 9 | 890 | … |

| X9 | 5 | 528 | … | 19 | 730 | … |

| X10 | 6 | 355 | … | 17 | 760 | … |

表3 子任务1候选协同服务主体集部分信息化数据

Tab.3 Partial information on the candidate collaborative service entities for subtask 1

| 协同服务主体编号 | 企业 历史 | 员工 数量 | … | 平均生产时间 | 单位制造成本 | … |

|---|---|---|---|---|---|---|

| X1 | 5 | 227 | … | 8 | 775 | … |

| X2 | 4 | 180 | … | 10 | 680 | … |

| X3 | 7 | 470 | … | 15 | 845 | … |

| ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ |

| X8 | 3 | 450 | … | 9 | 890 | … |

| X9 | 5 | 528 | … | 19 | 730 | … |

| X10 | 6 | 355 | … | 17 | 760 | … |

| 一级指标 | 权重 | 二级指标 | 权重 |

|---|---|---|---|

| A | 0.417 | A1 | 0.0143 |

| A2 | 0.0992 | ||

| A3 | 0.0897 | ||

| B | 0.245 | B1 | 0.0413 |

| B2 | 0.0355 | ||

| B3 | 0.0974 | ||

| B4 | 0.0421 | ||

| C | 0.379 | C1 | 0.0986 |

| C2 | 0.0776 | ||

| C3 | 0.0974 | ||

| C4 | 0.0452 | ||

| C5 | 0.1031 | ||

| ︙ | ︙ | ︙ | ︙ |

| R | 0.117 | R1 | 0.0244 |

| R2 | 0.0197 | ||

| R3 | 0.0211 | ||

| R4 | 0.0317 | ||

| R5 | 0.0197 | ||

| S | 0.258 | S1 | 0.0966 |

| S2 | 0.0842 | ||

| S3 | 0.0412 | ||

| S4 | 0.0427 | ||

| T | 0.336 | T1 | 0.0381 |

| T2 | 0.0416 | ||

| T3 | 0.0512 | ||

| T4 | 0.0946 | ||

| T5 | 0.0725 |

表4 评价指标权重信息表

Tab.4 Weight information of evaluation indicators

| 一级指标 | 权重 | 二级指标 | 权重 |

|---|---|---|---|

| A | 0.417 | A1 | 0.0143 |

| A2 | 0.0992 | ||

| A3 | 0.0897 | ||

| B | 0.245 | B1 | 0.0413 |

| B2 | 0.0355 | ||

| B3 | 0.0974 | ||

| B4 | 0.0421 | ||

| C | 0.379 | C1 | 0.0986 |

| C2 | 0.0776 | ||

| C3 | 0.0974 | ||

| C4 | 0.0452 | ||

| C5 | 0.1031 | ||

| ︙ | ︙ | ︙ | ︙ |

| R | 0.117 | R1 | 0.0244 |

| R2 | 0.0197 | ||

| R3 | 0.0211 | ||

| R4 | 0.0317 | ||

| R5 | 0.0197 | ||

| S | 0.258 | S1 | 0.0966 |

| S2 | 0.0842 | ||

| S3 | 0.0412 | ||

| S4 | 0.0427 | ||

| T | 0.336 | T1 | 0.0381 |

