ISSN 1004-132X

CN 42-1294/TH

CN 42-1294/TH

中国机械工程 ›› 2025, Vol. 36 ›› Issue (11): 2537-2543.DOI: 10.3969/j.issn.1004-132X.2025.11.008

• 机械基础工程 • 上一篇

孙富建1( ), 朱千放1, 梁志强2(

), 朱千放1, 梁志强2( ), 鲁艳军3, 陈金龙1, 肖玉斌4, 黄浩4, 袁剑平4

), 鲁艳军3, 陈金龙1, 肖玉斌4, 黄浩4, 袁剑平4

收稿日期:2024-04-01

出版日期:2025-11-25

发布日期:2025-12-09

通讯作者:

梁志强

作者简介:孙富建,男,1986年生,副教授。研究方向为电脉冲辅助切削加工。E-mail:lancesfj@126.com基金资助:

Fujian SUN1( ), Qianfang ZHU1, Zhiqiang LIANG2(

), Qianfang ZHU1, Zhiqiang LIANG2( ), Yanjun LU3, Jinlong CHEN1, Yubin XIAO4, Hao HUANG4, Jianping YUAN4

), Yanjun LU3, Jinlong CHEN1, Yubin XIAO4, Hao HUANG4, Jianping YUAN4

Received:2024-04-01

Online:2025-11-25

Published:2025-12-09

Contact:

Zhiqiang LIANG

摘要:

淬硬轴承钢恶劣的硬车加工性能显著降低了工件表面完整性,导致淬硬轴承钢摩擦磨损性能较差。基于电脉冲辅助切削技术开展了电脉冲辅助淬硬轴承钢的硬车实验,研究了其表面完整性和表面耐磨性。研究结果表明,相比于传统硬车淬硬轴承钢,电脉冲辅助硬车淬硬轴承钢工件表面完整性得到了显著提高,电脉冲辅助硬车淬硬轴承钢的摩擦因数降低了20%,磨痕宽度和深度分别减小了48.7%和93.33%,显著提高了淬硬轴承钢的摩擦磨损性能。

中图分类号:

孙富建, 朱千放, 梁志强, 鲁艳军, 陈金龙, 肖玉斌, 黄浩, 袁剑平. 电脉冲辅助硬车淬硬轴承钢表面摩擦学性能研究[J]. 中国机械工程, 2025, 36(11): 2537-2543.

Fujian SUN, Qianfang ZHU, Zhiqiang LIANG, Yanjun LU, Jinlong CHEN, Yubin XIAO, Hao HUANG, Jianping YUAN. Research on Tribological Properties of Hardened Bearing Steel Surfaces by Electric Pulse Assisted Hard Turning[J]. China Mechanical Engineering, 2025, 36(11): 2537-2543.

| w(C) | w(Mn) | w(Si) | w(S) | w(P) |

|---|---|---|---|---|

| 0.95~1.05 | 0.2~0.4 | 0.15~0.35 | ≤0.2 | ≤0.027 |

| w(Cr) | w(Mo) | w(Ni) | w(Cu) | w(Ni+Cu) |

| 1.30~1.65 | ≤0.1 | ≤0.3 | ≤0.25 | ≤0.5 |

表1 ZGCr61淬硬轴承钢的化学成分(质量分数) (%)

Tab.1 Chemical composition of ZGCr61 hardened bearing steel (mass fraction)