| T2 | 0.0416 | ||

| T3 | 0.0512 | ||

| T4 | 0.0946 | ||

| T5 | 0.0725 |

| 评价指标 | 决策群体 | ||||

|---|---|---|---|---|---|

| Z1 | Z2 | Z3 | Z4 | Z5 | |

| A | 7 | 5 | 3 | 7 | 5 |

| B | 9 | 7 | 7 | 5 | 9 |

| C | 7 | 5 | 5 | 3 | 3 |

| ︙ | ︙ | ︙ | ︙ | ︙ | ︙ |

| R | 5 | 5 | 7 | 7 | 3 |

| S | 7 | 7 | 3 | 3 | 5 |

| T | 5 | 7 | 5 | 3 | 3 |

表5 候选协同服务主体X1的初始评价矩阵G1

Tab.5 Initial evaluation matrix G1 for candidate collaborative service entity X1

| 评价指标 | 决策群体 | ||||

|---|---|---|---|---|---|

| Z1 | Z2 | Z3 | Z4 | Z5 | |

| A | 7 | 5 | 3 | 7 | 5 |

| B | 9 | 7 | 7 | 5 | 9 |

| C | 7 | 5 | 5 | 3 | 3 |

| ︙ | ︙ | ︙ | ︙ | ︙ | ︙ |

| R | 5 | 5 | 7 | 7 | 3 |

| S | 7 | 7 | 3 | 3 | 5 |

| T | 5 | 7 | 5 | 3 | 3 |

| 协同服务主体 | A | B | C | … | R | S | T |

|---|---|---|---|---|---|---|---|

| X1 | [4.49,6.28] | [6.49,8.28] | [4.55,5.47] | … | [4.49,6.28] | [4.20,6.06] | [4.64,5.50] |

| X2 | [5.13,5.64] | [4.54,7.74] | [1.72,3.50] | … | [3.66,5.40] | [3.32,4.28] | [3.93,6.06] |

| X3 | [6.30,7.70] | [4.49,6.28] | [2.84,5.50] | … | [3.64,5.56] | [3.93,6.06] | [5.32,6.28] |

| ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ |

| X8 | [3.34,5.12] | [4.30,5.64] | [6.49,7.64] | … | [2.96,4.52] | [1.80,4.33] | [2.44,4.36] |

| X9 | [2.54,5.74] | [1.64,3.56] | [5.34,7.12] | … | [4.88,5.70] | [1.32,2.28] | [1.68,5.24] |

| X10 | [7.08,7.72] | [7.72,8.68] | [4.81,7.64] | … | [1.08,1.44] | [3.16,4.44] | [4.36,7.18] |

表6 评审专家综合评价值矩阵

Tab.6 Comprehensive evaluation matrix by review experts

| 协同服务主体 | A | B | C | … | R | S | T |

|---|---|---|---|---|---|---|---|

| X1 | [4.49,6.28] | [6.49,8.28] | [4.55,5.47] | … | [4.49,6.28] | [4.20,6.06] | [4.64,5.50] |

| X2 | [5.13,5.64] | [4.54,7.74] | [1.72,3.50] | … | [3.66,5.40] | [3.32,4.28] | [3.93,6.06] |

| X3 | [6.30,7.70] | [4.49,6.28] | [2.84,5.50] | … | [3.64,5.56] | [3.93,6.06] | [5.32,6.28] |

| ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ |

| X8 | [3.34,5.12] | [4.30,5.64] | [6.49,7.64] | … | [2.96,4.52] | [1.80,4.33] | [2.44,4.36] |

| X9 | [2.54,5.74] | [1.64,3.56] | [5.34,7.12] | … | [4.88,5.70] | [1.32,2.28] | [1.68,5.24] |

| X10 | [7.08,7.72] | [7.72,8.68] | [4.81,7.64] | … | [1.08,1.44] | [3.16,4.44] | [4.36,7.18] |

| 协同服务主体 | A | B | C | … | R | S | T |

|---|---|---|---|---|---|---|---|

| X1 | [1.44,3.23] | [0.40,2.19] | [2.17,3.09] | … | [0.00,1.79] | [0,1.96] | [1.68,2.54] |

| X2 | [2.08,2.59] | [0.94,4.14] | [4.14,5.92] | … | [0.88,2.62] | [1.78,2.74] | [1.12,3.25] |

| X3 | [0.02,1.42] | [2.40,4.19] | [2.14,4.80] | … | [0.72,2.64] | [0,2.13] | [0.90,1.86] |

| ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ |

| X8 | [2.60,5.38] | [3.04,4.38] | [0,1.15] | … | [1.76,3.32] | [1.73,4.26] | [2.82,4.74] |

| X9 | [1.98,5.18] | [5.12,7.04] | [0.52,2.30] | … | [0.58,1.40] | [3.78,4.74] | [1.94,5.50] |

| X10 | [0,0.64] | [0, 0.96] | [0,2.83] | … | [4.84,5.20] | [1.62,2.90] | [0,2.82] |

表7 候选协同服务主体差异系数矩阵

Tab.7 Candidate collaborative service entities difference coefficient matrix

| 协同服务主体 | A | B | C | … | R | S | T |

|---|---|---|---|---|---|---|---|

| X1 | [1.44,3.23] | [0.40,2.19] | [2.17,3.09] | … | [0.00,1.79] | [0,1.96] | [1.68,2.54] |

| X2 | [2.08,2.59] | [0.94,4.14] | [4.14,5.92] | … | [0.88,2.62] | [1.78,2.74] | [1.12,3.25] |

| X3 | [0.02,1.42] | [2.40,4.19] | [2.14,4.80] | … | [0.72,2.64] | [0,2.13] | [0.90,1.86] |

| ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ |

| X8 | [2.60,5.38] | [3.04,4.38] | [0,1.15] | … | [1.76,3.32] | [1.73,4.26] | [2.82,4.74] |

| X9 | [1.98,5.18] | [5.12,7.04] | [0.52,2.30] | … | [0.58,1.40] | [3.78,4.74] | [1.94,5.50] |

| X10 | [0,0.64] | [0, 0.96] | [0,2.83] | … | [4.84,5.20] | [1.62,2.90] | [0,2.82] |