| w(C) | w(Mn) | w(Si) | w(S) | w(P) |

|---|---|---|---|---|

| 0.95~1.05 | 0.2~0.4 | 0.15~0.35 | ≤0.2 | ≤0.027 |

| w(Cr) | w(Mo) | w(Ni) | w(Cu) | w(Ni+Cu) |

| 1.30~1.65 | ≤0.1 | ≤0.3 | ≤0.25 | ≤0.5 |

| 抗拉强度/MPa | 屈服强度/MPa | 显微硬度 | 伸长率/% |

|---|---|---|---|

| 861.3 | 518.42 | 58HRC | 27.95 |

表2 ZGCr61淬硬轴承钢的力学性能

Tab.2 Mechanical properties of ZGCr61 hardened bearing steel

| 抗拉强度/MPa | 屈服强度/MPa | 显微硬度 | 伸长率/% |

|---|---|---|---|

| 861.3 | 518.42 | 58HRC | 27.95 |

| 组别 | 工件温度θw/℃ | 占空比η/% | 电流密度Jm/(A·mm-2) | 脉冲频率f/Hz |

|---|---|---|---|---|

| 1 | 25 | 50 | 0 | 0 |

| 2 | 25 | 50 | 0.075 | 300 |

| 3 | 25 | 50 | 0.225 | 300 |

表3 电脉冲辅助硬车实验工艺参数

Tab.3 Processing parameters of electric pulse assisted hard turning experiment

| 组别 | 工件温度θw/℃ | 占空比η/% | 电流密度Jm/(A·mm-2) | 脉冲频率f/Hz |

|---|---|---|---|---|

| 1 | 25 | 50 | 0 | 0 |

| 2 | 25 | 50 | 0.075 | 300 |

| 3 | 25 | 50 | 0.225 | 300 |

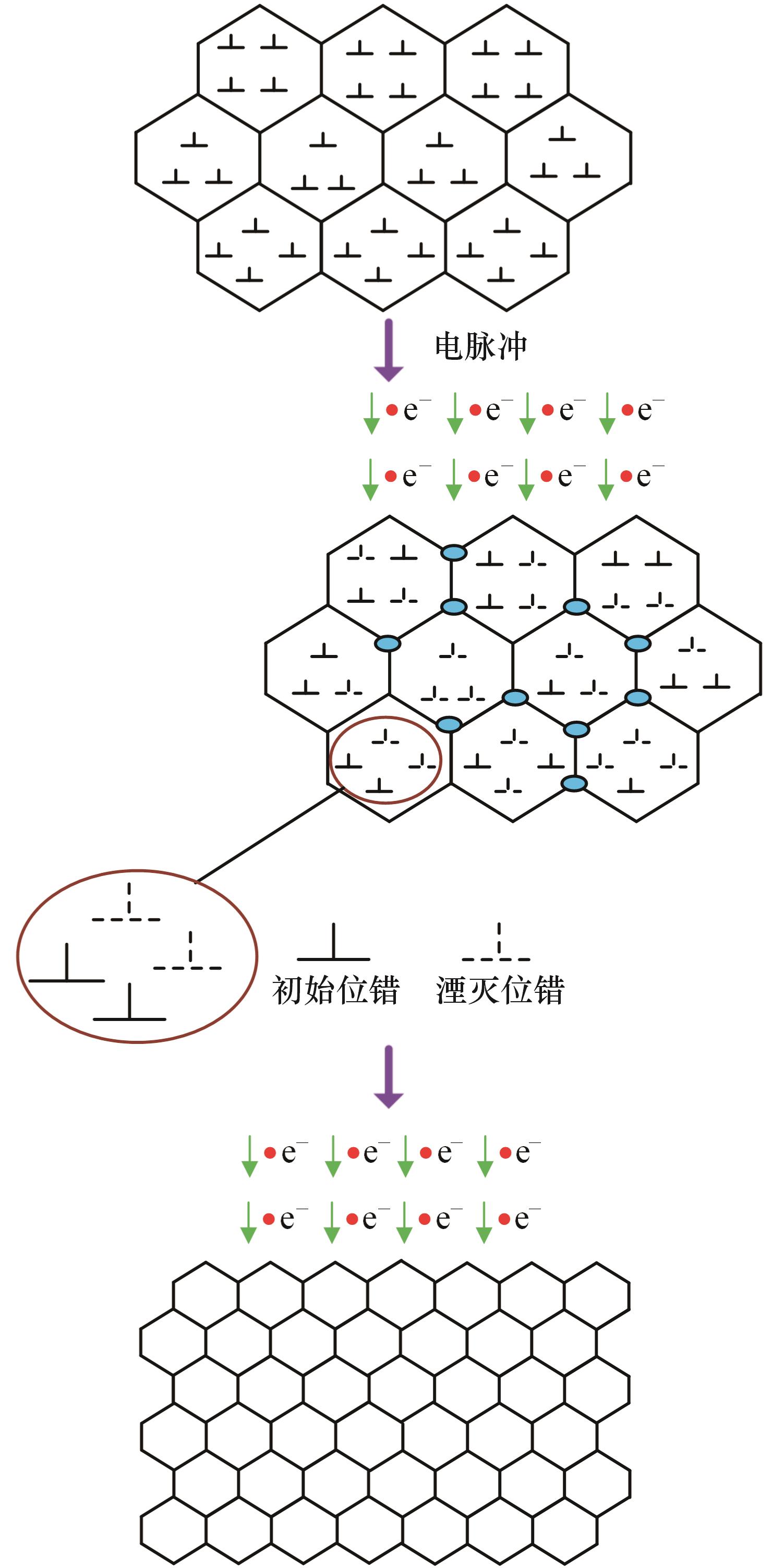

图4 电脉冲辅助硬车工件表面强化层材料动态再结晶的原理

Fig.4 Principle of dynamic recrystallization of workpiece surface strengthened layer by electric pulse assisted hard turning