| 主体 | A | B | C | … | R | S | T | D | V |

|---|---|---|---|---|---|---|---|---|---|

| 0.417 | 0.245 | 0.379 | … | 0.117 | 0.258 | 0.336 | |||

| X1 | [0.13,0.37] | [0.04,0.25] | [0.25,0.35] | … | [0,0.20] | [0,0.22] | [0.19,0.29] | [0.482,0.665] | 0.183 |

| X2 | [0.23,0.29] | [0.10,0.47] | [0.47,0.68] | … | [0.10,0.30] | [0.21,0.31] | [0.12,0.37] | [0.314,0.591] | 0.277 |

| X3 | [0,0.16] | [0.27,0.48] | [0.24,0.55] | … | [0.08,0.30] | [0,0.24] | [0.10,0.21] | [0.206,0.522] | 0.316 |

| ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ |

| X8 | [0.29,0.61] | [0.35,0.50] | [0,0.13] | … | [0.20,0.38] | [0.19,0.49] | [0.32,0.54] | [0.345,0.751] | 0.406 |

| X9 | [0.22,0.59] | [0.58,0.81] | [0.05,0.26] | … | [0.06,0.16] | [0.43,0.54] | [0.22,0.63] | [0.233,0.427] | 0.194 |

| X10 | [0,0.07] | [0,0.11] | [0,0.32] | … | [0.55,0.59] | [0.15,0.33] | [0,0.32] | [0.306,0.437] | 0.131 |

表8 标准化处理后的差异化系数

Tab.8 Standardized coefficient of differentiation

| 主体 | A | B | C | … | R | S | T | D | V |

|---|---|---|---|---|---|---|---|---|---|

| 0.417 | 0.245 | 0.379 | … | 0.117 | 0.258 | 0.336 | |||

| X1 | [0.13,0.37] | [0.04,0.25] | [0.25,0.35] | … | [0,0.20] | [0,0.22] | [0.19,0.29] | [0.482,0.665] | 0.183 |

| X2 | [0.23,0.29] | [0.10,0.47] | [0.47,0.68] | … | [0.10,0.30] | [0.21,0.31] | [0.12,0.37] | [0.314,0.591] | 0.277 |

| X3 | [0,0.16] | [0.27,0.48] | [0.24,0.55] | … | [0.08,0.30] | [0,0.24] | [0.10,0.21] | [0.206,0.522] | 0.316 |

| ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ | ︙ |

| X8 | [0.29,0.61] | [0.35,0.50] | [0,0.13] | … | [0.20,0.38] | [0.19,0.49] | [0.32,0.54] | [0.345,0.751] | 0.406 |

| X9 | [0.22,0.59] | [0.58,0.81] | [0.05,0.26] | … | [0.06,0.16] | [0.43,0.54] | [0.22,0.63] | [0.233,0.427] | 0.194 |

| X10 | [0,0.07] | [0,0.11] | [0,0.32] | … | [0.55,0.59] | [0.15,0.33] | [0,0.32] | [0.306,0.437] | 0.131 |

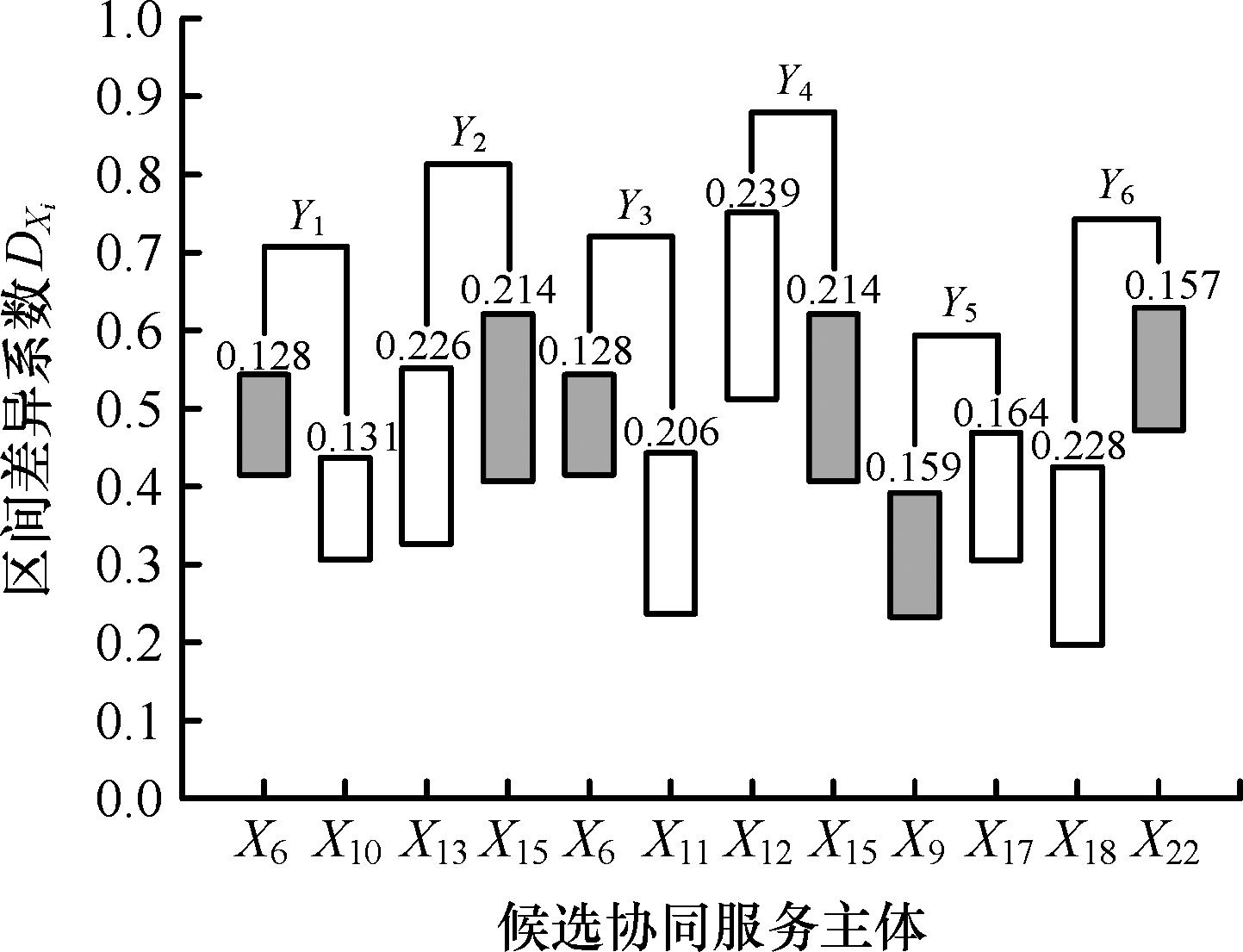

| 子任务 | 候选协同服务主体 | 区间差异系数D | 粗边界区间 V |

|---|---|---|---|

| Y1 | X6 | [0.415,0.543] | 0.128 |

| X10 | [0.306,0.437] | 0.131 | |

| Y2 | X13 | [0.326,0.552] | 0226 |

| X15 | [0.407,0.621] | 0.214 | |

| Y3 | X6 | [0.415,0.543] | 0.128 |

| X11 | [0.237,0.443] | 0.206 | |

| Y4 | X12 | [0.512,0.751] | 0.239 |

| X15 | [0.407,0.621] | 0.214 | |

| Y5 | X9 | [0.233,0.392] | 0.159 |

| X17 | [0.305,0.469] | 0.164 | |

| Y6 | X18 | [0.197,0.425] | 0.228 |

| X22 | [0.472,0.629] | 0.157 |

表9 协同服务主体区间差异系数综合矩阵

Tab.9 Collaborative service entities interval difference coefficient composite matrix

| 子任务 | 候选协同服务主体 | 区间差异系数D | 粗边界区间 V |

|---|---|---|---|

| Y1 | X6 | [0.415,0.543] | 0.128 |

| X10 | [0.306,0.437] | 0.131 | |

| Y2 | X13 | [0.326,0.552] | 0226 |

| X15 | [0.407,0.621] | 0.214 | |

| Y3 | X6 | [0.415,0.543] | 0.128 |

| X11 | [0.237,0.443] | 0.206 | |

| Y4 | X12 | [0.512,0.751] | 0.239 |

| X15 | [0.407,0.621] | 0.214 | |

| Y5 | X9 | [0.233,0.392] | 0.159 |

| X17 | [0.305,0.469] | 0.164 | |

| Y6 | X18 | [0.197,0.425] | 0.228 |

| X22 | [0.472,0.629] | 0.157 |

| 评价结果 | 子任务 | |||||

|---|---|---|---|---|---|---|

| Y1 | Y2 | Y3 | Y4 | Y5 | Y6 | |

| 参与制造 | X6 | X15 | X6 | X15 | X9 | X22 |

| 不参与制造 | X10 | X13 | X11 | X12 | X17 | X18 |

表10 子任务1~子任务6候选协同服务主体评价结果

Tab.10 Analysis of the evaluation results of the candidate collaborative service entities of subtask 1 to subtask 6

| 评价结果 | 子任务 | |||||

|---|---|---|---|---|---|---|

| Y1 | Y2 | Y3 | Y4 | Y5 | Y6 | |

| 参与制造 | X6 | X15 | X6 | X15 | X9 | X22 |

| 不参与制造 | X10 | X13 | X11 | X12 | X17 | X18 |

图5 子任务1~子任务6候选协同服务主体区间差异系数DXi比较示意图

Fig.5 Comparison of the differential coefficient DXi for candidate collaborative service entities from subtask 1 to subtask 6