| [1] | 李素燕,王冠中,韩志民.高速车削淬硬轴承钢切削力试验研究[J].长春工业大学学报, 2017, 38(3): 231-236. |

| LI Suyan, WANG Guanzhong, HAN Zhimin. Experimental Study on Cutting Force on Hardened Bearing Steel in High-speed Turning[J].Journal of Changchun University of Technology,2017,38(3):231-236. | |

| [2] | HUSSAIN G, ALKAHTANI M, ALSULTAN M, et al. Chip Formation, Cutting Temperature and Forces Measurements in Hard Turning of GCr15 under the Influence of PCBN Chamfering Parameters [J]. Measurement, 2022, 204: 112130. |

| [3] | 崔伯第.硬车削淬硬轴承钢GCr15表面粗糙度的试验研究[J].机械设计与制造,2013(7):150-152. |

| CUI Bodi. The Experimental Study of Hard Turning Hardened Bearing Steel GCr15 Surface Roughness[J].Machinery Design & Manufacture,2013(7):150-152. | |

| [4] | 于良,郑光明,张国栋,等.AISI 4340高强钢高速硬车削下PCBN刀具磨损机理[J].组合机床与自动化加工技术,2022(3):161-164. |

| YU Liang, ZHENG Guangmin, ZHANG Guodong,et al. Wear Mechanisms of the PCBN Tool under High-speed Hard Turning of AISI 4340 High Strength Steel[J]. Modular Machine Tool & Automatic Manufacturing Technique,2022(3):161-164. | |

| [5] | WANG J H, ZHANG J, PENG R T, et al. Research on Cutting Parameters of Low-temperature Liquid CO2 Assisted PCD Tool Turning Bearing Ring[J]. Journal of Manufacturing Processes,2023, 87: 199-208. |

| [6] | 郝思洁,褚强,李文亚,等.电脉冲处理对金属材料组织、力学性能影响的研究进展[J].材料导报, 2023, 37(4): 136-144. |

| HAO Sijie, ZHU Qiang, LI Yawen, et al. Effect of Electropulsing Treatment on the Microstructure and Mechanical Properties of Metallic Materials: a Review[J]. Materials Reports, 2023, 37(4):136-144. | |

| [7] | LANG H J, XU Y M, ZHU P Z, et al. Superior Lubrication and Electrical Stability of Graphene as Highly Effective Solid Lubricant at Sliding Electrical Contact Interface[J]. Carbon, 2021, 183: 53-61. |

| [8] | EGEA A J S, ROJAS H A G, MONTAÑA C A M, et al. Effect of Electroplastic Cutting on the Manufacturing Process and Surface Properties[J].Journal of Materials Processing Technology, 2015, 222: 327-334. |

| [9] | 冯耿超,黎小辉,王海波.Ti-6Al-4V合金电脉冲辅助车削加工实验研究[J].材料研究与应用,2022, 16(5): 874-881. |

| FENG Gengchao, LI Xiaohui, WANG Haibo. Experimental Research on Electropulsing-assisted Turning of Ti-6Al-4V Alloy[J].Materials Research and Application, 2022, 16(5): 874-881. | |

| [10] | 王海波.304不锈钢的电脉冲辅助车削与声电耦合表面加工研究[D]. 北京:清华大学, 2017. |

| WANG Haibo. Research on the Electropulsing Assisted Turning and Ultrasonic-electropulsing Coupling Surface Process for the 304 Stainless Steel [D].Beijing:Tsinghua University,2017. | |

| [11] | 李小睿,赵威,李浩,等.高压低温CO2射流冷却条件下高速车削淬硬轴承钢的试验研究[J].中国机械工程,2023,34(24):2975-2985. |

| LI Xiaorui, ZHAO Wei, LI Hao, et al. Experimental Study of High-speed Turning of Hardened Bearing Steels under High-pressure Cryogenic CO2Jet Cooling Conditions[J].China Mechanical Engineering,2023,34(24):2975-2985. | |

| [12] | GOVIND S G, SUDRSHAN S, SANJAY A, et al. Experimental Investigations on the Ultrasonic Vibration-assisted Hard Turning of AISI 52100 Steel Using Coated Carbide Tool[J]. Materials Today: Proceedings, 2022, 68: 2093-2098. |

| [13] | 张硕,王海波,张冰,等.高能电脉冲对淬火态GCr15钢切削性能的影响[J].稀有金属材料与工程,2018,47(2):574-580. |

| ZHANG Shuo, WANG Haibo, ZHANG Bing, et al. Effect of Electropulsing Assisted Cutting Process on Cutting Properties of Quenched GCr15 Bearing Steel[J]. Rare Metal Materials and Engineering, 2018, 47(2): 574-580. | |

| [14] | QU S, ZHAI J, SUN P, et al. Influence of Electropulsing Assisted on Machining Properties of Ti-6Al-4V Titanium Alloy[J]. International Journal of Advanced Manufacturing Technology, 2023, 126: 3161-3174 . |

| [15] | KHATIR F A, SADEGHI M H, AKAR S. Investigation of Surface Integrity in the Laser-assisted Turning of AISI 4340 Hardened Steel[J]. Journal of Manufacturing Processes, 2021, 61: 173-189. |

| [16] | 张翔宇,彭振龙.难加工合金高速高质超声切削加工方法及应用[J].金属加工(冷加工),2023(7): 9-15. |

| ZHANG Xiangyu, PENG Zhenglong. Methods and Applications of High Speed and High Quality Ultrasonic Cutting of Refractory Alloys[J]. Metal Working (Metal Cutting),2023(7): 9-15. | |

| [17] | 潘多. γ-TiAl合金低温冷却切削加工材料去除机理研究[D].济南:济南大学,2023. |

| PAN Duo. Removal Mechanism of γ-TiAl Alloy in Cryogenic Cooling Cutting[D].Jinan:University of Jinan, 2023. | |

| [18] | PENG Z L, ZHANG X Y, ZHANG D Y. Integration of Finishing and Surface Treatment of Inconel718 Alloy Using High-speed Ultrasonic Vibration Cutting[J]. Surface & Coatings Technology,2021, 413: 127088. |

| [19] | WU S X, HE Y K, ZHU T, et al. Microstructure and Mechanical Properties of Superficial Surface and Subsurface Layers in the Cutting of Hardened Steel under Cryogenic Cooling[J]. Journal of Materials Processing Technology, 2023, 322:118165. |

| [20] | GUAN L, TANG G Y, CHU P K,et al .Enhancement of Ductility in Mg-3Al-1Zn Alloy with Tilted Basal Texture by Electropulsing [J].Journal of Materials Research,2009,24(12):3674-3683. |

| [21] | 耿玉波,匡杰,唐国翌,等.高能脉冲电流在AZ31镁合金轧制中的应用研究[J].热加工工艺,2017,46(3):74-78. |

| GENG Yubo, KUANG Jie, TANG Guoyi, et al. Application Study of High Energy Pulse Current in Rolling of AZ31 Magnesium Alloy[J]. Hot Working Technology, 2017,46(3): 74-78. | |

| [22] | 崔通,贺甜甜,杜三明,等.激光冲击强化对G Cr15轴承钢微观组织和摩擦学行为的影响[J].表面技术,2022,51(7):353-362. |

| CUI Tong, HE Tiantian, DU Sanming, et al. Effect of Laser Shock Processing on Microstructure and Tribological Behavior of GCr15 Bearing Steel[J]. Surface Technology, 2022, 51(7): 353-362. | |

| [23] | 张飞,赵运才.超声表面滚压处理对45钢摩擦学性能的影响及机理[J].机械工程材料, 2017, 41(8): 44-48. |

| ZHANG Fei, ZHAO Yuncai. Influence of Ultrasonic Surface Rolling Processing on Tribological Performance of 45 Steel and Its Mechanism[J]. Materials for Mechanical Engineering, 2017, 41(8): 44-48. | |

| [24] | 童佳威,彭锐涛,郝秀清,等.离子液体改性MWCNTs、MoS2及其复合纳米流体的摩擦学性能[J].工程科学学报, 2023, 45 (2): 286-294. |