| [1] | 李伯虎, 张霖, 王时龙, 等. 云制造——面向服务的网络化制造新模式[J]. 计算机集成制造系统, 2010, 16(1):1-7. |

| LI Bohu, ZHANG Lin, WANG Shilong, et al. Cloud Manufacturing:a New Service-oriented Networked Manufacturing Model[J]. Computer Integrated Manufacturing Systems, 2010, 16(1):1-16. | |

| [2] | WU D, ROSEN D W, WANG L, et al. Cloud-based Design and Manufacturing:a New Paradigm in Digital Manufacturing and Design Innovation[J]. Computer-Aided Design, 2015, 59:1-14. |

| [3] | 陆剑峰, 韩调娟, 俞耀平. 基于服务编排的云制造服务协同[J]. 中国机械工程, 2021, 32(7):849-859. |

| LU Jianfeng, HAN Diaojuan, Yu Yaoping. Collaboration of Cloud Manufacturing Service Based on Service Choreography[J]. China Mechanical Engineering, 2021, 32(7):849-859. | |

| [4] | 陈友玲, 牛禹霏, 刘舰, 等. 面向云制造的多供应商协同生产任务分配优化[J]. 计算机集成制造系统, 2019, 25(7):1806-1816. |

| CHEN Youling, NIU Yufei, LIU Jian, et al. Task Distribution Optimization for Multi-supplier Collaborative Production in Cloud Manufacturing[J]. Computer Integrated Manufacturing System, 2019, 25(7):1806-1816. | |

| [5] | 包菊芳, 刘宏程. 基于COWA-云模型的可持续供应链合作伙伴选择[J]. 德州学院学报, 2023, 39(2):57-62. |

| BAO Jufang, LIU Hongcheng. COWA-Cloud Model Based Partner Selection under Sustainable Supply Chain[J]. Journal of Dezhou University, 2023, 39(2):57-62. | |

| [6] | 周向红, 李丹萍, 成鹏飞, 等. 面向云制造协同创新伙伴选择的多源异构VIKOR群决策方法[J]. 计算机集成制造系统, 2022, 28(1):59-72. |

| ZHOU Xianghong, LI Danping, CHENG Pengfei, et al. Multi-source and Heterogeneous VIKOR Group Decision Making Method for Cloud Manufacturing Collaborative Innovation Partner Selection[J]. Computer Integrated Manufacturing System, 2022, 28(1):59-72. | |

| [7] | 潘燕华, 王克, 王平. 云计算环境下复杂产品价值链合作伙伴选择研究[J]. 计算机集成制造系统, 2021, 27(12):3651-3658. |

| PAN Yanhua, WANG Ke, WANG Ping. Partner Selection of Complex Product Value Chain in Cloud Computing[J] Computer Integrated Manufacturing System, 2021, 27(12):3651-3658. | |

| [8] | HU Y, WU,L, SHI C, et al. Research on Optimal Decision-making of Cloud Manufacturing Service Provider Based on Grey Correlation Analysis and TOPSIS[J]. International Journal of Production Research, 2020, 58(3):748-757. |

| [9] | 冉文学, 王志文, 张甜甜. 云服务模式下差异化产品的协同制造企业选择研究[J]. 物流工程与管理, 2023, 45(2):94-99. |

| RAN Wenxue, WANG Zhiwen, ZHANG Tiantian. Research on Collaborative Manufacturing Enterprise Selection of Differentiated Products under Cloud Service Mode[J] Logistics Engineering and Management, 2023, 45(2):94-99. | |

| [10] | TAVAKKOLI-MOGHADDAM R, ALIPOUR-VAEZI M, MOHAMMAD-NAZARI Z. A New Application of Coordination Contracts for Supplier Selection in a Cloud Environment[C]∥ IFIP International Conference on Advances in Production Management Systems(APMS). Novi Sad, 2020:197-205. |

| [11] | 赵金辉, 关文革, 尹立杰. 云制造环境中考虑心理预期的合作伙伴选择[J]. 计算机工程与科学, 2017, 39(6):1193-1200. |

| ZHAO Jinhui, GUAN Wenge, YI Lijie. Selection of Partners Considering Psychological Expectation in Cloud Manufacturing Environment[J]. Computer Engineering & Science, 2017, 39(6):1193-1200. | |

| [12] | 唐春华, 赵爽耀, 黄挺, 等. 基于QoS多方异质评价与供需双约束的云制造服务推荐模型[J]. 计算机集成制造系统, 2023, 29(7):2351-2362. |

| TANG Chunhua, ZHAO Shuangyao, HUANG Ting, et al. Cloud Manufacturing Service Recommendation Model Based on QoS Multi-party Heterogeneous Evaluation and Dual Constraints of Supply and Demand[J]. Computer Integrated Manufacturing System, 2023, 29(7):2351-2362. | |

| [13] | 郭伟, 仝克宁, 邵宏宇, 等. 基于RS与AHP的中小企业云制造模式下多服务主体信用评价体系构建[J]. 计算机集成制造系统, 2013, 19(9):2340-2347. |

| GUO Wei, TONG Kening, SHAO Hongyu, et al. Small and Medium Sized Enterprises Multi-service Agent Credit Rating System Construction under Cloud Manufacturing Mode Based on RS and AHP[J]. Computer Integrated Manufacturing System, 2013, 19(9):2340-2347. | |

| [14] | ZHENG H, FENG Y, TAN J. A Fuzzy QoS-aware Resource Service Selection Considering Design Preference in Cloud Manufacturing System[J]. The International Journal of Advanced Manufacturing Technology, 2016, 84(1):371-379. |

| [15] | 周玉娟, 凌端新, 王秀芹, 等. 中小制造企业数字服务化转型组态路径研究——基于“技术-组织-环境”联动视角[J]. 创新科技, 2025, 25(3):68-81. |

| ZHOU Yujuan, LING Duanxin, WANG Xiuqin, et al. Research on the Configuration Paths of Digital Service Transformation for Small and Medium-sized Manufacturing Enterprises:a Technology-Organization-Environment Framework Perspective[J]. Innovation Science and Technology, 2025, 25(3):68-81. | |

| [16] | YANG C, PENG T, LAN S, et al. Towards IoT-enabled Dynamic Service Optimal Selection in Multiple Manufacturing Clouds[J]. Journal of Manufacturing Systems, 2020, 56:213-226. |

| [17] | YANG T, DING Y, JIANG F. Evaluation of Node Importance in Collaborative Network of Traditional Manufacturing Enterprises Based on Multiple Attribute Decision Making[J]. Decision Making:Applications in Management and Engineering, 2024, 7(2):240-256. |

| [18] | LAILI Y, LIN S, TANG D. Multi-phase Integrated Scheduling of Hybrid Tasks in Cloud Manufacturing Environment[J]. Robotics and Computer-Integrated Manufacturing, 2020, 61:101850. |

| [19] | 伍度志, 杨帆, 赵静. 基于信息熵的加权基因关联网络融合方法[J]. 电子科技大学学报, 2018, 47(2):286-291. |

| WU Duzhi, YANG Fan, ZHAO Jin. Integration of Weighted Gene Association Networks Based on Information Entropy[J]. Journal of University of Electronic Science and Technology of China, 2018, 47(2):286-291. | |

| [20] | 杨涛, 杨育, 薛承梦, 等. 考虑客户需求偏好的产品创新设计方案多属性决策评价[J]. 计算机集成制造系统, 2015, 21(2):417-426. |

| YANG Tao, YANG Yu, XUE Chengmeng, et al. Multi-attribute Decision Making Evaluation Method for Product Innovation Design Scheme with Demand Preferences of Customers[J]. Computer Integrated Manufacturing System, 2015, 21(2):417-426. | |

| [21] | ZHAI L Y, KHOO L P, ZHONG Z W. A Rough Set Enhanced Fuzzy Approach to Quality Function Deployment[J]. The International Journal of Advanced Manufacturing Technology, 2008, 37(5/6):613-624. |