| TONG Jiawei, PENG Ruitao, HAO Xiuqing, et al. Tribological Properties of Ionic Liquid Modified MWCNTs, MoS2, and Their Composite Nanofluids[J]. Chinese Journal of Engineering,2023,45(2): 286-294. | |

| [25] | WANG J A, CHENG Y, ZHANG Y, et al. Friction and Wear Behavior of Microwave Sintered Al2O3/TiC/GPLs Ceramic Sliding against Bearing Steel and Their Cutting Performance in Dry Turning of Hardened Steel[J]. Ceramics International,2017, 43(17): 14827-14835. |

| [26] | ZHANG L M, LI S S, XIA A N, et al. Fabrication of Polycrystalline Diamond Micro-milling Cutter with Different Grain Sizes by Picosecond Laser[J]. Ceramics International, 2024, 50: 13924-13934. |

| [1] | 范滔1, 2, 姚倡锋1, 2, 谭靓1, 2, 单晨伟1, 2, 夏子文1, 2. γ-TiAl合金的加工特性及能场辅助技术研究进展[J]. 中国机械工程, 2025, 36(04): 636-645. |

| [2] | 何喆1, 李佳乐1, 史恺宁1, 樊昱昌3, 黄新春2. 热机载荷下GH4169G车削喷丸加工表面完整性的演化机理[J]. 中国机械工程, 2025, 36(04): 780-789. |

| [3] | 王栋, 陈磊, 张志鹏. 外圆磨削18CrNiMo7-6力模型及表面完整性研究[J]. 中国机械工程, 2024, 35(03): 381-393. |

| [4] | 勾睿杰, 张晓峰, 张鸿滨, 姚俊, 李勋. 刀具磨损对Allvac 718Plus高温合金铣削加工表面完整性及疲劳性能的影响[J]. 中国机械工程, 2023, 34(24): 2920-2926. |

| [5] | 李小睿, 赵威, 李浩, 史卫奇, 何宁. 高压低温CO2射流冷却条件下高速车削淬硬轴承钢的试验研究[J]. 中国机械工程, 2023, 34(24): 2975-2985. |

| [6] | 吴泽刚, 侯永峰, 苗清, 李靖, 张定华, 罗明, . TC11钛合金整体叶轮铣削加工表面完整性研究[J]. 中国机械工程, 2023, 34(23): 2862-2872. |

| [7] | 李祥, 郑光明, 颜培, 孙作民, 程祥, 刘焕宝. 清洁切削高温合金涂层刀具切削性能及加工表面完整性[J]. 中国机械工程, 2023, 34(04): 454-463. |

| [8] | 季文彬, 邓日清, 戴士杰, 刘春成. 铣削对SLM增材TC4钛合金表面完整性和疲劳性能的影响[J]. 中国机械工程, 2023, 34(02): 208-217,225. |

| [9] | 吴振宇, 郑光明, 颜培, 杨先海, 赵光喜, 李学伟. 表面处理对TiAlSiN涂层刀具表面完整性及切削性能的影响研究[J]. 中国机械工程, 2023, 34(01): 75-83. |

| [10] | 于良, 郑光明, 杨先海, 程祥, 常垲硕, 李学伟. 深冷处理对PCBN刀具切削性能的影响研究[J]. 中国机械工程, 2022, 33(20): 2450-2458. |

| [11] | 王东峰, 袁巨龙, 王燕霜, 程勇杰, 吕冰海. 轴承沟道表面完整性研究进展[J]. 中国机械工程, 2022, 33(18): 2143-2160. |

| [12] | 余建杭, 颜培, 范雷, 顾慧卿, 焦黎, 仇天阳, 王西彬. 相态对镍钛合金清洁切削性能和表面完整性的影响[J]. 中国机械工程, 2022, 33(05): 569-576. |

| [13] | 彭锐涛, 彭兴, 童佳威, 赵林峰, 陈美良, 贺湘波. 水基混合纳米流体对内冷却磨削性能的影响[J]. 中国机械工程, 2021, 32(13): 1591-1599. |

| [14] | 彭锐涛1;吴艳萍1;唐新姿1;鲁鑫焱1;胡云波2. 流道出口位置对加压内冷却砂轮磨削性能的影响[J]. 中国机械工程, 2020, 31(04): 489-497. |

| [15] | 段练1,2;黄云1,2;邹莱1,2. 机器人砂带磨削GH4169镍基高温合金表面完整性研究[J]. 中国机械工程, 2019, 30(17): 2044-2050. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||