| [22] | ZHAI L Y, KHOO L P, ZHONG Z W. Design Concept Evaluation in Product Development Using Rough Sets and Grey Relation Analysis[J]. Expert Systems with Applications, 2009, 36(3):7072-7079. |

| [23] | 赵文燕, 张换高, 何桢, 等. 粗数——一种客户需求分析方法[J]. 计算机集成制造系统, 2011, 17(11):2493-2501. |

| ZHAO Wenyan, ZHANG Huangao, HE Zhen, et al. Rough Number:Customer Requirements Analytical Method[J]. Computer Integrated Manufacturing System, 2011, 17(11):2493-2501. |

| [1] | 刘繁茂, 廖灿灿, 张原愿, 莫寒. 新型碟式太阳能聚光器跟踪机构优化设计[J]. 中国机械工程, 2023, 34(04): 395-403. |

| [2] | 冯旭刚, 魏舜昊, 魏新园, 徐帅, 樊嵘. 基于信息熵-灰色模糊融合模型的火电机组燃烧检测仪器综合性能评价方法[J]. 中国机械工程, 2022, 33(09): 1098-1103. |

| [3] | 高建平, 余佳衡, 孟垚, 郗建国. 电动车辆控制参数自动优化标定系统的研究及验证[J]. 中国机械工程, 2022, 33(01): 118-125. |

| [4] | 陆剑峰, 韩调娟, 俞耀平. 基于服务编排的云制造服务协同[J]. 中国机械工程, 2021, 32(07): 849-859. |

| [5] | 李阳, 郭飞, 李茂源, 张云, 李德群. [成形过程的数据挖掘与深度学习方法]塑料注射成形智能技术及其应用[J]. 中国机械工程, 2020, 31(22): 2734-2744. |

| [6] | 李强, 汝渴, 刘计良, 张科. [数据驱动的智能服务]面向大规模个性化的交互式云制造模式[J]. 中国机械工程, 2020, 31(07): 788-796. |

| [7] | 和征;张志钊;李勃. 云制造供应链知识转移激励的演化博弈模型[J]. 中国机械工程, 2020, 31(06): 695-705. |

| [8] | 李研彪1,2;王林1,2;罗怡沁1,2;徐梦茹1,2;郑航1,2. 拟人腕关节机构的动载协调分配优化[J]. 中国机械工程, 2019, 30(20): 2480-2488. |

| [9] | 龚小容, 李孝斌, 尹超. [云制造]云制造环境下基于贝叶斯网络的机床装备资源优化决策方法[J]. 中国机械工程, 2018, 29(20): 2438-2445. |

| [10] | 刘伟1,2;商圆圆1,2;邓朝晖1,2;刘仁通1,2. 砂轮表面形貌定量评价及修整效果研究[J]. 中国机械工程, 2018, 29(19): 2277-2283. |

| [11] | 何巍, 贾国柱, 孔继利, 宗恒山. [云制造]基于可持续性的云制造多任务调度[J]. 中国机械工程, 2018, 29(18): 2215-2225. |

| [12] | 刘永奎, 王力翚, 王曦, 徐旬. [云制造]云制造再探讨[J]. 中国机械工程, 2018, 29(18): 2226-2237. |

| [13] | 董元发;吴正佳;杜轩;查靓;袁庆松. 非稳态云制造服务过程资源异常管理方法[J]. 中国机械工程, 2018, 29(10): 1193-1200. |

| [14] | 侯雨雷;魏晓晨;周治宇;曾达幸. 球面并联机构功耗比评价指标及性能分析[J]. 中国机械工程, 2018, 29(01): 89-94,103. |

| [15] | 刘明周, 王强, 凌琳. 基于分层任务网络的云制造任务分解方法[J]. 中国机械工程, 2017, 28(08): 924-930. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||